Assembly process and installation steps of cast supports and hangers

The pipe support and lifting points of supports and hangers and the stress points of bearing structures shall be located in strict accordance with the design documents.

Fabricated supports and hangers shall be stored in a well ventilated and dry warehouse; Components with the same model and specification shall be stored on the shelf; When C-channel steel is stored, a moisture-proof film shall be laid on the ground, and dry wood strips (or wooden shelves, bamboo and boards, etc.) shall be padded on the moisture-proof film.

13.

The vertical installation angle of diagonal bracing of seismic hanger shall meet the requirements of design documents and shall not be less than 30 °; The distance between the diagonal brace of the single pipe seismic hanger and the hanger shall not exceed 100mm; The installation of diagonal bracing of seismic hanger shall not deviate from its centerline by 2.5 degrees.

12.

8.

3.

After the cast supports and hangers arrive at the site, they shall be subject to mobilization acceptance, and the supplier shall provide factory certificate and component and component test report.

7.

The overall installation spacing of cast supports and hangers shall meet the design requirements and the provisions of relevant current national standards, and the deviation shall not be greater than 0.2m.

Pipe clamp (adjustable) 11 Side cover; 12.

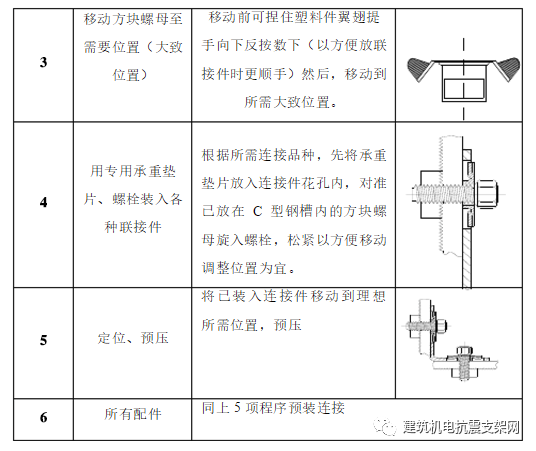

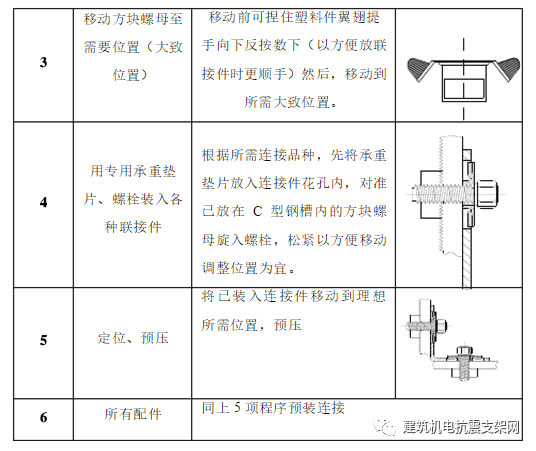

Fixings (or tiger clips) 13 Expansion bolt 4.2 principle of pre assembly connection sequence of support column – beam – column – base (fastener) – accessories and various system fasteners 05 inspection → torque wrench tool to tighten the bolt (the most important)! Adjust the torque to the specified torque with a torque wrench, tighten the locking auxiliary bolt at each joint point, and stop when the wrench slips for 2 times! The installation requirements are summarized as follows: 1.

14.

6.

Drawing identification → drawing list ● corresponding support number; ● clarify material requirements; ● fill in the blanking list; ● fill in and provide other materials; ● don’t omit, don’t be confused about blanking, and ask immediately if the drawing is unclear.

Gasket; 9.

For cast supports and hangers shared by two or more pipes, pipe clamps shall be used to keep the lateral relative position of the pipeline unchanged, and the thermal pipeline shall be able to slide freely along the axial direction.

Latch; 5.

17.

Pipe clamp (P type); 6.

18.

The cast supports and hangers fixed to the concrete structure shall adopt expanded bottom mechanical anchor bolts.

Connectors; 4.

