How to do the construction quality management and acceptance of precast buildings?

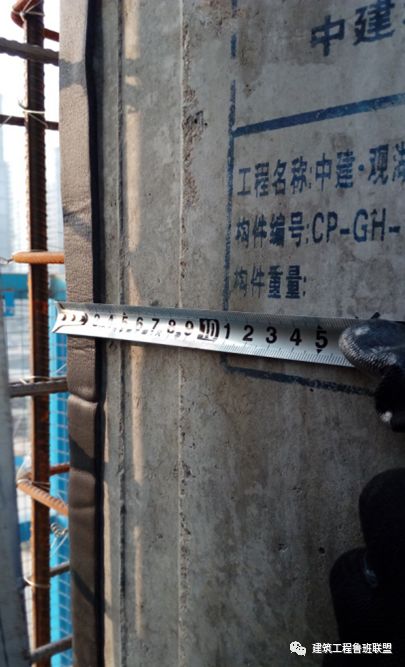

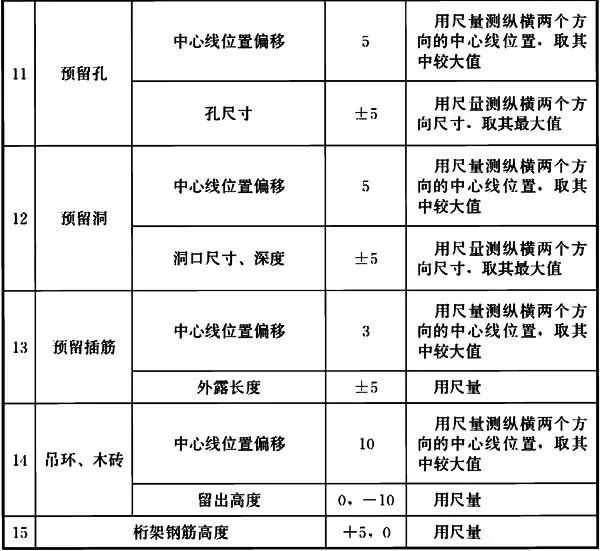

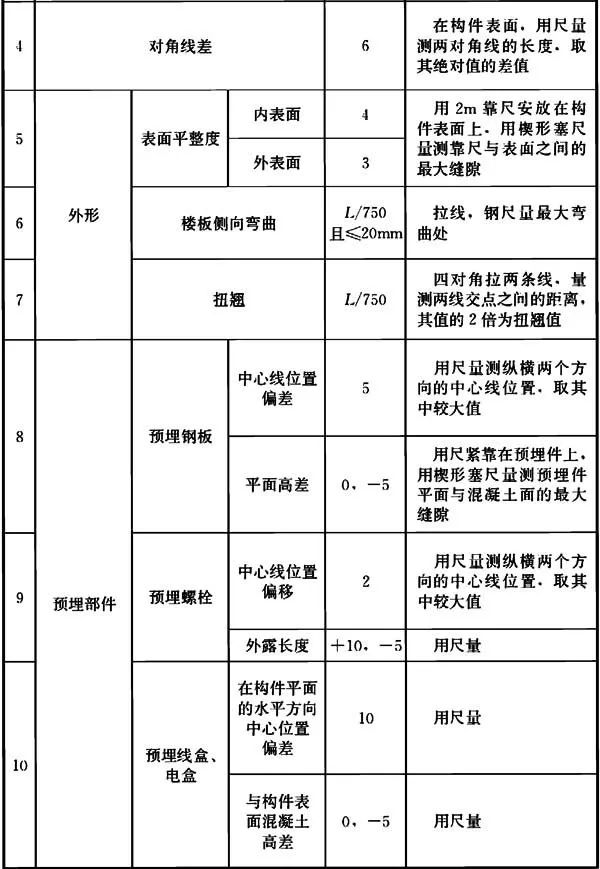

All the components entering the site shall be submitted with relevant production data, and the appearance, size, reservation and embedment shall be comprehensively inspected.

Fabricated buildings have become a hot national policy.

Other sub divisional works in the concrete structure sub divisional works shall comply with the relevant provisions of the current national standard Code for Acceptance of Constructional Quality of Concrete Structure Works GB50204.

Grouting can be carried out only after the acceptance is qualified.

Inspection method: check quality certificates or quality acceptance records..

4 Raw materials, components, components and fittings used in the construction of precast concrete structures shall be accepted on site according to the inspection lot.

Before commercial concrete pouring, check the data of commercial concrete attached to the vehicle, report to the supervisor for acceptance and sign the concrete pouring order before pouring.

