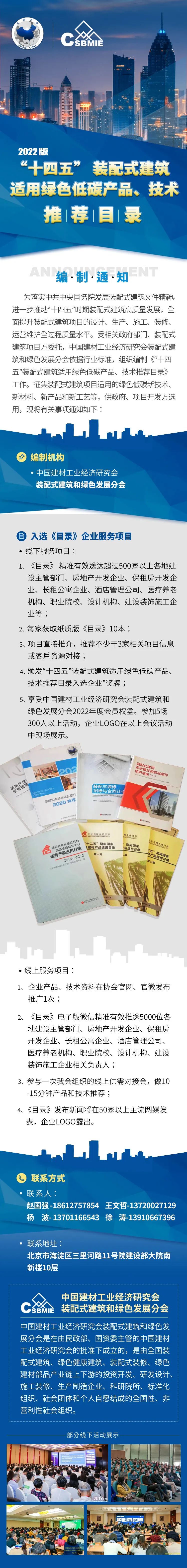

Precast buildings are continuously online and accurately enable the industrialization of new buildings

First, formulate national mandatory low-carbon building standards and clearly define low-carbon housing; Second, increase low-carbon requirements in land supply and increase the supply of low-carbon housing in the market; Third, with reference to a series of policies such as the encouragement of low-energy household appliances, cash subsidies or deed tax reductions will be given to individuals who purchase standard low-carbon houses.

Continuous on-line assembly enables building industrialization.

Whether at the national, market, industry or user level, there are higher requirements and standards for construction industrialization.

Under the call of the highest decision-making level of the country to ‘develop precast buildings and promote the industrialization of new buildings’, local governments have also responded to the call to actively plan policies related to precast interior decoration.

The realization of new building industrialization is of great significance to change the current situation of China’s construction industry and promote the sustainable development of the construction industry: it is conducive to improving the technical level and management level of the construction industry; It is conducive to improving the efficiency of Engineering Construction: it is conducive to reducing the consumption of resources and energy during the construction and use of construction products, reducing environmental pollution, and realizing the sustainable development of economic, social and environmental benefits; It is conducive to improving the quality and safety of construction projects: it is conducive to improving the quality of construction products; It is conducive to improving the quality of employees and working conditions, and solving the problem of labor shortage in the construction market; It is conducive to promoting the reform of project construction management system.

With fewer and fewer traditional craft practitioners and less and less non renewable material resources, it is urgent for the construction industry to change its inherent decoration mode.

Most provinces have followed the policy guidance of the Ministry of housing and urban rural development on precast decoration, that is, to promote the application of precast decoration in commercial housing projects, promote pipeline separation and integrated decoration technology, promote integrated modular building components, improve decoration quality and reduce operation and maintenance costs..

The development of precast new buildings promotes the standardization, generalization, informatization and integration of precast buildings, helps the innovative development of the whole industrial chain of precast buildings, and promotes the industrialization of new buildings to a higher level.

Facing the problems existing in the development of new building industrialization, such as the lack of policy support; Imperfect technical standards: inadequate industrial management measures, etc.

While the energy consumption of the construction industry is high, the traditional building energy-saving technology also has certain potential safety hazards.

Vigorously promote low-carbon housing.

Facing the huge market demand, industrialization has become a way to maximize the efficiency of decoration and reduce costs.

With the introduction of precast schemes in various provinces and cities, many real estate and decoration enterprises attach great importance to the policy preference, and devote all their efforts to promoting the development of “precast”.

In view of the industrialization trend of building development, we should vigorously promote precast buildings and constantly improve the standardization and technical level of precast buildings.

We will speed up the cultivation of professional talents, and all kinds of talents will work with certificates.

For example, the external thermal insulation material of the external wall falls and injures people occasionally; Some thermal insulation materials did not use fire-retardant technology, causing fire accidents, etc.

Continue to increase the research on new materials and new processes, and eliminate the current common quality problems.

At present, in the specific implementation opinions of new building industrialization formulated by various provinces, precast decoration has become an important part of the implementation opinions.

If building materials are added, it is expected to be about 40%, that is to say, about 1/3 of China’s energy is consumed in the construction industry.

Big labor believes that the development of precast buildings is the main measure of green development and low-carbon circular development in the field of urban and rural construction.

Improve the existing domestic atlas and construction operation manual, and add treatment measures for common quality problems.

The traditional construction industry has serious pollution problems, and it is imperative to complete the construction industrialization.

It is not only an important means to stabilize growth, promote reform and adjust structure, but also the internal requirement of building a “double engine” of economic development.

In recent years, precast buildings have received great attention from all walks of life.

The assembly type full decoration also has many advantages for comprehensively improving the housing quality, effectively improving the safety, durability, comfort and environmental protection of the building, and meeting the people’s higher demand for construction quality and the yearning for a better living life.

Promoting building energy conservation and emission reduction and adopting new technologies and materials will help China achieve the goal of carbon neutrality as soon as possible and eliminate potential safety hazards at the same time.

One of the ways to realize industrialization is to develop assembly technology.

The data shows that the direct energy consumption of buildings in China has increased from 10% in the late 1970s to 30% this year.

In addition to the consumption of building materials, at present, the vast majority of buildings still use the traditional cement mortar construction method, which not only has a long construction period, but also consumes a lot of manpower, and the environmental pollution is also quite serious.

In the context of industry 4.0, the road of building industrialization gradually takes the assembly type as the main path.

As early as December 10, 2012, the relevant departments issued the “opinions on promoting the industrialization of new buildings”.

The “opinions” require the in-depth implementation of the scientific concept of development, focusing on accelerating the transformation of economic development mode, taking the road of new industrialization of the construction industry, focusing on improving the integrated innovation ability of the construction industry, improving the modernization level of the construction industry as a whole, forming a technology-oriented, reasonable industrial structure, and high level of professional and mechanized construction, Efficient, energy-saving and environment-friendly industrial clusters with independent intellectual property rights and core competitive advantages promote the coordinated development of economy, society, resources and environment.

The future development of the construction industry will mainly focus on the realization of industrialization.

And put forward the main tasks and policy measures to promote the industrialization of new buildings.

The mandatory use of steel structures in high-rise buildings effectively improves the degree of industrialization and enhances structural safety.

It is understood that precast buildings can reduce at least 50% of the on-site construction time, and the erection site is basically free of dust and construction waste, minimizing the environmental problems caused by traditional construction methods; In addition, due to the technical convenience brought by digitalization, the collaboration speed and efficiency in all aspects have been greatly improved.