A comprehensive analysis of the key points of structural design of precast houses

However, there are differences in the range of components included in the calculation of prefabrication rate (assembly rate) and the conversion proportion of prefabrication rate (assembly rate) of various components.

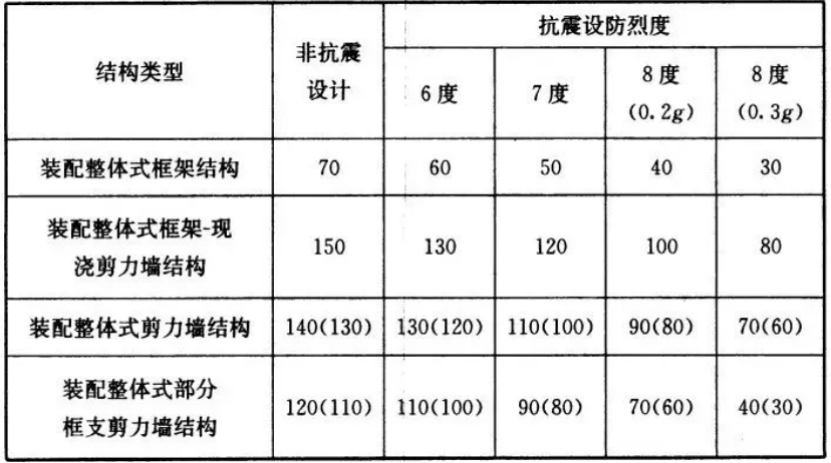

One is the building height.

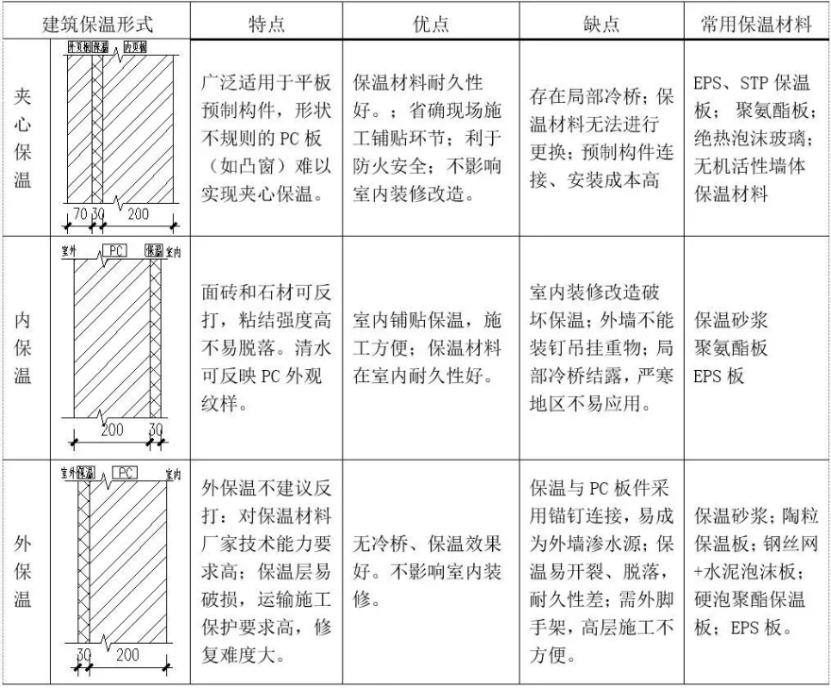

The characteristics of various thermal insulation forms and materials shall be considered in the design.

In recent years, the fourth design institute has participated in the design of a number of precast houses, obtained extensive market recognition and accumulated some design experience.

The common cast structural systems include fully precast shear wall bearing system, precast shear wall exterior wall formwork system, precast double-sided laminated shear wall system, etc.

Click “made in China 2025” to pay attention to us / / it is the first ten-year action program for the Chinese government to implement the manufacturing power strategy.

