Common quality problems and prevention measures of precast buildings, all aspects of design, production and construction!

If the site is uneven, the cushion blocks need to be adjusted to ensure that the bottom cushion blocks are in the same plane, Ensure that the precast components at the bottom layer are placed flat and stressed evenly; Second, the number of stacked layers of laminated plates should not exceed 5; Third, there shall be no lack of cushion blocks between plates, and the vertical cushion blocks shall be in a straight line, and all cushion blocks shall meet the specification requirements.

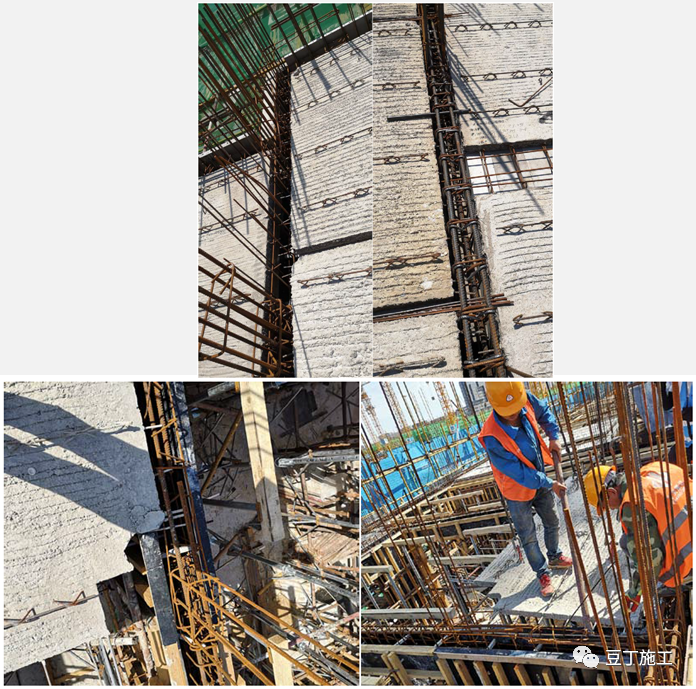

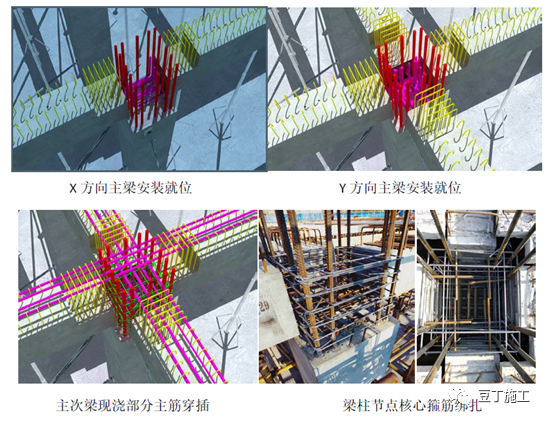

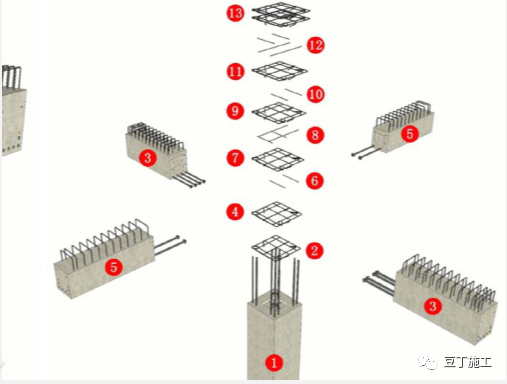

(2) during construction, establish the construction BIM of this node, check the reinforcement collision, reasonably arrange the process, reasonably insert and cooperate the process, reasonably layer, demonstrate the hoisting sequence according to the reasonable process, improve the construction efficiency and reduce the waste of construction period.

