Whole process cost control of precast building based on BIM

Fig.

BIM Technology can also be used to determine the size of component and material databases for component information.

04 an example of precast construction cost control using BIM Technology analyzes an industrialized residential demonstration project in Shanghai.

Therefore, decision makers can make reasonable planning.

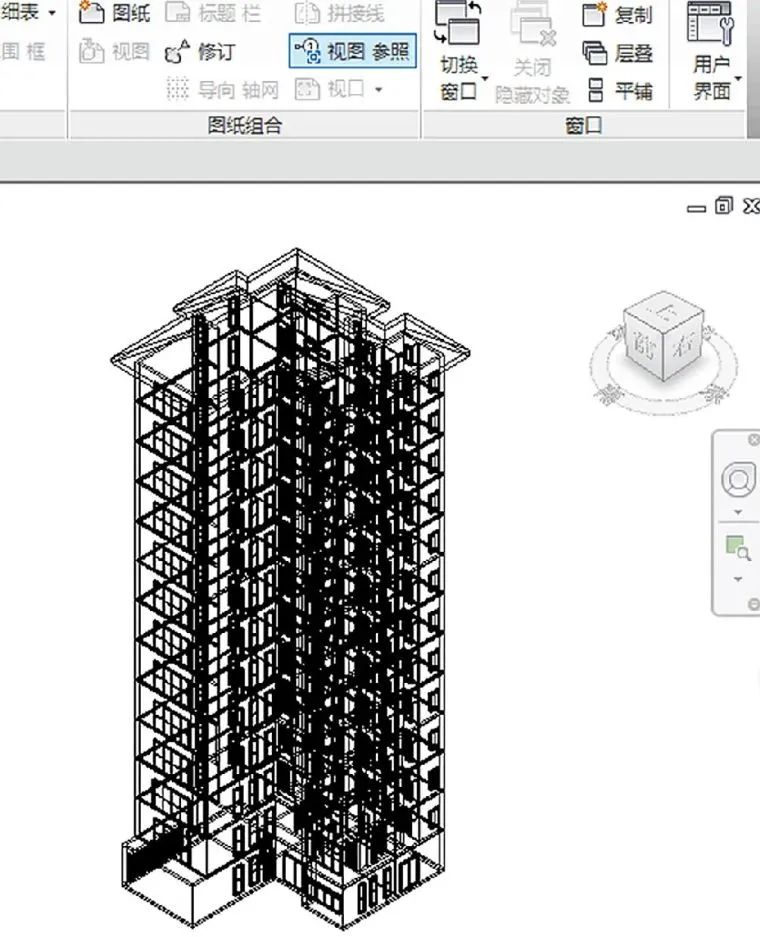

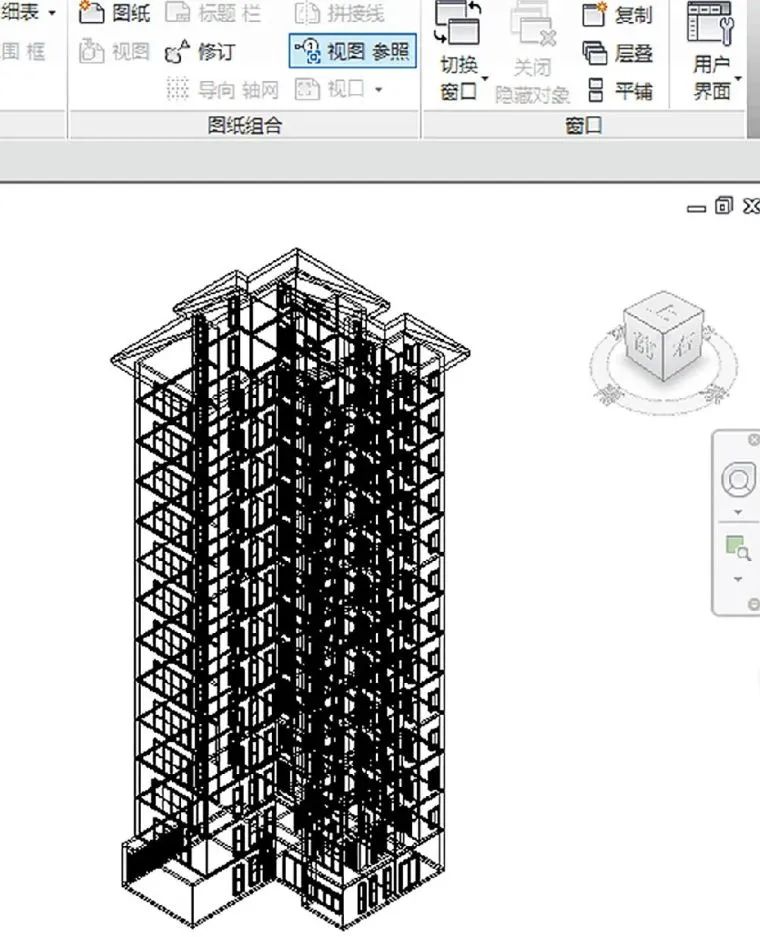

2 Schematic diagram of BIM building model cast building components are quite different from other products.

After the design is completed, the precast building needs to produce precast components in the factory, which is also a unique link of precast building.