2 Quality management requires strict implementation of the “three inspections” system in the construction: after each process is completed, it must pass the self inspection, mutual inspection and handover inspection of the team, and the professional quality inspector shall recheck, improve the corresponding data, and report to the supervision engineer for inspection and acceptance before the next process can be carried out.

Based on the engineering practice of China Construction Seventh Engineering Bureau, this paper summarizes the construction quality management and acceptance practices of precast concrete buildings for reference.

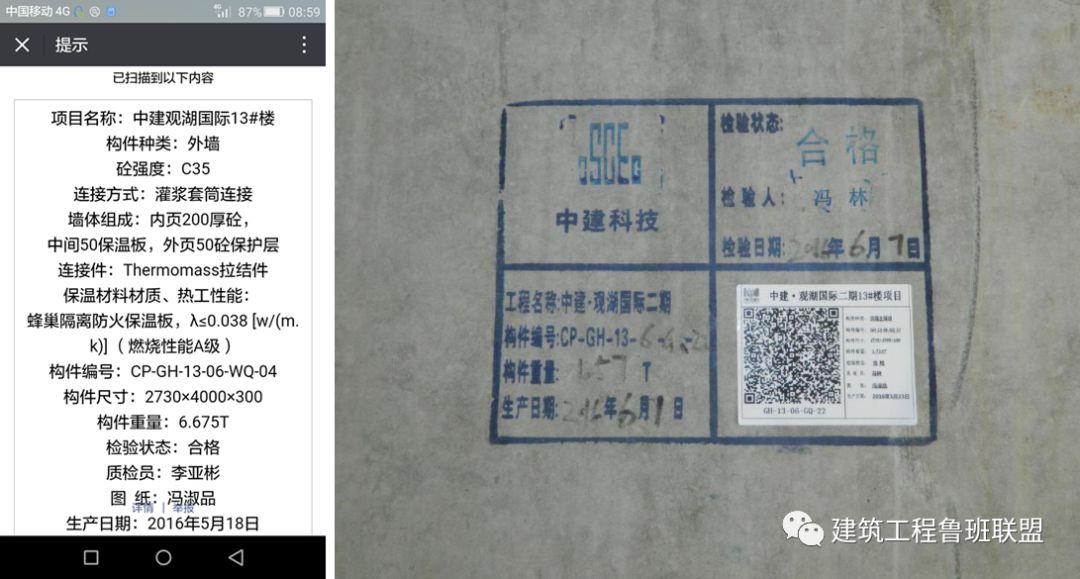

Precast components produced by professional enterprises shall be inspected for quality certificates when entering the site.

Before the construction of precast concrete buildings, it is advisable to select representative units for trial installation of precast components, and timely adjust the construction process and improve the construction scheme according to the trial installation results.

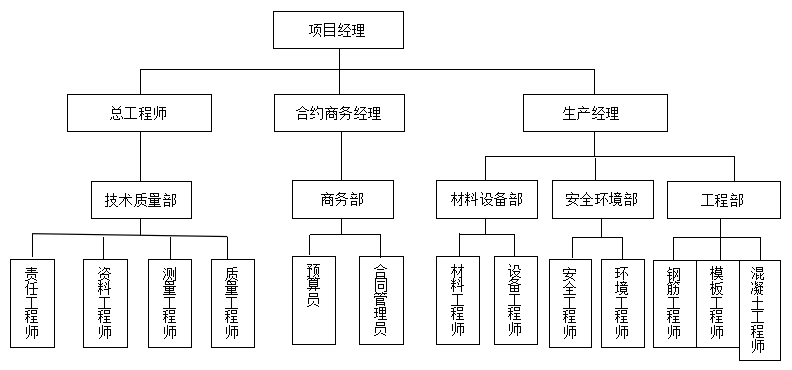

Allocate corresponding quality management personnel and earnestly implement various quality management systems, regulations and relevant specifications.

The construction unit and the supervision unit shall formulate strict quality supervision and management measures, organize regular supervision meetings, coordinate work arrangements, review project progress, report the quality and safety hazards of the project, and urge the construction unit to rectify.

The precast components shall be transported by reliable transport vehicles and special storage racks during the mobilization acceptance.

2 The decoration, mechanical and electrical installation and other divisional works of precast concrete buildings shall be subject to quality acceptance according to the current national standards.

Before sleeve grouting, the installation quality of components shall be reported to the supervisor for acceptance.

The construction process shall strictly control the on-site production process of grouting materials, assign special personnel to supervise the grouting process, ensure the quality of grouting operations, and make grouting records.

