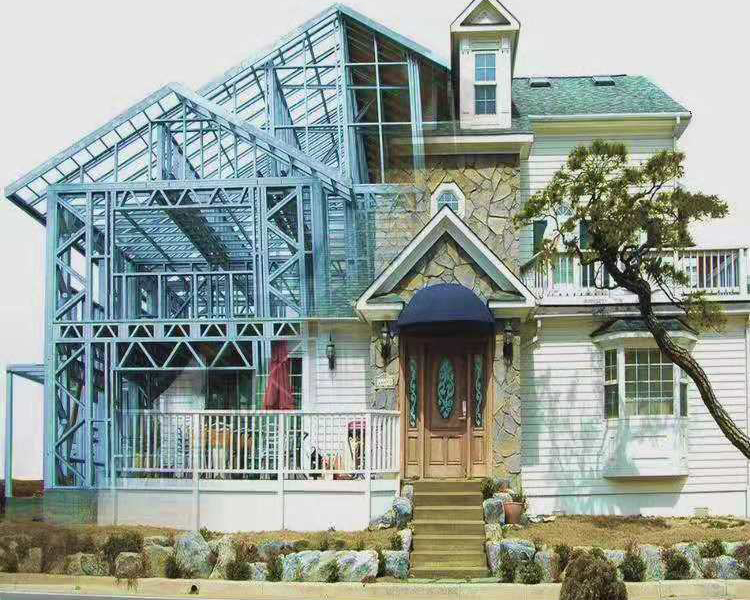

Do you like the beautiful precast villas rising in the countryside? What is the difference between it and rural self built houses

The traditional self built houses rely on the experience of the construction team.

The precast building itself is light and the structure is relatively simple.

Due to the limitation of production equipment, it is difficult to produce large components.

The complete combination of lightweight concrete wallboard and ring beam can greatly reduce the bonding joints of blocks.

Many farmers have a dream of living in villas.

Application field, it is suitable for buildings with few floors and low total building height.

If the customer has renderings, you can know what the house will look like after it is built.

Every step needs to be leveled.

The pre supported components include exterior wall, interior wall, floor slab, balcony slab, staircase, roof, beam column, etc, These products can be produced in the factory within a few days, and then transported from the factory to the construction site for finished product assembly and hoisting.

After pouring, the wood plate needs to be sealed for finished product protection.

It basically costs hundreds of yuan, which is about to account for one third of the house cost.

The foundation and foundation usually adopt concrete independent foundation or strip foundation, which can reduce the bearing capacity requirements of the foundation.

However, the traditional self built houses of farmers are basically the same in shape due to the lack of design, The functional area is also simple, and gradually can not meet the vision and needs of rural people.

The main body of buildings with small area can be completed in half a month.

The integrity and seismic performance of the structure are usually higher than those of ordinary brick concrete structures.

Some of them have a single and uniform shape, and there is no pre effect drawing for exterior wall decoration and decoration.

01 the construction period is short.

only after the customer is satisfied, can you deepen the structure, component production and decoration material configuration in the later stage according to the drawings.

The traditional brick concrete structure requires a series of work such as on-site formwork erection, reinforcement binding, concrete mixing, formwork pouring, masonry and maintenance.

The market standardization has not been formed and the price is not transparent.

Walls, beams, columns, floors and roofs are assembled one by one, so there are not many manual and technical types of work, Basically, it is enough to have a construction technical guidance and three or four adult labor forces, while the traditional brick concrete structure, carpentry, reinforcement workers and plasterers.

03 the design is novel and the appearance is beautiful.

Light steel, heavy steel, wood and prestressed concrete (PC) can be built as precast buildings.

After drawing a sketch on the site, the setting out began to construct.

They all have a common feature.

1.

What are the advantages and disadvantages of it and the traditional brick concrete self built house.

In short, with these advantages, precast villas still have great prospects in the rural market, and the state also vigorously promotes precast buildings.

The size limit is not suitable for long-span buildings.

Of course, there are some noteworthy places for precast building villas.

In addition, there are small workers in various processes, such as brick picking, concrete mixing and reinforcement cutting.

At this time, there is a new type of precast villa, which has attracted the attention of rural people with its novel appearance.

A large number of building components are produced and processed by the factory workshop.

Lightweight concrete wallboard structure has only 40% – 80% of the weight of traditional concrete.

2.

Take the stairs for example, the traditional on-site construction is particularly troublesome.

At present, rural labor is more expensive.

Based on experience, they feel that the color and style matching is not good-looking, and there is no way to do it on site.

Large workers spend 280290 a day and small workers 150160 a day.

3.

The designer will design according to the needs of customers, from the layout of plane functional areas, When it comes to the design of indoor and outdoor decoration renderings, if you are not satisfied, you can communicate with the designer to change the material mix at any time, such as color, decoration style, etc.

With the development of economy, farmers who work or do business in other places have earned money and have the strength to go home to build villas, which is convenient for returning home to provide for the elderly or for their sons to get married.

02 requires less labor and simple assembly.

The freight is high.

If the component production plant is far away from the construction If the site is too far away, the transportation cost will be very high.

Trapezoid Rubber Magnetic Chamfer

05 less material waste, energy conservation and environmental protection.

4.

Since most components of precast buildings are precast in factories and assembled on site, the turnover process of materials is reduced, the material loss is less, the construction waste is not much, and the site cleaning is relatively simple, And the cast construction is “dry construction” “, compared with the construction of traditional buildings, the demand for water and power resources is much less, the construction noise is also small, and the impact on the living of the surrounding neighbors is small.

From the development trend of the construction industry, precast buildings conform to the subdivision direction of the future development trend, and interested friends can learn more about it..

The formwork can be removed in 28 days under the condition of air drying, If the maintenance is not enough, the direction of horse face honeycomb is easy to appear.

Generally, the villa models of assembly manufacturers and villas of various styles can be selected by customers.

04 the self weight is low and the seismic performance is good.

Precast buildings include many new building systems.

The labor cost of this piece is relatively large.

The cost of shoveling off and redoing is too high.

This should be the most eye-catching.

This is because the precast villa has not been popularized in rural areas, and customers do not know much about these, Do not understand the normal market price of the house, do not know what the specific material configuration of the house is, and some manufacturers compete at low prices in order to attract customers, taking poor materials and shoddy them.

For precast house construction, because most components have been precast in the factory, it only needs to be assembled like building blocks on site.

Customers can also ask the designer of the manufacturer to carry out special design according to the size of their foundation.

There are no more than ten or twenty people on site, so they can’t rotate.

In recent years, there has been a trend of building villas in rural areas.