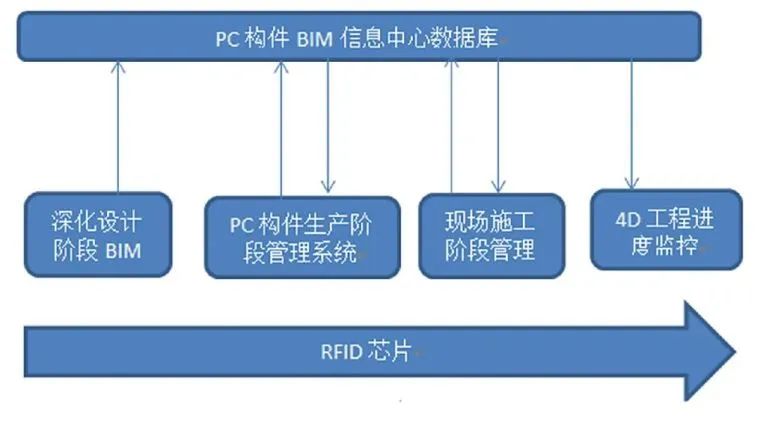

Figure 1 Schematic diagram of BIM application system the ability of extensible metadata attributes of BIM simulation objects is used as a means to store and potentially manage asset information and describe the structure of the represented building system and operation.

In addition, BIM Technology can be used to deal with changes in the construction process more conveniently.

This requires more strict requirements for the production process of the mold, so as to improve the universality, interchangeability and practicability of the mold, so as to ensure that the mold can be used many times in the production process, so as to prolong its life cycle and save the production cost.

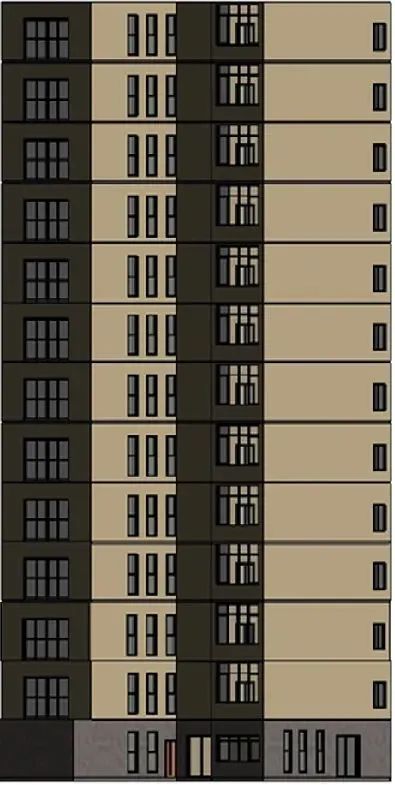

Figure 4 BIM building model in the initial stage of the project, BIM Technology is combined with geographic information system (GIS) to obtain field information and data, in which GIS technology is used for data analysis and BIM Technology is used for modeling.

When design changes occur in the construction process, BIM Technology can be used to associate the changes to the model, and reflect the changes in quantities and costs after the changes, so that decision makers can more clearly grasp the impact of changes on costs and adjust fund-raising and investment plans in time.

The project adopts BIM Technology for construction.

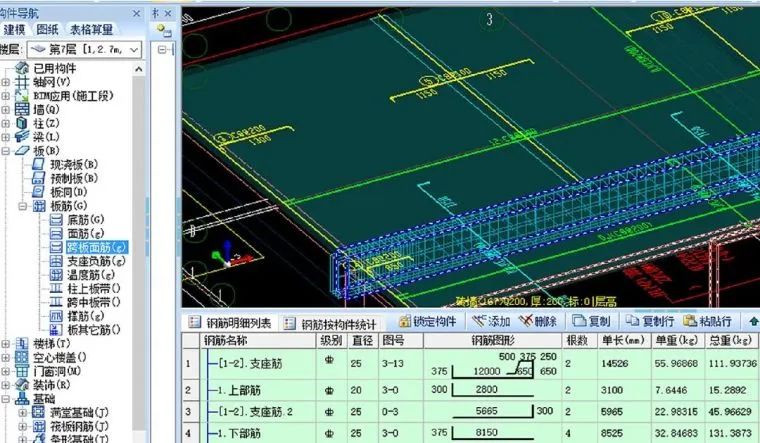

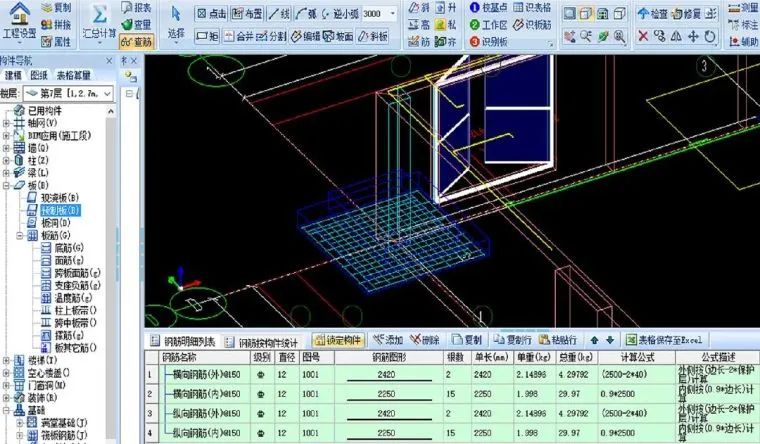

At the same time, because BIM modeling can provide complete quantities data, cost personnel can use BIM Technology to calculate in the cost budget stage, which can not only reduce the work intensity but also improve the cost accuracy.

