Effect of Grouting Defects on Seismic Behavior of Fabricated Concrete Columns

Each level shall be loaded step by step in an increment of 5mm, and the specimen shall be cycled twice at each level until the member fails or the horizontal load drops below 85% of the ultimate load.

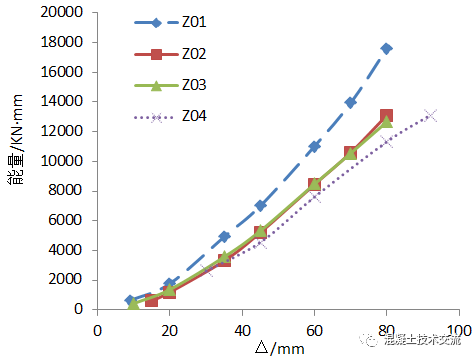

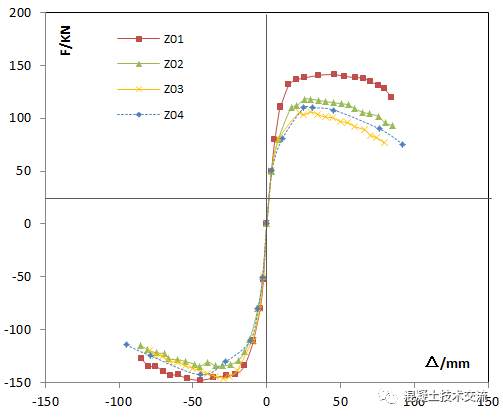

Fig.

The test piece numbers are Z01-QX0, Z02-QX01, Z03-QX02 and Z04-QX03 respectively.

If it is serious, it will threaten the overall safety of the structure and affect the seismic performance.

QX01, QX02 and QX03 indicate that 232mm, 278mm and 325mm foam adhesive is wound in the middle of No.

Zhongnan Construction then upgraded and developed the system, and developed the NPC slurry anchor system with Chinese characteristics [1].

Table 1 Steel performance parameter Table 1 Steel diameter fy (Mpa) fu (Mpa) ε y(10- ε) Es (Gpa) 10428.5613.83752193.516459.7622.13594203.8 C35 commercial concrete is used for concrete.

Z01-QX0Z02-QX01Z03-QX02Z04-QX03 Concrete 39.742.540.243.4 Grout anchor materials 65.3172.578.981.561.3 The axial compression ratio of concrete columns with test loading system and test point arrangement is designed as 0.3.

During grouting, the lower hole shall be used for grouting to ensure that the grouting is dense.

Precast concrete structure is composed of precast components connected by reliable nodes.

QX0 is a defect free component, which is regarded as a comparison piece.

Ma Junwei [3] and others conducted tension and compression tests on 144 different types of mortar anchor lap specimens, and concluded that the mortar anchor lap connection restrained by reinforcement is a reliable longitudinal reinforcement connection mode for precast buildings.

Qian Jiaru [4] et al.

1 Schematic Diagram of Column Reinforcement FIG1 schematic diagram of column reinforcement The column body and the foundation base are connected by lapping with embedded corrugated pipe mortar anchor, the diameter of the corrugated pipe is 40mm, the length of the reserved reinforcement at the base is 530mm, and a 20mm thick mortar setting layer is set.

The grouting defect is simulated by wrapping foam glue on the reserved reinforcement.

During installation, the perpendicularity and levelness shall be adjusted first, then the support shall be used for fixing, and then the grouting shall be carried out.

Three groups of test blocks are made for each batch of concrete to measure the compressive strength of the 28 day cube test block.

2 Schematic Diagram of Defect Layout FIG2 schematic diagram of defect layout 1.2 Material Properties Three kinds of reinforcements for the column shaft are taken for material property test to measure the yield strength, ultimate strength and yield strain.

Before yielding, the specimen shall be loaded once to yield in an increment of 30kN at each level.

First, apply axial pressure to the specified value and keep it unchanged, then apply horizontal thrust.

Liu Jiabin [2] and others conducted an experimental study on the seismic performance of the shear wall with mortar anchor connection of corrugated pipe restrained by rectangular spiral stirrups, and concluded that the ductility, bearing capacity and seismic energy dissipation capacity of the connection component are basically equivalent to those of the cast-in-place structure.

The column body size is 400mm × 400mm × 1500mm, 16mm diameter HRB400 reinforcement is used as longitudinal reinforcement, and 10mm diameter HRB400 reinforcement is used as stirrup.

The grouting material is grout anchor grouting material, and the fabrication is 40mm × 40mm × 160mm prism test block, measure the 7-day compressive strength of the prism.

After yielding, the specimen shall be loaded by displacement control.

A strain gauge is arranged at the bottom of the middle part of the end of the reserved reinforcement and 30mm below the upper surface of the foundation base, and a strain gauge is arranged at the middle and end of the spiral stirrup.

The performance parameters of reinforcement are shown in Table 1.

The size of column cap is 400mm × 400mm × 800mm, poured together with the column body.

Fig.

As the corresponding construction technology of precast buildings is still in the development stage, it is inevitable that there will be engineering quality problems of varying degrees during the construction process, which may cause quality problems of key nodes such as grouting defects.

The size of concrete base is 1400mm × 1400mm × 500mm, one-way reinforcement.

Displacement meters are arranged at the top, middle and bottom of the column to measure the displacement change under different column heights.

Densify 500mm above the column bottom and configure spiral stirrups.

The spacing between spiral stirrups is 100mm, the spacing between stirrup densification areas is 100mm, and the spacing between non densification areas is 150mm.

conducted a quasi-static test on the shear wall connected with mortar anchors, which proved that the indirect splicing of mortar anchors can effectively transfer the stress of reinforcement.

In order to study the impact of grouting defects on the seismic performance of mortar anchor lap joint columns, a quasi-static test of four mortar anchor columns is designed.

Table 2 Parameters of Concrete and Grout Anchor Materials Table 2Concreteandslurryanchorparameterstable Specimen No.

Domestic experts have also made a lot of exploration and research on the slurry anchor system.

This paper is based on the national key research and development program “Key Technology for Inspection and Evaluation of Industrial Buildings”.

The reliability of the connection mode directly determines the integrity and seismic performance of the structure.

Specific data are shown in Table 2.

The main reinforcement is HRB400 reinforcement with a diameter of 18mm, in the form of mixed stirrups.

Column loading and measuring point arrangement are shown in Figure 3..

3, 4 and 5 longitudinal bars respectively, and the defect length accounts for 40%, 50% and 60% of the anchorage length.

The defect location is shown in Figure 2.

The specific reinforcement form is shown in Figure 1.

1 Experiment overview 1.1 Design and manufacture of test piece The mortar anchor lap joint column test piece is assembled from the base and the column body.

Yuhui Group and Harbin Institute of Technology devoted themselves to the research of precast buildings, and proposed a binding mortar anchor lap joint system.