4 Hoisting requires that the precast concrete building construction should adopt a tooled and standardized tooling system.

All components shall be subject to quality acceptance before mobilization, and can only be used after they are qualified.

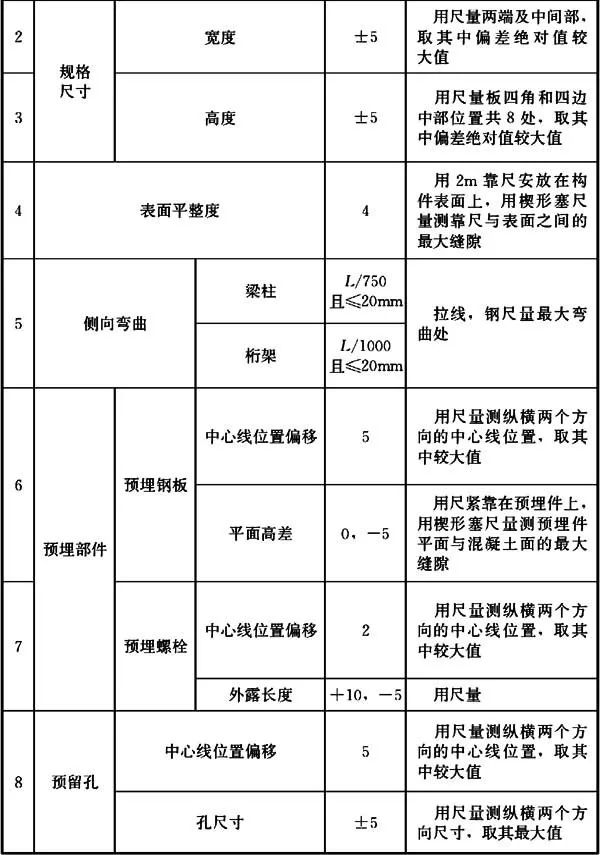

Grouting material inspection Grouting material test block retention After grouting operation is completed Plugging 6 Process quality control and inspection Wall installation quality inspection Cast in situ node inspection Wall positioning line inspection 7 Supervisor acceptance Wall installation quality acceptance Concealed work quality acceptance [Appendix] Provisions for quality acceptance of precast concrete buildings – General provisions 1 Construction of precast concrete buildings shall be in accordance with the current national standard Unified Standard for Construction Quality Acceptance of Building Engineering Division and quality acceptance of unit works, divisional works, subdivisional works and inspection lots shall be carried out according to relevant provisions of GB50300.

6 During the acceptance of concrete structure subprojects, in addition to providing documents and records in accordance with the relevant provisions of the current national standard Code for Acceptance of Construction Quality of Concrete Structures (GB50204), the following documents and records shall also be provided: (1) engineering design documents, installation and construction drawings of precast components and detailed processing and fabrication drawings; (2) Quality certificates, site acceptance records and sampling re inspection reports of precast components, main materials and accessories; (3) Installation and construction records of precast components; (4) Type inspection report, process inspection report and construction inspection record of reinforcement sleeve grouting, and construction inspection record of mortar anchor overlapping connection; (5) Inspection and acceptance documents for concealed works at post cast concrete parts; (6) Test report on strength of post cast concrete, grouting materials and grouting materials; (7) External wall waterproof construction quality inspection records; (8) Quality acceptance documents of precast structure subdivisional works; (9) Handling plan and acceptance record of major quality problems of cast engineering; (10) Other documents and records of cast engineering.

3.

Inspection quantity: full inspection.

1 Quality management system The construction unit shall establish a sound and reliable technical quality assurance system.

II.