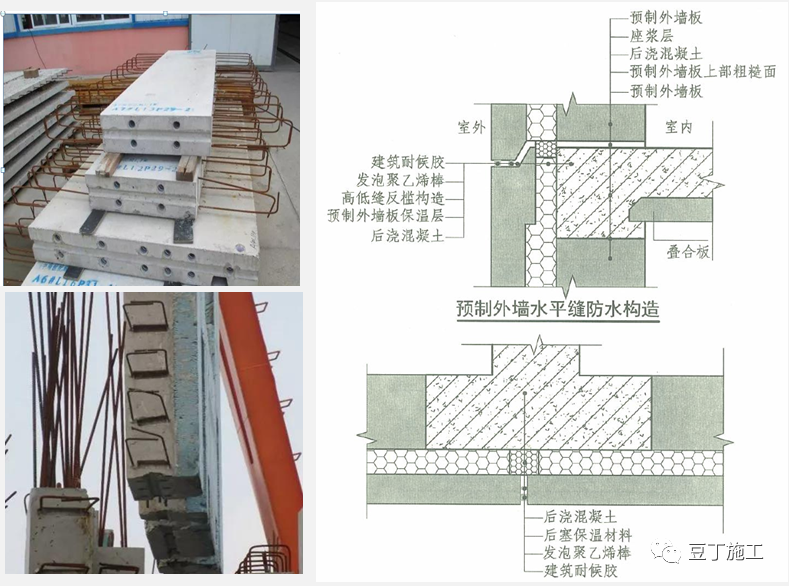

Waterproof structural measures shall be taken at the joints.

Establish the layered flow chart of beam column joints and primary and secondary beam joints according to the BIM demonstration, and carry out the hoisting of composite beams and binding of column stirrups according to the sequence of the flow chart.

Design part 1) the hoisting efficiency at the beam column joint is slow, the reinforcement collides, and the process is unreasonable, which often leads to rework | cause analysis: at the beam column joint, due to the dense reinforcement and limited space, the column main reinforcement, column stirrup and beam reinforcement in four directions extend into the joint, resulting in reinforcement collision, complex reinforcement levels and unreasonable hoisting sequence Unreasonable process coordination causes construction confusion and low efficiency, which affects the construction period of the structure.

When the upper and lower rows of wooden cushion blocks are not in a straight line, it is very easy to produce crack correction measures.

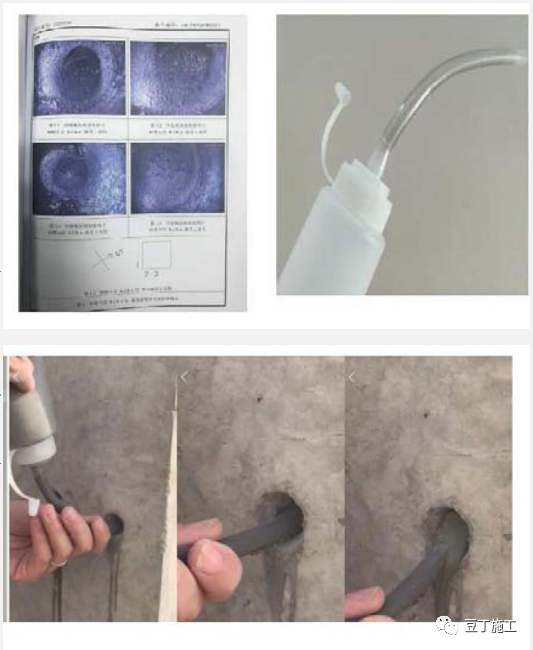

After the mold making agent is applied, the reasons for the formation of air holes are analyzed, Easy to form air holes (3) concrete vibration is not dense and deviation correction measures (1) use water-based release agent or oily release agent to replace grease; (2) Before applying the release agent, the formwork must be cleaned.

(1) problems in site acceptance and stacking of precast components.

(2) Do a good job in the review of detailed design drawings and the first sample inspection.

It is not allowed to walk on the formwork coated with release agent; (3) The technical disclosure of concrete vibration shall be made to the workers, and the vibration process shall be on-site for one week.

Corrective measures (1) the design department shall design in strict accordance with the specifications.

(2) the wire box of the machine can be embedded in the precast laminated plate, the pipeline material can be changed to PVC, and the number of overlapping layers of pipelines at each position shall not exceed 2.

