How to do low temperature grouting of cast shear wall structure in winter?

3.

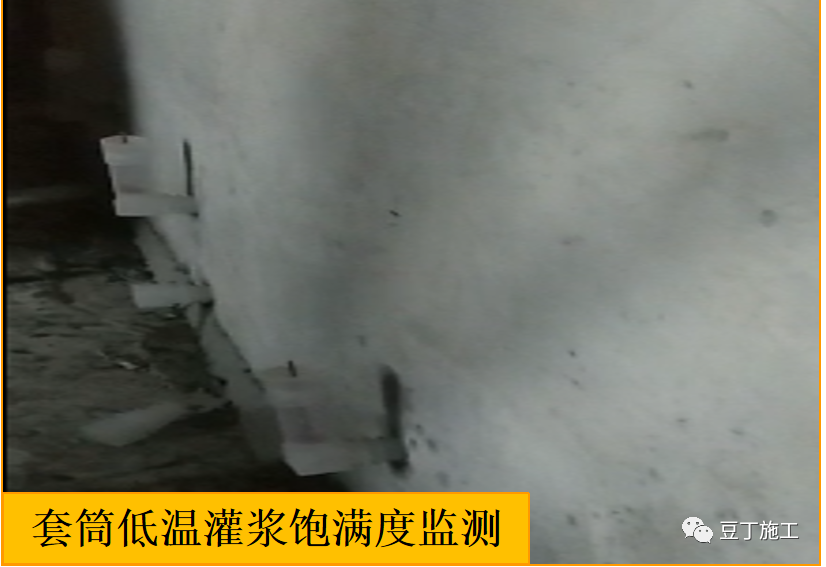

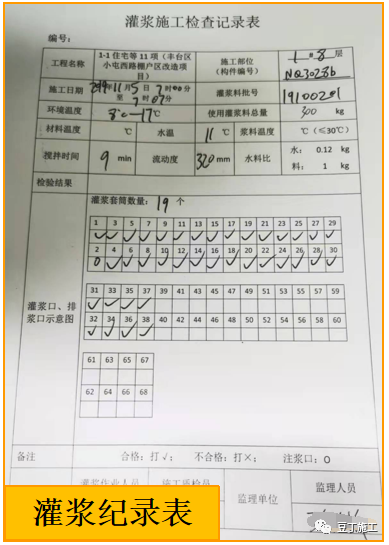

(3) Work of quality inspector: check whether the heating measures of the greenhouse are in place, check the verticality of the wall, stand by to check the whole process of grouting, record video data in the whole process, check the fullness of grouting and check the wall maintenance measures.

2.