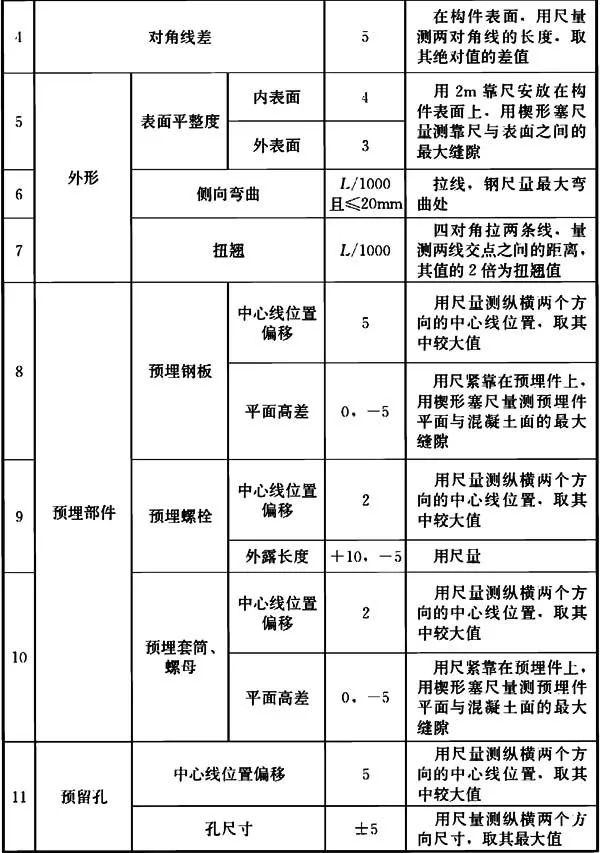

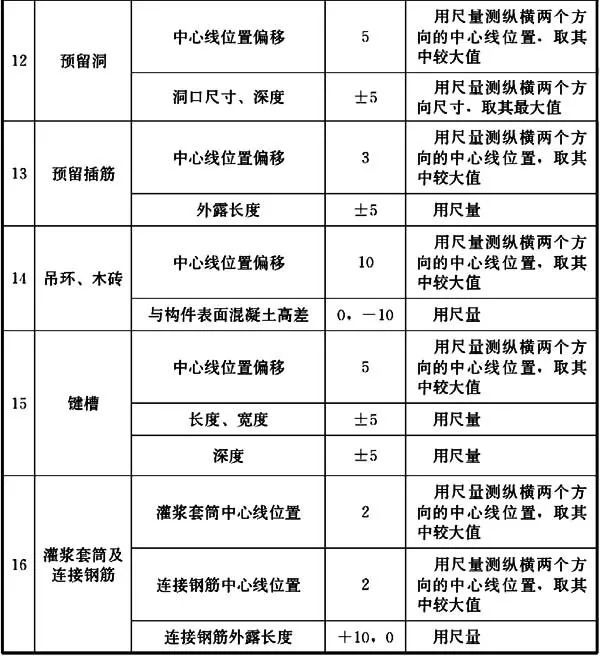

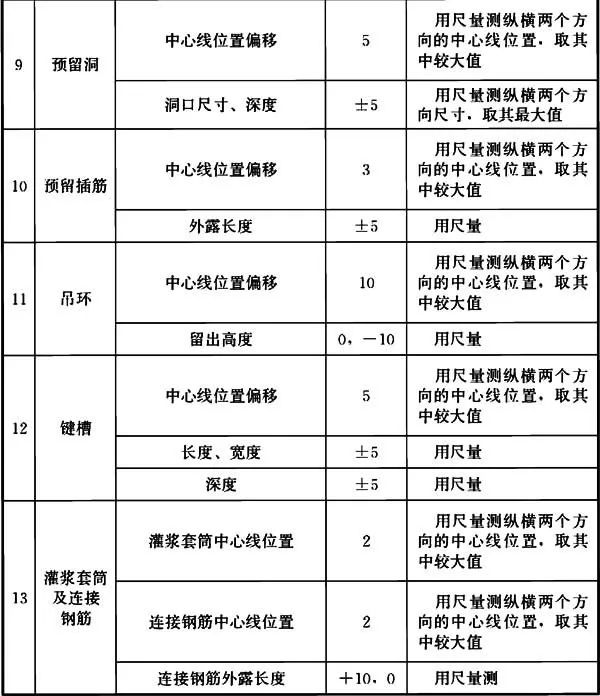

Precast components mainly controlled by project 1.

3 The precast concrete structure works shall be accepted as the concrete structure sub divisional works, and the precast concrete structure shall be accepted as the concrete structure sub divisional works.

The whole process of grouting shall be supervised and grouting records shall be made.

5 Concealed works acceptance shall be carried out before pouring concrete for connection nodes and composite members of precast concrete structures.

However, for precast buildings, most projects lack theory and experience, and there are still many problems in on-site construction quality management and acceptance.

The acceptance of concealed works shall include the following main contents: (1) the quality of concrete rough surface, the size, quantity and location of keyways; (2) Grade, specification, quantity, position and spacing of reinforcement, bending angle of stirrup hook and length of straight section; (3) Connection mode, joint position, number of joints, percentage of joint area, overlapping length, anchorage mode and anchorage length of reinforcement; (4) Specification, quantity and position of embedded parts and reserved pipelines; (5) Waterproof and fireproof construction practices at the joints of precast concrete components; (6) Thermal insulation and node construction; (7) Other concealed items.