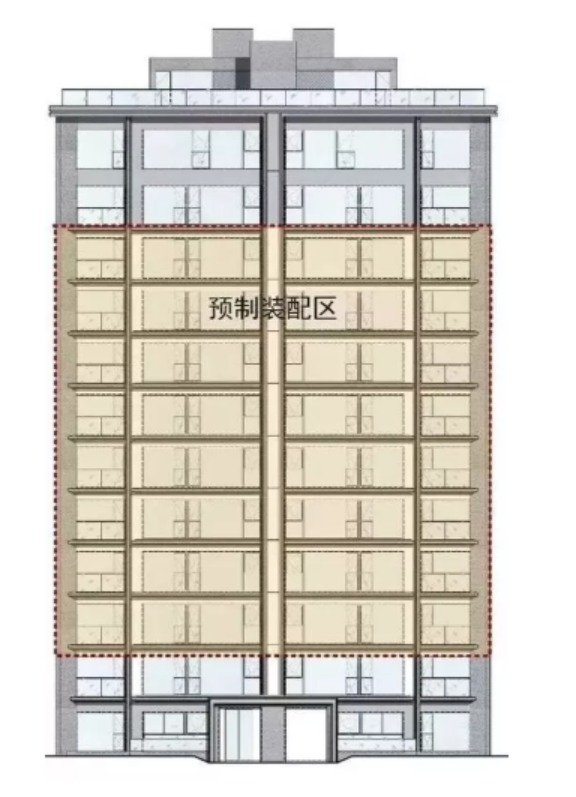

Maximum applicable height of precast integrated structure house (m) common insulation forms and characteristics PC special design contents and key points in each stage scheme stage: PC special design in scheme stage mainly includes the following contents: (1) determine the area ratio and prefabrication rate of precast buildings according to local policies and owner’s requirements (2) select precast structure system (3) determine the type and floor range of precast components.

The common forms of thermal insulation include sandwich thermal insulation, internal thermal insulation and external thermal insulation.

Taking the detailed rules for calculation of prefabrication rate and assembly rate in Shanghai as an example, prefabrication rate refers to the ratio of the material consumption of precast components in the main structure and enclosure structure of precast buildings of concrete structure, steel structure, steel-concrete mixed structure, wood structure and other structural types to the total material consumption of corresponding components.

“Others” refers to the integration of structure and thermal insulation, the integration of wall and window frame, integrated wall, integrated floor and combined reinforced products.

3.

Assembly rate refers to the ratio of the quantity (or area) of precast components and building parts to the total quantity (or area) of similar components or parts in precast buildings.

Precast structure system and characteristics precast structure system and characteristics precast shear wall external wall formwork system precast double-sided superimposed shear wall system there are two main factors restricting the precast structure system.

Method 1 is only used for concrete structures, and method 2 can be used for concrete structures, steel structures and wood structures.

The representative processes, advantages and disadvantages of each system are shown in the figure below.

The precast house with concrete structure can be calculated by two methods.

Single building assembly rate = single building prefabrication rate + part assembly rate + other part assembly rate = ∑ (part weight) × Proportion of parts) × 100% of which, “part” refers to precast internal partition wall, unit curtain wall, integrated kitchen, integrated toilet, integrated pipe well and integrated smoke exhaust duct.

Non concrete precast components such as curtain wall, stone and gypsum board are not included in the prefabrication rate, and the infilled wall of interior wall is not included in the prefabrication rate.

Among them, When determining the type of precast components, it should be noted that the reinforced area at the bottom of shear wall structure should not be precast, the transfer beam and frame pillar of frame supported structure should be cast-in-situ, and the elevator shaft of high-rise should be cast-in-situ structure.

The second is the form of building thermal insulation.

The specification lists two calculation methods: calculation method 1: prefabrication rate = volume of precast concrete components / (volume of precast concrete components + volume of cast-in-situ concrete) calculation method 2: prefabrication rate = ∑ (component weight) × correction factor × Precast elements (scale) × The following points shall be noted during 100% calculation: 1 The calculation range in Shanghai is above the outdoor floor, and each single building is taken as the calculation unit.

The scope of precast components in Shanghai only includes the main structure and exterior wall enclosure structure.

2.

Prefabrication rate and assembly rate at present, in addition to the unified provisions on the assembly rate in the national standard evaluation standard for precast buildings, Shanghai, Jiangsu, Beijing, Chengdu, Shenzhen, Hunan, Hubei and other provinces and cities have also successively issued detailed rules for the calculation of local prefabrication rate and assembly rate.

In the selection of precast floors, the cast-in-situ floor structure should be adopted for the basement floor and roof floor of the house; For floors and structural transfer floors with large openings, cast-in-situ floor structure shall be adopted..

Today, let’s share some experience in the structural design of precast houses.

According to the provisions of the existing specifications, the assembled integral houses with different structure systems have the maximum applicable height limit.

Under the background of industrialized construction and a new round of scientific and technological revolution and industrial reform of “made in China 2025”, China’s construction industry has ushered in new changes and significant impact, especially precast housing, which has been widely practiced everywhere.