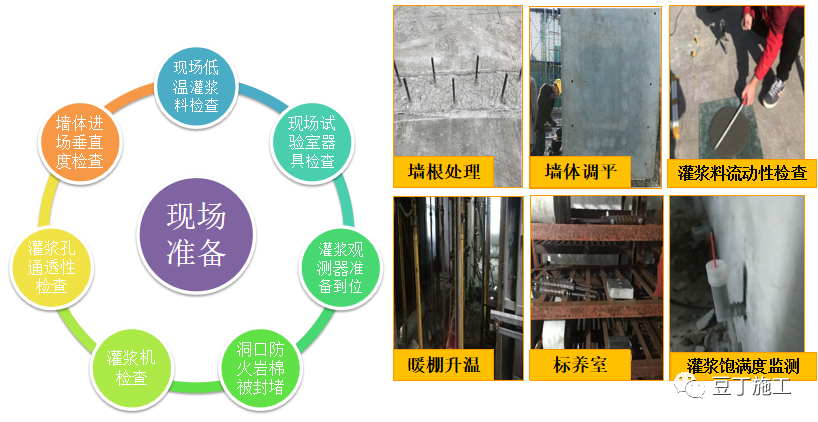

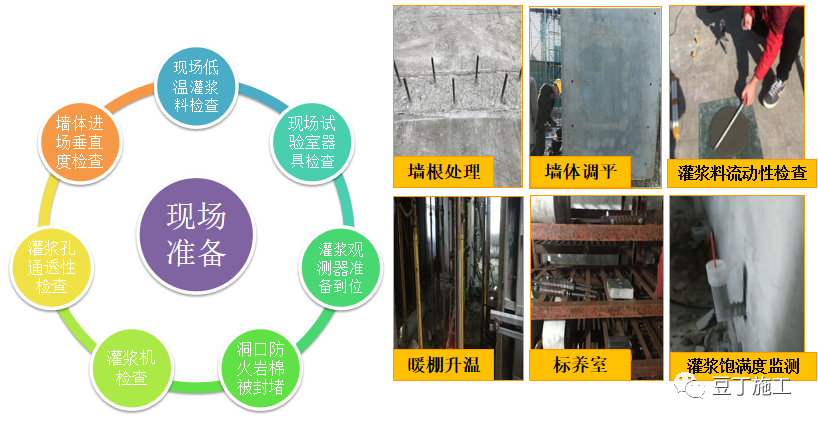

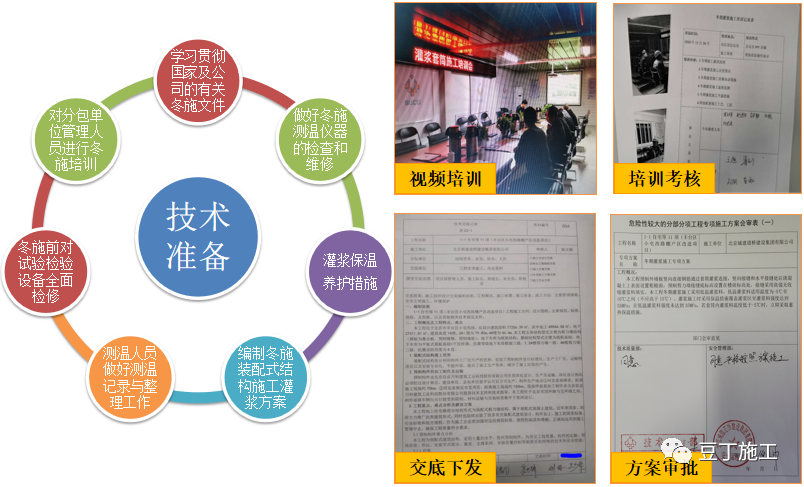

4、 Construction preparation 1.

(4) All electrical equipment shall be debugged and inspected once a week.

2、 Personnel organization measures # 1.

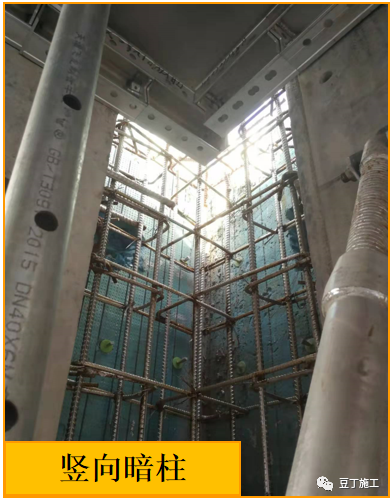

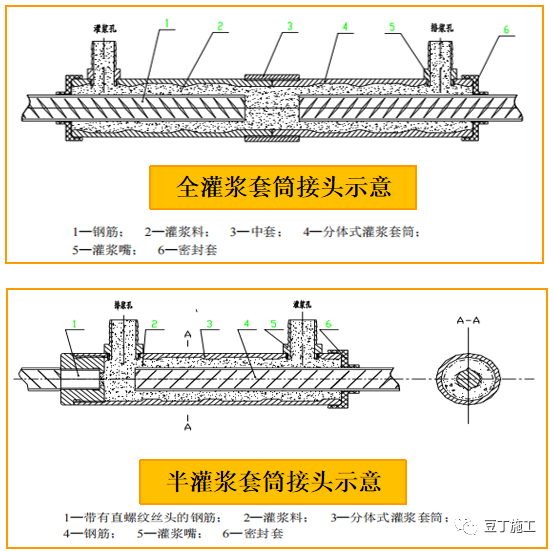

Precast wallboards are connected with full grouting sleeves.

Plugging measures for window opening plugging measures: aluminum alloy strip on the outside – Flame Retardant and fireproof insulation felt hung in the middle – double-layer film coated color strip cloth on the outside.

(4) Before the wall is hoisted, a 3 * 10 electric heat tracing heating belt is embedded next to the wall.

2.

