Technical exchange | SPCs Technology: solve four construction problems for precast buildings

50) in 2021, it was written that the inspection used the borehole endoscope method to detect the plumpness of sleeve grouting in 22 unit projects, of which the plumpness of 7 projects did not meet the requirements, and the qualified rate was only 68.2%.

Workers who lack professional ethics sometimes cut the reinforcement directly because it is too difficult to align the reinforcement, which will directly lead to major potential safety hazards of the structure.

4.

In the report on the special inspection on the construction quality of cast building structures organized by Shanghai Construction Engineering Safety and quality supervision station (hjazj [2021] No.

It not only retains the traditional cast-in-situ method, but also has the advantages of overall safety, good waterproof performance and high quality.

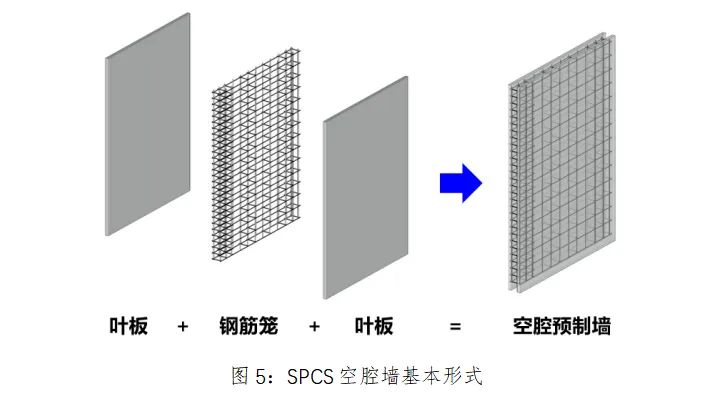

Full prefabrication on both sides refers to the production and prefabrication of concrete slabs on both sides in the factory; The method of full prefabrication on both sides realizes less binding, less formwork erection and less labor on the construction site.

To solve the above problems, the R & D team of Sany Construction Engineering Technology Co., Ltd.

The strong connection of ladder reinforcement refers to the effective connection between ladder reinforcement and vertical longitudinal reinforcement, so that the two panels will not be misplaced due to external force in transportation and construction.

has introduced various processes for the integrated thermal insulation technology, as shown in Figure 10.

This method of large cavity in the middle can reduce the weight of components, increase the size of components, and realize the advantages of less joint, less formwork erection and less binding of large components.

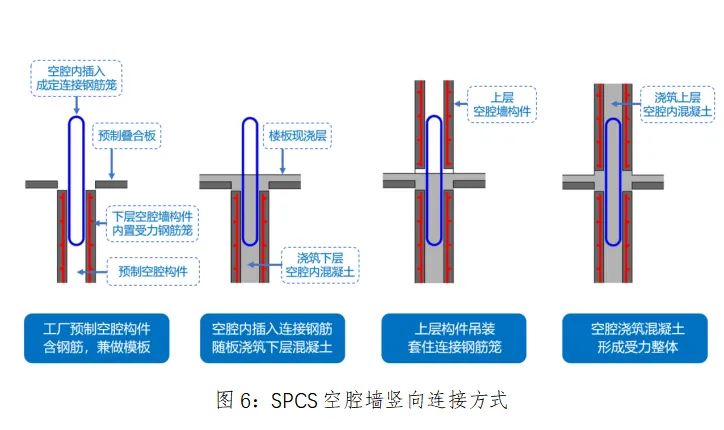

The up-down connection mode of “cavity + lap + post pouring” of SPCs cavity wall (as shown in Figure 6) is a “industrialized post pouring” technology.

3.

No reinforcement on four sides means that the longitudinal and transverse reinforcement in the precast concrete slab on both sides does not extend out of the slab; The method of no reinforcement on all sides realizes the standardization of the mold in the production process, and there is no need to open the reinforcement groove on the mold.

At present, the longest size of SPCs exterior wall components produced by SANY construction can reach 8m and the weight is only more than 3 tons (as shown in Figure 11).

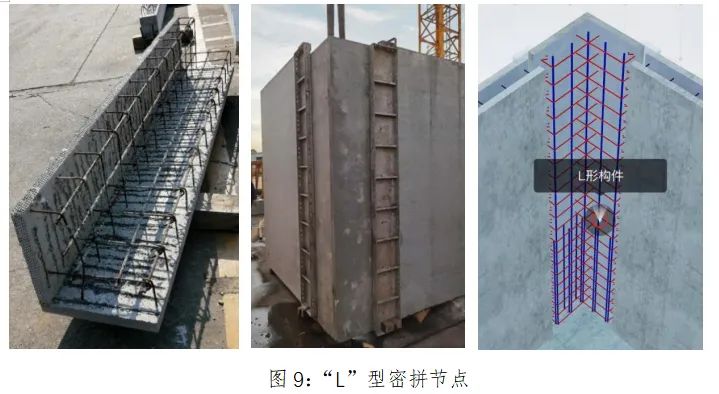

SPCs cavity wall close fitting technology is applicable not only to I-shaped joints (as shown in Figure 8), but also to L-shaped joints (as shown in Figure 9).