The connection between the pipe clamp of the cast support and hanger and the uninsulated pipe shall be provided with anti vibration electrical insulation rubber pad; Electrochemical corrosion prevention measures shall be taken at the contact between stainless steel pipe and carbon steel support and hanger.

Boom; 8.

5.

15.

Before the installation of cast supports and hangers, it is necessary to check whether the model, specification and materials of the installed supports and hangers comply with the provisions of the design documents.

10.

Pipe support; 7.

Pipe supports and hangers should be in place before the installation of the pipes they support.

The material, specification and performance of cast supports and hangers shall meet the requirements of design documents and relevant current national standards.

The size of the pipe clamp shall match the outer diameter of the pipe or the outer diameter of the insulation layer, and the part connected with other connecting parts of the support and hanger shall be exposed outside the insulation layer of the pipe, and the connection between the pipe clamp and the pipe shall be stable.

Bolts and nuts shall be locked according to the design torque to prevent loosening.

The surface of the base material in the anchorage area shall be solid and flat, and there shall be no defects affecting the anchorage bearing capacity, such as sanding, shelling, honeycomb, pitted surface, oil stain and so on; Within the range of anchorage depth, the concrete strength grade shall reach C30 or above; Anchor bolt drilling shall comply with the provisions of relevant codes and regulations; The anchoring operation shall meet the design requirements of anchor bolt.

Fabricated supports and hangers shared by two or more pipes shall not be used to support horizontal pipes with different thermal displacement or thermal displacement direction..

The positioning deviation of the pipe support and lifting point relative to the indoor pipe shall not exceed 10mm; The supports and hangers shall be fixed on the reliable building structure without affecting the structural safety.

Base; 3.

The fully exposed channel steel notch end shall be installed with channel steel end cover except for those that will form ponding.

Before the installation of cast supports and hangers, the construction unit shall clarify the construction scope, and the installation personnel shall coordinate the installation of all pipelines in the area with other disciplines, formulate a reasonable installation sequence, so that the main components and pipelines close to the bearing structure shall be installed first.

2.

Nut; 10.

04 assembly → various wrench tools and spare parts 4.1 introduction to spare parts 1 Column (or beam); 2.

03 punching → hydraulic punching machine ● people need to be trained and guided by professional hydraulic punching operation; ● check whether the electrical, oil supply system and leakage protection appliances are sensitive and reliable before use; ● the operation shall be carried out in accordance with the equipment operation instructions; ● pay attention to the connection of oil circuit connector and oil pipe protection; ● after the work is completed, the site shall be cleared, the switch shall be turned off, and the switch cabinet shall be locked.

The perpendicularity of the section shall be ensured when cutting C-channel steel and through screw on site; When cutting C-channel steel, the opening shall face down, and deformation shall be avoided during cutting; The burr at the cutting end shall be polished smooth, and the adsorbed iron filings and powder shall be removed in time and wiped clean.

Except that C-shaped channel steel and through screw can be cut on site, the components and profiles of all other products shall be precast in the factory and assembled on site.

9.

11.

02 material preparation and sawing → sawing machine ● personnel shall be trained and guided by professional sawing machine cutting operation; ● before use, check whether the electrical, equipment grounding, leakage protection appliances are sensitive and reliable, and whether the safety protection device is intact; ● use positioning device, and measure and compare after adjustment; ● when cutting, pay attention to cutting and take materials in time to prevent the saw blade from rotating and driving materials and flying out to hurt people; ● stack neatly as required; ● the safety protective cover cannot be disassembled, and the maintenance, refueling and cleaning during mechanical operation are not allowed; ● clean the site after work, switch off the power and lock the switch cabinet.

C-channel steel of different models shall be stacked separately; Dry wood strips shall be padded between unsealed C-channel steel; The stacking height shall be in accordance with relevant regulations, and anti overturning measures and warning signs shall be provided.

Fabricated supports and hangers shall have measures to adjust the vertical height of the pipeline, and the vertical height of the pipeline shall be directly adjusted under the bearing conditions.

4.

16.