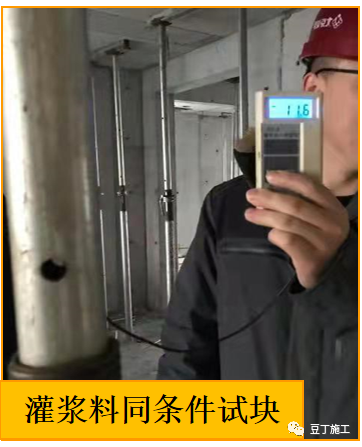

When the strength reaches 35MPa, stop the temperature measurement.

The heating and thermal insulation measures are different from the winter construction of conventional cast-in-situ structures.

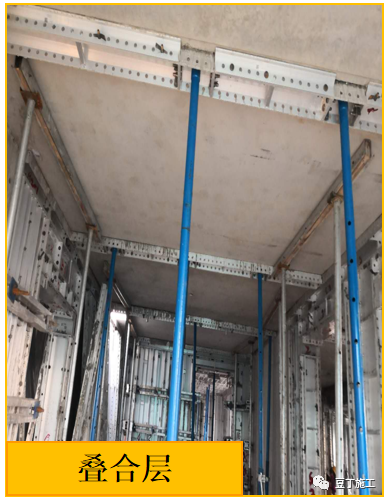

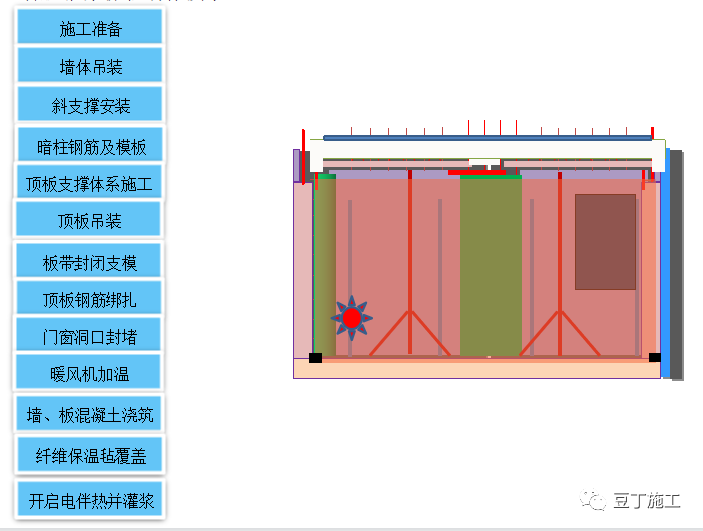

Construction preparation for the overall process of precast wall construction → wall hoisting → wall pouring node reinforcement and formwork construction → secondary leveling of wall → construction of roof support system → arrangement of thermal insulation and heating measures → hoisting of roof components → reinforcement Layout of water and electricity pipelines (including core barrel wall) → concrete pouring of roof wall → roof insulation → grouting mortar plugging → grouting material construction → heating and curing → removal of heating system.

Personnel safety measures (1) all personnel shall receive special safety education and pass the examination.

Pull out the rubber plug of the wall in time and stick it to the wall for heating, but it must be ensured that the slurry on the wall has solidified.

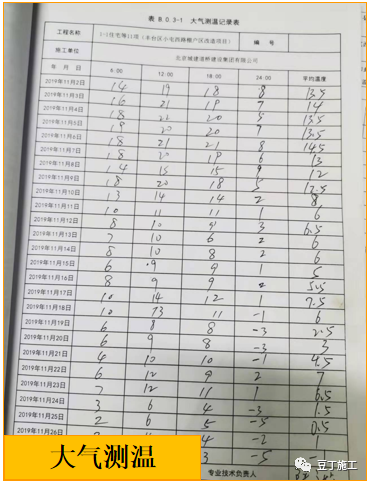

Only when the temperature of wall drilling temperature is above 5 ℃, can grouting operation be organized; During and after grouting, measure the temperature every 2 hours.

3.

2.

It is found that the temperature of the slurry at night is lower than 5 ℃.

(1) Work of the tester: record the atmospheric temperature measurement, measure the temperature of the grouting hole and the greenhouse every 6h, make the grouting material test block, and make the grouting sleeve parallel test piece.

The management personnel shall organize low-temperature grouting in winter, and set up 1 full-time tester, 1 full-time technician, 2 full-time quality inspectors and 2 constructors.

On site implementation standard} 4.

Organization of operation team members (1) there are 6 grouting team members and 1 team.