(as shown in Figure 12) in addition, due to the light self weight of the components, the position of the SPCs wall can be adjusted more easily, so that there is basically no dislocation between the cast-in-situ joints between the walls and the precast wall..

As shown in Figure 2.

Advantage 5: the quality of finished components looks good.

The structural technical system can give play to many significant technical advantages in the external wall of the building, including good waterproof performance of the external wall, less dense assembly of the external wall, less formwork, integration of thermal insulation, light weight, large size, easy construction, good appearance quality of finished components, and thin plastering.

This technology is difficult to connect the reinforcement alignment.

With the rapid development of precast buildings, the problems of traditional precast buildings in the outer wall are becoming increasingly prominent, including water seepage at the root of the outer wall, difficult alignment of reinforcement, falling off of outer wall insulation board and so on.

Advantage 2: less formwork for close fitting of external wall # SPCs cavity wall can use external wall close fitting technology to realize less formwork for external wall and avoid wrong platform.

Advantage 1: the waterproof performance of the external wall is good.

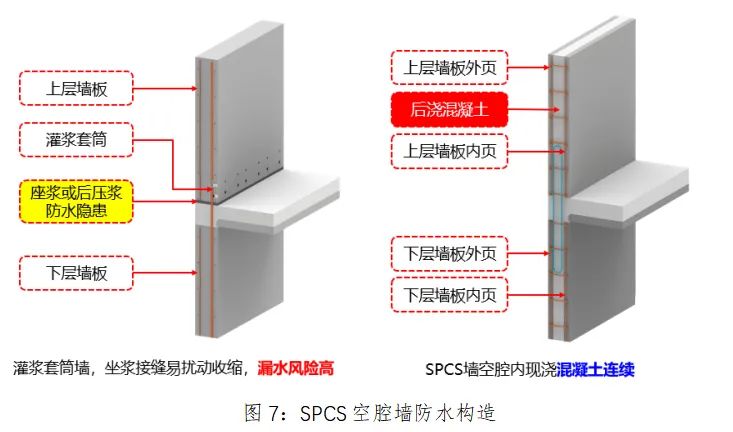

The vertical connection form of SPCs external wall adopts the method of cavity + lap + post pouring to connect up and down (as shown in Figure 6).

2.

It also uses the mode of industrial production to improve the production efficiency and construction efficiency and reduce the construction cost.

At present, the external wall insulation board in the market often falls off and catches fire in a large area due to improper material selection and non-standard construction, which brings serious harm to the safety of people’s lives and property.

Advantage 4: light weight, large size, few joints and easy construction.

Due to the intelligent production of double-sided formwork, the appearance quality of SPCs exterior wall is good, which can achieve the effect of fair faced concrete, and the flatness can be less than 2mm.

The basic form of SPCs cavity wall components is “fully precast on both sides, no reinforcement on four sides, large cavity in the middle and strong connection of ladder reinforcement” (see Figure 5).

The large cavity in the middle refers to the large cavity left in the full precast slab on both sides, which will be poured and compacted with concrete in the construction stage.

has successfully developed the SPCs structure technology system based on the technical route of “cavity lapping, post pouring and finalized mold pouring nodes”.

Find problems and grasp the pain points.

As shown in Figure 3.

The traditional cast wall adopts the vertical connection technology of grouting sleeve.

Due to the internal cavity of SPCs cavity wall, the alignment of vertical lap reinforcement is easier, the hoisting is faster, and the self weight of components is lighter than that of solid wall.

Advantage 3: integration of external wall insulation in order to solve the problems of fire and falling off of traditional external insulation, Sany construction engineering has developed SPCs external wall insulation integration technology, which can realize the integration of external wall insulation, waterproof, fire prevention and structural functions.

Sany Construction Engineering Co., Ltd.

Under the condition that the model of tower crane remains unchanged, the size of SPCs cavity wall can be larger than that of solid wall, so that there are fewer joints between walls, fewer on-site formwork binding and faster construction.

For the traditional PC exterior wall, there is a hidden danger of water seepage at the root of the wall because the sleeve grouting is not easy to compact, or the upper and lower joints of the wall are easy to disturb and shrink, as shown in Figure 1.

In addition, after the installation of SPCs external wall with this technology, there is no need for subsequent external construction, which reduces the risk of high-altitude operation and significantly improves the construction speed.

The advantages are obvious and widely praised.

The installation of a large number of external protective frames greatly increases the project cost.

Traditional cast-in-situ structures need to rent climbing frames or erect external scaffolds in the construction stage for facade formwork support, exterior wall structure repair, exterior wall masonry, facade decoration and other operations (as shown in Figure 4).

1.

This connection form can eliminate the leakage hidden danger of the traditional assembly type and make the precast part closely combined with the cast-in-situ part (as shown in Figure 7).

The traditional solid wall system adopts single-sided formwork production, which requires manual plastering, which not only consumes a lot of man hours, but also the surface production accuracy requiring manual plastering is difficult to control.