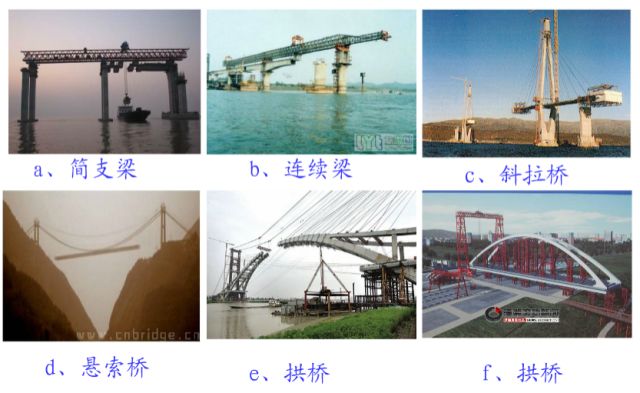

Precast bridge construction, from pier and abutment to cable tower, all completed!

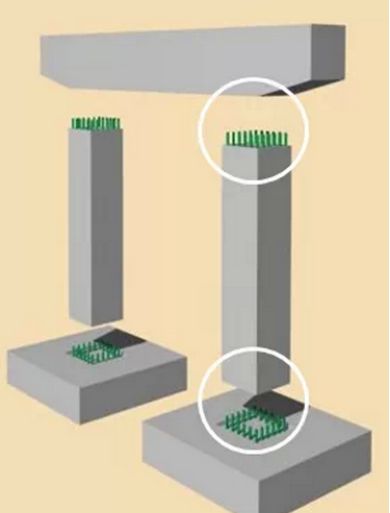

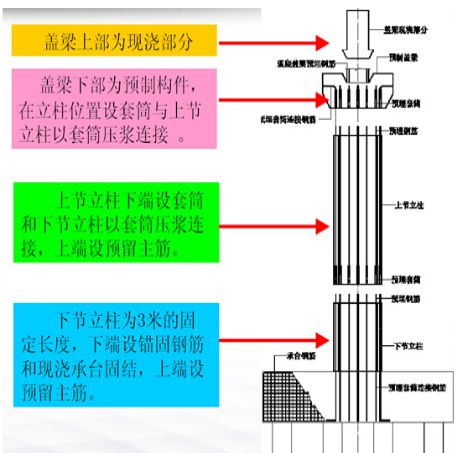

The precast pier body connects the reinforcement protruding from the pier body through the grouting metal corrugated pipe embedded in cap beam or cap beam.

The bonded prestressed tendon connected precast assembly pier has similar deformation capacity as the cast-in-situ concrete pier, but its energy dissipation capacity is weak..

