Special topic – “Zhongtian exploration” in the development of modern precast buildings

Today, the proportion of precast buildings in concrete structure buildings in the United States accounts for 35%, and the degree of standardization, serialization and commercialization of assembled residential components and parts is close to 100%, and six industrial chains have been formed.

During this period, the industrialization degree of precast concrete in China was significantly improved, and precast components such as precast exterior wall panels, prestressed building covers and prestressed circular orifice plates began to be produced and applied.

After 1990, Germany began to choose the mixed construction system of cast-in-situ and precast components or steel-concrete structure system.

In 1910, the book “housing industrialization” written by German architect Walter Gropius came out.

The forward looking Industry Research Institute, a famous research institution, boldly predicts that when the penetration rate of precast buildings in China reaches 30%, a market of up to two trillion yuan will be formed.

The construction industrialization in Germany and other European developed countries originated in the 1920s.

After World War II, Germany built a large number of residential buildings using precast concrete slab technology.

According to the statistics of the Ministry of housing and urban rural development, in 2020 alone, the new construction area of precast buildings in China reached 630 million square meters, accounting for 20.5% of the new construction area.

The precast concrete structure built according to this system has withstood the test of the Hanshin magnitude 7.3 earthquake.

Since the 20th century, the progress of science and technology and the urbanization process of European and American countries have provided good conditions and market-oriented basis for the development of precast buildings, and a trend of applying precast buildings immediately began.

All its building components are pre assembled in the factory in Pennsylvania and then transported to New York to “build blocks”.

With the acceleration of China’s urbanization, the upgrading of industrial structure and the popularization of the concept of green environmental protection, the construction industry, as the pillar of the national economy, is undergoing rapid development and continuous transformation.

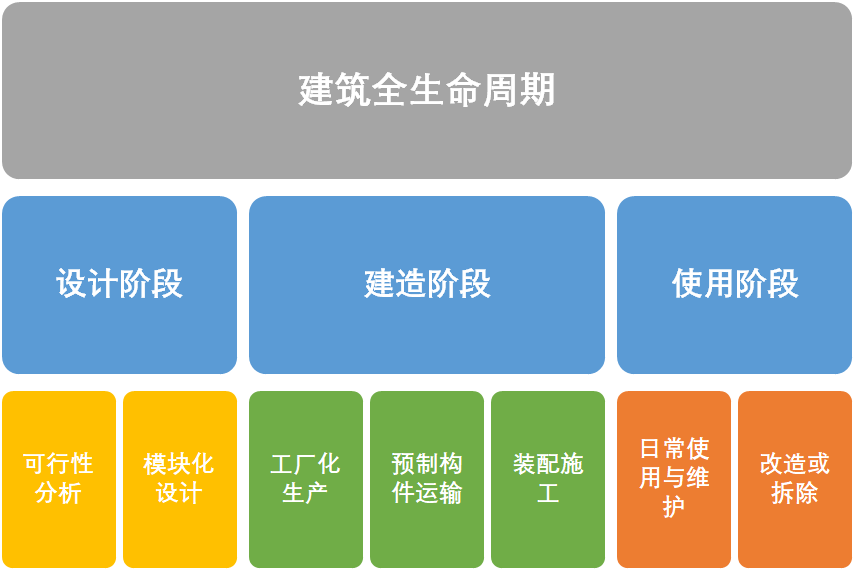

With the application of BIM Technology, the level of building industrialization has been continuously improved.

By the end of 1970, more than 100000 square meters of large formwork houses combined with assembly and prefabrication and precast integral frame structures had been built in Beijing and Tianjin.

Compared with traditional cast-in-situ buildings, precast buildings can shorten the construction cycle by 25-30%, save water by 50-60%, save wood by about 80%, reduce construction energy consumption by about 20%, reduce construction waste by 70% – 80%, and significantly reduce construction dust and noise pollution.

In 1973, the first residence in East Germany built with wbs70 precast slab system.

In 1968, Japan put forward the concept of precast house; In 1990, the “medium and high-rise residential production system” adopting component and industrialized production mode was launched, which was recognized by Japan and the world.

With the continuous development of economy, the market demand for construction industrialization is becoming more and more urgent.

However, compared with foreign countries, China’s construction industry prefers cast-in-situ concrete technology.

As an Asian country, Japan has formulated a number of residential construction plans and relevant bills from 1955 to 1966 to support precast buildings at the legal level.

Through the introduction of Soviet technology, Beijing carried out the construction of precast large brick block experimental residence in 1957.

The Empire State Building in New York, which is 381 meters high and 102 floors, is a representative of precast buildings in the United States.

Up to now, the proportion of precast components of residential buildings in Germany has exceeded 94.5%.

integral prestressed precast slab column system) technical data promoted the research and development of integral prestressed precast slab column construction in China.

The construction process of the Empire State building was built in 1931.

Fixing Socket Cross Pin Nail Plate

The practice of developed countries has proved that high-quality, high-efficiency, energy-saving and environmental friendly precast buildings are not only the inevitable choice to realize the green development of the construction industry, but also the only way for China’s construction industry to embark on the transformation of industrialization..

Precast architecture in the modern sense rose in the era of industrial revolution.

The first Sanmen residential area in Beijing, built in 1976, was adopted The construction system of the combination of wall fire formwork cast-in-situ concrete and external wall precast concrete slab.

The construction speed can reach 4.5 floors per week, and the whole construction period takes only 410 days.

Taking precast buildings as the carrier and jointly promoting intelligent construction and new building industrialization is becoming the leading force leading the change trend of the industry.

From concept to practice, it is constant improvement, perfection and improvement.

In 1959, the precast frame shear wall structure was adopted for the first time in Beijing National Hotel.

This is undoubtedly a promising future for enterprises that have done a good job in technology R & D and business layout in advance# 01 the past and present life of precast buildings review the development process of precast buildings.

After the Tangshan earthquake in 1976, Yugoslavia presented the IMS system to China (i.e.

In recent years, the rising labor cost and the wide application of new technologies and materials have a profound impact on the development direction of the construction industry.

In 1851, the Crystal Palace, the venue of the London World Expo, made an amazing appearance, which was the first performance of factory precast components and on-site assembly in the history of modern architecture.

Thousands of years ago, the tenon and tenon structure widely used in Chinese traditional ancient buildings has been similar to today’s precast buildings.

In his book, he first put forward the concepts of standardized prefabrication, assembly and application premise of residential units, which laid a theoretical foundation for building industrialization and the development of precast buildings.

Nowadays, precast buildings are gradually improved in developed countries, and a complete set of precast building system has been formed, which has produced good economic benefits and market reputation, and promoted the further development of the global construction industry# Compared with foreign countries, China’s precast buildings started not late.