(3) Cavity temperature: before wall hoisting, electric heat tracing shall be arranged at the same time when the PE strip of the outer wall is arranged, and it shall be opened during grouting.

(2) The roof and wall support system adopts aluminum alloy formwork system.

(3) Fire extinguishers are added, and each unit is equipped with 4 fire extinguishers.

construction technical measures 1.

Construction process 1.

(2) Each unit is equipped with a special person to take care of the heater for 24 hours.

If the grouting time is immediately after the wall panel is hoisted and corrected, the closed thermal insulation system cannot be formed because the roof is not constructed..

I hope you can contribute more excellent works and get a thousand yuan scholarship, Douding architecture year member service and honorary certificate.

According to the winter construction period, the construction scope of low-temperature grouting in winter of the project is as follows: structural construction of 8-14 floors of 1#, 2# buildings and 4-8 floors of 4# buildings.

3、 Fire safety management measures # 1.

1、 Project overview the structural type of the project is the integrally assembled shear wall structure.

(2) Technician’s work: publicize and implement the winter construction specifications and requirements, issue the scheme and disclosure, check the implementation and provide on-site construction technical guidance.

(2) Diesel air heater is equipped with one set every 50 square meters and about 8 sets on each floor.

On site safety measures (1) all secondary and tertiary boxes are equipped with encapsulated cables and wires, and new products are adopted.

Site preparation 5.

Fire protection measures (1) fireproof and flame retardant rock wool quilt + aluminum alloy strip shall be used for hole plugging.

There are three residential buildings in total, with 28 floors for 1#, 2# buildings and 16 floors for 4# buildings.

(2) The personnel shall be equipped with complete safety protection articles, insulating shoes, etc.

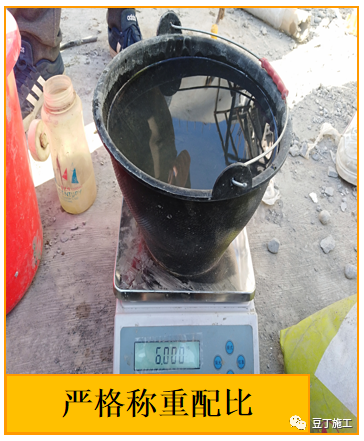

Grouting construction process construction preparation → embedding thermal insulation and heating measures → grouting mortar pointing → grouting slurry production → sleeve grouting → self inspection and working face cleaning.

3.

(3) All edge openings shall be closed with 1.5m high guardrail.

After the grouting is completed, the heating belt is powered on to generate heat, so as to ensure that the cold temperature outside does not enter the connecting cavity and compensate the heat loss of the grouting material, so that the temperature of the grouting material is constant above 5 ℃ during the hardening process.

Only the interior walls of the 1# building and 2# building of the project are precast structural walls, and the interior and exterior walls of the 4# building are precast walls.

Materials and equipment preparation 3.

According to the division principle of winter construction period in the code for winter construction of Building Engineering (JGJ / t104-2011), the winter construction is started when the outdoor daily average temperature is stable below 5 ℃ for 5 consecutive days, and the winter construction is cancelled when the outdoor daily average temperature is higher than 5 ℃ for 5 consecutive days.

(4) Work of constructors: implement the closure measures of greenhouse, temperature rise measures, maintenance measures in place, and fill in the inspection records of low-temperature grouting.

Technical preparation 2.

Before grouting construction, temperature shall be measured every 30 minutes, and the temperature shall be stable above 10 ℃ for three consecutive times.

2.

(2) All operators shall enter the operation team after receiving special training, passing the examination and issuing work certificates.

Author: Wang Xu Description: This article is “I’m the best in winter, show my style!” (← click for details) the submission works of the activity.

The submission time of this activity is up to January 31, 2022.

Due to the small section of cast-in-situ joints and the need for sleeve grouting, the thermal insulation work of the following three links should be paid attention to in the winter construction: (1) ambient temperature: heat the working area with diesel air heater to ensure the closed ambient temperature of 10 ℃ – 15 ℃.

Low temperature grouting process action demonstration VI.

When the curing temperature is lower than 5 ℃, the emergency standby 200 high-pressure heater is used to heat both sides of the wall, Focus on monitoring the temperature from 20:00 PM to 8:00 am.

Sealing of door opening: Hang double-layer flame-retardant rock wool quilt – hanging angle steel drop angle at the bottom.