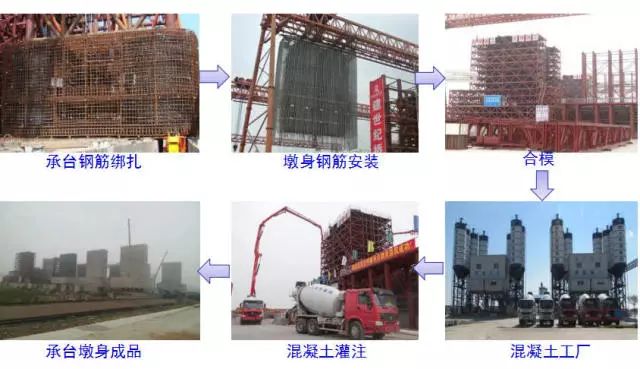

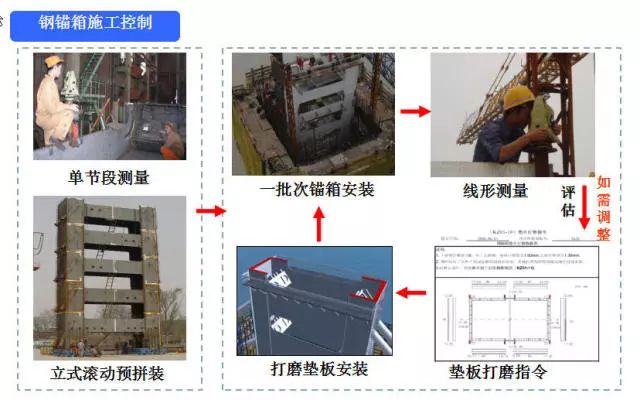

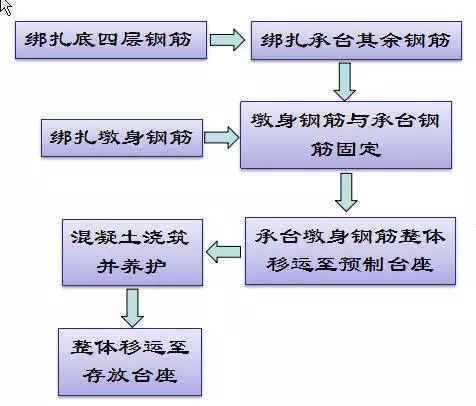

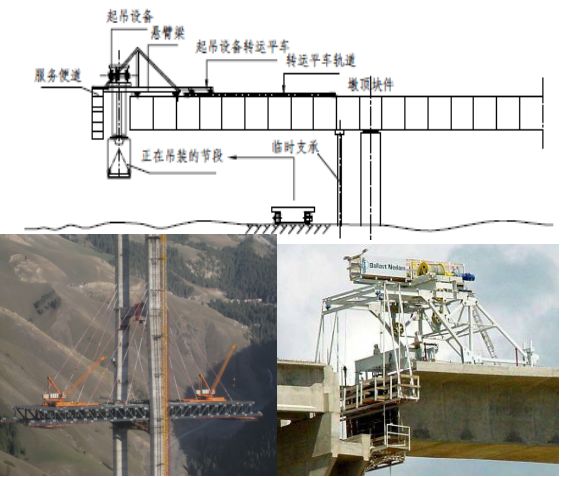

The construction process mainly includes precast components, installation and connection and concrete joint filling.

This structure is characterized by that the prestressed reinforcement passes through the joint, which is widely used in practical engineering, and the design theory and calculation are divided into two parts Analysis and mature construction technology experience.

Temporary support shall be set, and the connection part of reinforcement shall be through post cast concrete (wet joint) connection, which is also the design idea of segmental assembled pier widely used in China.

Common assembly joints are as follows: (1) The bonded post tensioned prestressed reinforcement connection structure is adopted.

The contact surface between the pier body and the bent cap or bearing platform often adopts the mortar cushion, and the epoxy adhesive joint structure is used between the pier body sections.

Compared with grouting sleeve and metal bellows, it has the advantage that the required construction tolerance can be larger, and a certain amount of concrete needs to be poured on site.

Seismic performance of precast assembled columns the seismic performance of precast columns is a technical problem that hinders the application of full precast assembly technology in bridges in high seismic risk areas.

At the same time, the on-site construction requires tensioning and grouting of the prestressed reinforcement.

A certain thickness of mortar is laid at the bottom and filled with semi-dry concrete around.