03 cost control in the construction stage of precast buildings the cost control in the construction stage of precast buildings based on BIM Technology is a 5D model of BIM formed by adding time and cost to the 3D model, so as to carry out dynamic cost control.

The transition between design and cost management is the key period for users to be familiar with the new system, so as to improve the efficiency of construction operation management.

Since the design of the project starts after the approval of the project design and plan, the project design must implement all changes based on the original design, resulting in certain restrictions and difficulties in industrial design.

There are many kinds of cast building components, and the manufacturing process of each component is a complex collection of information.

It is required that the shape and size of the mold are absolutely accurate, and the error is large, which will seriously affect the follow-up work.

The structure and Mechatronics design are adopted to realize the control of the whole construction process.

In order to reduce the cost of precast buildings, BIM Technology is used to study the problems faced in the cost control of precast buildings.

3, it can be seen that the construction progress, cost plan and process logical relationship can be monitored in real time during the construction process, and the possible problems and risks in the construction process can be found in time, solutions can be put forward, and the construction schedule and resource and cost investment plan can be adjusted in real time.

Therefore, we can complete the cost control of the manufacturing stage of precast building components from the aspects of introducing BIM Technology, improving production technology and optimizing molds.

The schematic diagram of building model is shown in Figure 2.

Because it is difficult to accurately model complex high-performance features, and the efficiency and accuracy of optimization prediction are low, the possibility of cost difference will also increase.

Using BIM Technology to manage building information in the process of design and construction is a potential end use goal in the future.

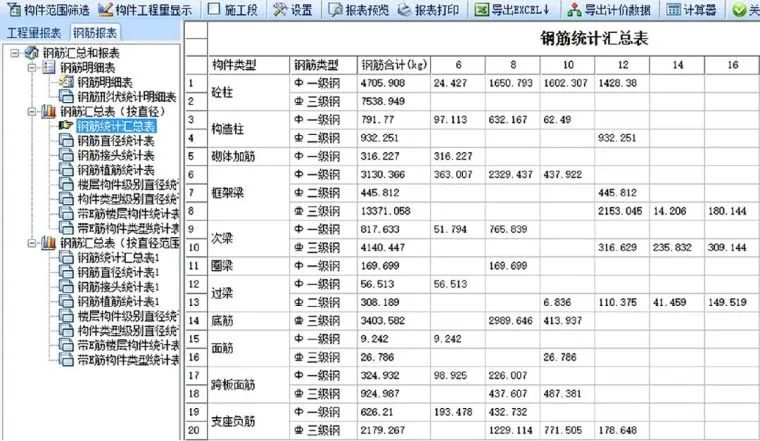

Figure 5 shows the summary overview of BIM Technology calculation..

The schematic diagram of BIM application system is shown in Figure 1.

Through the above methods, BIM Technology is used to manage the cost of precast buildings, promote the development of communication methods between BIM Technology and performance simulation tools, predict and analyze the cost control, use BIM as a platform to collect information, and implement the performance design and cost optimization of buildings.

01 construction cost control in the design stage of precast building construction.

02 the cost control in the production and manufacturing stage of precast building components is different from the traditional building method.

In the component design stage, the information stored in the BIM software system and the modeling interoperability function in the general design environment are used to reuse the supporting information to reduce data duplication.

Most examples of BIMS used to manage cost operations are simulations based on cost differences in the use of forecasts and the identification of deviations from forecasts.

Figure 3 shows the bill of quantities of BIM Technology.

As part of the BIM adoption process, the government has implemented mandatory and voluntary plans for these objectives, but further guidance is needed to improve Bim in the operation process in order to improve operational performance.

3 Schematic diagram of quantities from Fig.

Figure 4 shows the building model using BIM Technology.

BIM Technology is used to place information in the unit of components and links, combined with RFID technology, so as to manage the production, storage, transportation, hoisting and other processes of components.

Source: if there is infringement on the assembly engineering network, please contact the deletion.

Fig.

Through the all element dynamic monitoring and control technology of BIM Technology, the cast construction is monitored in real time, and the feasibility and efficiency of BIM Technology in known examples are compared, so as to obtain the balance point between resource allocation and construction efficiency, so as to minimize the construction cost and maximize the benefits of resource allocation.

Through the virtual modeling of BIM Technology, the material stacking, project progress and capital consumption can be simulated in the pre construction stage, which is conducive to understanding the possible problems in the construction process in advance, optimizing the construction sequence, optimizing the BIM model through reasonable resource allocation and guiding the implementation of construction.