How to do the detailed design of assembly project? Learn from this project!

When this link is implemented, the architectural scheme has been basically determined.

The work content of the deepening design of precast components is to convert the design requirements of all parties into construction drawings with strong operability and reasonable design.

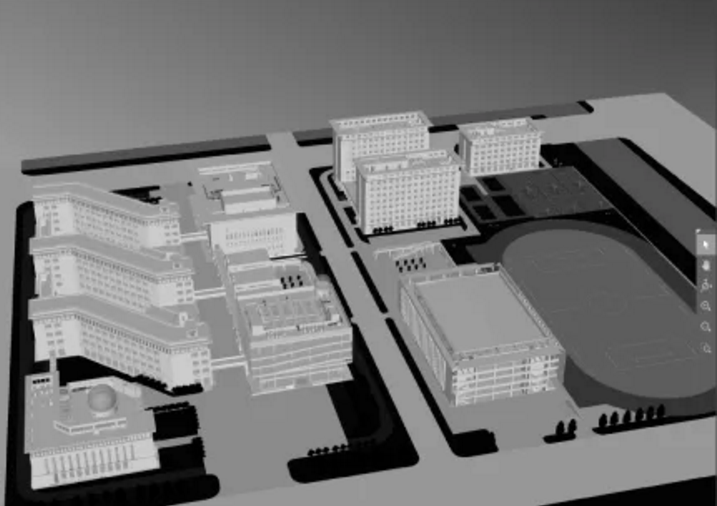

Let’s take a case to illustrate how to carry out the in-depth design of assembly project? 1 project overview the assembly area of the project mainly includes teaching building, administrative building, concert hall, student apartment, teacher apartment and gymnasium, as shown in Figure 1.

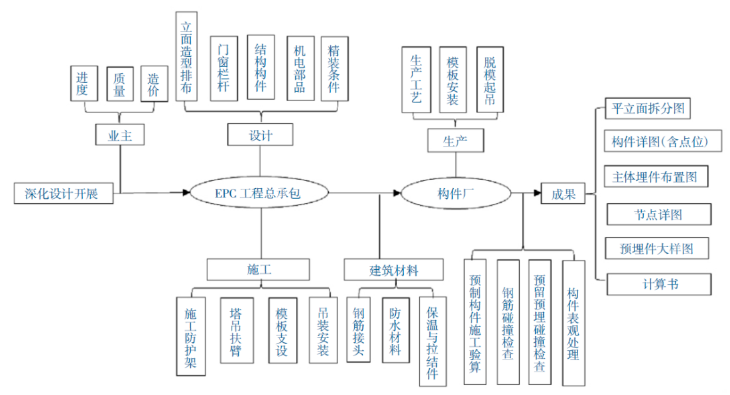

The construction process is shown in Figure 2.

The prefabrication rate of some single buildings has reached 55%.

The characteristics of building industrialization under the whole industry chain collaborative general contracting mode are closely related to the five characteristics of “standardized design”, “industrialized production”, “assembly construction”, “industrialized interior decoration” and “information management”.

The design work is not only a problem for designers and owners, but requires the active participation of all stages and parties, including component processing plants and construction sites, to make an overall analysis of the manufacturing and assembly links of various subsystems of architecture, structure, electromechanical and decoration, and finally get a satisfactory result for all parties.

Perhaps this process is very long, but it is indispensable.

This process will inevitably involve the cross cooperation of various disciplines.

Only through reasonable deepening design process and accurate grasp of the key points of deepening design of various disciplines, can we realize large-scale manufacturing and efficient lean assembly, give full play to the comprehensive advantages of precast buildings, and solve the new problems of deepening design of precast components.

The relationship between deepening design and the whole industrial chain.

Under the general contracting mode, as the only party for the integration and integration of the whole industrial chain and the final confirmation of design results, the general construction contractor not only makes the work interface clearer, but also defines the responsible subjects of all parties, so as to avoid the lack of depth and accuracy of design results caused by the limitations of the working ability of designers of a single party, and effectively improve the deepening design efficiency, So that the coordinated implementation of the whole industrial chain can be promoted in an orderly manner.

In the construction scheme stage, it is necessary to determine whether a series of engineering practices are easy to realize and how difficult it is to implement from the perspective of the whole industrial chain; In addition, in the preliminary design, we also need to consider the modularization and standardization of components, because the design focus of precast projects is to study the splitting scheme and standardized finalization scheme of precast concrete.

After the design scheme is determined, repeated modification and adjustment shall be avoided as far as possible to achieve one-time fine drawing as far as possible.

The project simplifies the reservation and embedding of each discipline and construction link into embedded parts with accurate positioning and marked specifications, After the general contractor of the construction carried out the embedded parts inspection, it gave feedback to the component factory.

Considering the impact of seismic structural tie bars set by traditional secondary masonry materials on reservation and embedding, all secondary masonry walls adopt precast lightweight cantilever partition walls.

4.

Because the general contractor has strong comprehensive ability and more construction experience, it can integrate and simplify the design needs of all parties more accurately, no longer specifically reflect the specific needs of each discipline, but abstract and symbolize the needs of each discipline.

In the process of deepening design, first start with the architectural scheme and according to the design principles of architectural industrialization project, The plan split diagram focuses on the connection mode between components and main body and the connection mode between components.

In EPC mode, the management becomes systematic.

After all the requirements of the above links are summarized, the construction general contractor will review the drawings, so as to effectively improve the quality of in-depth design.

Moreover, the design institute shall strictly control the drawing quality and avoid repeated communication and modification in the later cooperation process.

Taking the project as an example, combined with the problems and solutions encountered in the process of deepening design, the following describes the relationship between the deepening design of precast components and design, production, construction and other links: the collaborative project in the stage of deepening design and full professional design.

PC component types mainly include precast columns, composite beams, composite floors and precast stairs, and the overall prefabrication rate has reached 30.1%.

Therefore, the key to the implementation of assembly building technology is to form a whole industry chain in the links of design, production, construction and management.

The component factory carried out secondary deepening according to its own production process requirements.

Figure 2 construction process of precast building in EPC project, cost control should be considered first.

As a key link connecting design, production and construction, deepening design plays an important role in the whole industrial chain.

The deepening design of assembly projects must focus on the needs of all parties.

Finally, through communication and coordination with the general contractor of the construction, it integrated the embedded parts of the construction lifting point with the components demoulding and lifting embedded parts, and finally realized the “one buried and multi-purpose” of reservation and embedding.

The elevation split diagram shows the detailed layout of finishing materials, and focuses on the waterproof practice of component joints.

At the same time, the deepening design of precast components should actively cooperate with the construction unit and the design unit in the scheme stage, according to the professional design requirements of building structure, plumbing and electricity, fine decoration and in combination with the component production process and construction and installation conditions, Optimize the architectural scheme and complete the preliminary design of precast components.

Click the “blue word” above to focus on more highlights.

At this time, it is necessary to reasonably modify the architectural scheme according to the modular principle.

At the same time, an important factor affecting the production of precast components is the mold cost.

Figure 1 site layout of the project 2 preliminary preparations in the stage of special assembly planning, the designer of precast components should understand the local policies of the project.

For small metal precast components such as door and window railings, air conditioning panels and GRC external finishes, the conflict between the positioning of the above embedded parts and other reserved embedded parts and reinforcement shall be considered in the process of deepening design, so as to realize one buried and multi-purpose as far as possible..