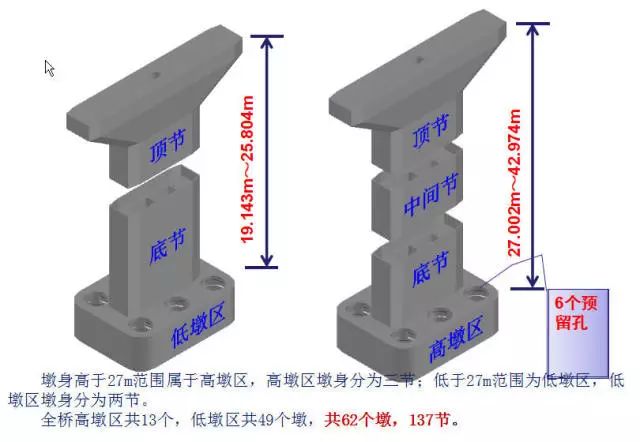

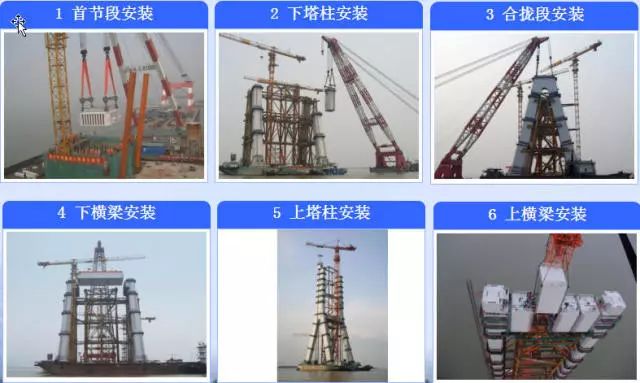

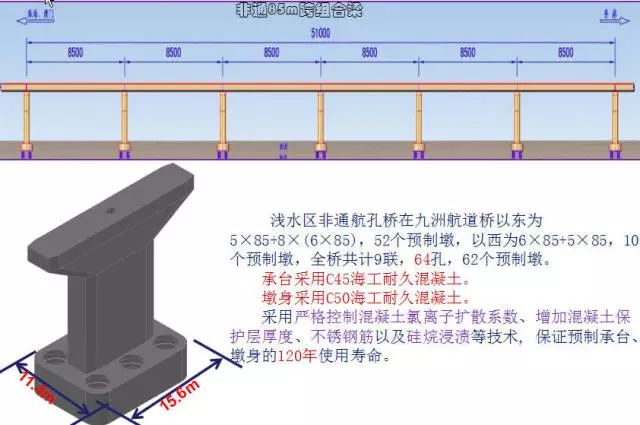

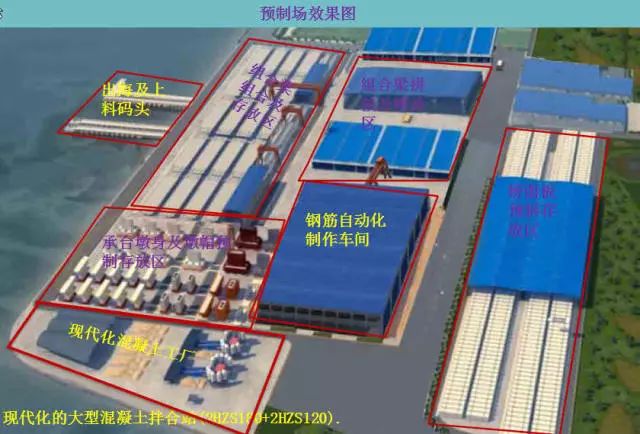

The main characteristics of cast piers and abutments are that they can be precast in the Prefabrication Yard and are less disturbed by the surrounding environment, but relatively speaking, they have high requirements for transportation and hoisting machinery and equipment.

Beijing Jishuitan bridge in China is built with this connection structure, and some bridges in the United States are also built with this connection structure.

(5) The reinforcement shall be welded or overlapped and precast and assembled with wet joints.

Its seismic performance is still under study.

The insertion length is generally 1.2 ~ 1.5 times of the section size of the pier body.

At present, a few bridges abroad have used this connection structure for construction, and it is rarely used in high earthquake risk areas.

From the application experience abroad, low seismic risk areas have been widely used, and the application and scientific research of high seismic risk areas are still in progress.

The advantages are simple construction process and less on-site operation; the disadvantages are the mechanical behavior of the joint, especially the seismic performance How to do this needs further research.

The test results show that compared with the traditional cast-in-situ concrete pier, the pier with sleeve and bellows precast assembly connection structure has similar seismic performance and can meet the requirements of expected seismic performance.

Taking the typical actual engineering pier structure as the prototype, Select the sleeve and bellows (duct) and bonded prestressed tendons, the low cycle repeated horizontal loading scale test of rectangular solid segmental precast columns is carried out.

The cast column pier system decomposes the pier into several components, such as bearing platform, column, bent cap (pier cap), etc., which are precast in the factory or on site, and then transported to the site for assembly into bridge pier.

The prestressed reinforcement in the scheme can adopt high-strength reinforcement such as steel strand or finish rolled deformed steel bar.

The disadvantage is that the cost of the pier body is much higher than that of the traditional cast-in-situ concrete pier.

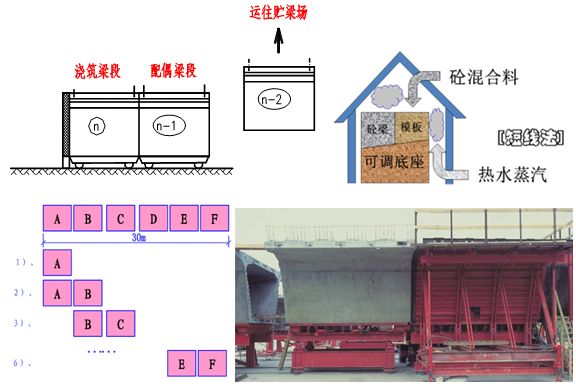

Don’t you hurry to learn it? 1、 Precast pier and abutment construction precast pier and abutment is to divide the tall pier and abutment into several components vertically, according to a certain modulus and horizontally, pour on the Prefabrication Yard around the bridge site, transport it to the site by vehicles and ships, and hoist and assemble it.

In order to realize the comprehensive popularization and application of full precast assembly technology, it is necessary to carry out in-depth research on the seismic performance of precast assembled columns.

With the development of external prestressing technology and the corrosion of internal prestressing tendons, the precast construction method is becoming more and more popular in China.

Through the quasi-static test and finite element numerical analysis of segmental precast column specimens under different structural details, the hysteretic characteristics, ductile deformation and non-linear deformation at joints of segmental precast columns under different structural modes are studied Linear mechanical behavior, damage and failure mechanism, etc.

Source: the copyright of Zhulong forum belongs to the original author.

The structural characteristics are that the construction accuracy requirements are high, the time required for on-site construction is short, and there is no need to tension the prestressed reinforcement, and the on-site workload is significantly reduced, Its mechanical properties under normal service conditions are similar to those of traditional cast-in-situ concrete piers, so it has certain economic advantages.

(6) Socket connection socket joint connection structure is to insert the precast pier body into the reserved hole corresponding to the foundation.

(2) The grouting sleeve is used to connect the precast pier body sections, and the protruding reinforcement is connected through the grouting connecting sleeve.

A certain number of reinforcement shall be extended in advance for the pier to overlap with the reserved reinforcement of adjacent components.

The bonded post tensioned prestressed reinforcement connection structure often cooperates with the mortar cushion or epoxy adhesive joint structure to realize the construction of segmental Precast Pier.

The construction process is complex and the construction time is long.

Mortar cushion is often used on the contact surface between pier body and cap beam or cap, and epoxy adhesive joint structure is used between pier body sections, as shown in Figure 5 The construction time on the construction site is short, but it needs to meet the sufficient anchorage length of longitudinal reinforcement, and its mechanical properties are similar to those of traditional cast-in-situ concrete piers.

It is mainly used for the connection between pier body and bent cap, pile and bearing platform.

The assembly joint is the key process, which should be firm, safe, simple and convenient for construction.

As shown in the figure.

(4) Slot connection slot connection structure is shown in Figure 6, which has been applied in some bridge projects.

The mechanical properties of pier constructed with this structure are often similar to those of traditional cast-in-situ concrete pier, but the existence of wet joint will increase the construction time and the amount of on-site reinforcement lapping and pouring.

(3) Grouting metal corrugated pipe connection this connection structure is commonly used for the connection between pier body and cap or between pier body and cap beam.

From the perspective of rapid construction, this scheme has some deficiencies.