(2) Corrective measures for failure to reinforce according to the design before lifting and transportation (1) stiffeners shall be set at door and window openings and other positions according to the specification requirements (2) before lifting and transportation, the components must be reinforced according to the design requirements and can be lifted and transported only after passing the inspection.

4) The stacking height of the three layers of pipelines on the laminated plate exceeds the height of the post cast layer # cause analysis the project did not do the design Bim in the design stage, nor did the construction Bim in the construction stage, and did not carry out the collision inspection of electromechanical pipelines and reinforcement.

Set up factory resident representatives to master the production of components.

Cause analysis (1) the design of precast components is unreasonable; (2) The design of lifting point is unreasonable..

When stacking preset components, first, the stacking site must be relatively flat.

2.

Cause analysis (1) deviation of main reinforcement; (2) The length of reserved stirrups in the prefabrication processing plant is insufficient.

Sorting out | Douding construction 1.

Corrective measures (1) take corresponding remedial measures; (2) Strengthen the on-site construction management to avoid the deviation of reinforcement; (3) Feed back the information to the processing plant in time and redesign the extension length of stirrup to avoid similar problems again.

The gangway shall be used in the reinforcement binding and embedding process.

3.

2) The location design of the lifting point is unreasonable.

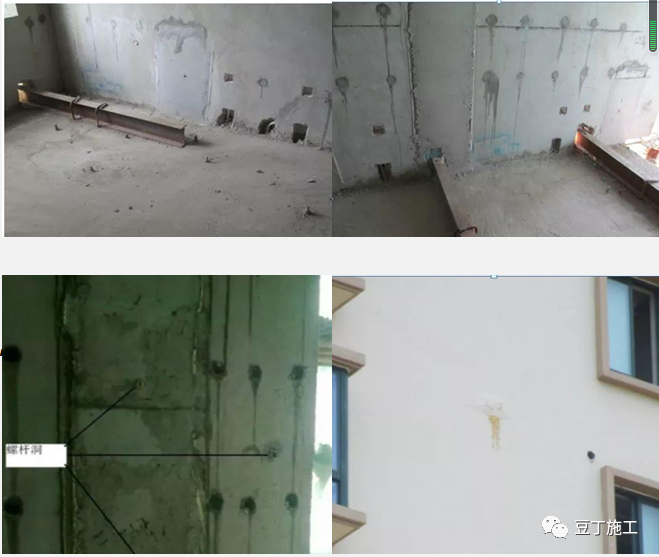

The embedded pipeline must be constructed according to the drawing without omission.

The horizontal joint of the component is designed to be 20mm, and the joint between the insulation board is directly filled with cement mortar.

The wallboards of some components of the outer wall are not turned up 600 according to the design No water stop groove is left, resulting in leakage of the outer wall.

Precast components are stacked at random on the site.

During the on-site lifting process, obvious cracks are generated and the precast components are damaged.

Strengthen the inspection before pouring concrete.

3) The pipeline of precast components is missing and inconsistent with the reservation on site.

Factory production part: (1) deviation and displacement of embedded position; (1) the wire box is not firmly fixed, and the wire box is displaced during concrete pouring or vibration; (2) corrective measures for concrete vibration to touch the wire box; (1) support must be added at the bottom of the embedded wire box on the upper surface of precast components; (2) during concrete vibration, it is required not to touch the embedded wire box The technical specification for precast concrete structures stipulates that the position deviation of embedded conduit and electric box on the centerline of the member plane is 20mm and the height difference is 0 ~ 10mm.

It is found that the embedded pipes of some precast components are missing and offset, resulting in problems such as chiseling the precast components during on-site installation, which is easy to damage the precast components.

4) The main reinforcement of the wall is not in the stirrup at the node, which brings hidden dangers to the safety of the structure.

After deepening the rectification measures, the drawings shall be reviewed and disclosed, and the design, construction and production shall be confirmed.

2) cause analysis of surface cracks of precast components (1) stiffeners are not set according to the specification requirements in the design drawings at door and window openings and other positions.

Strengthen the quality management of the factory.

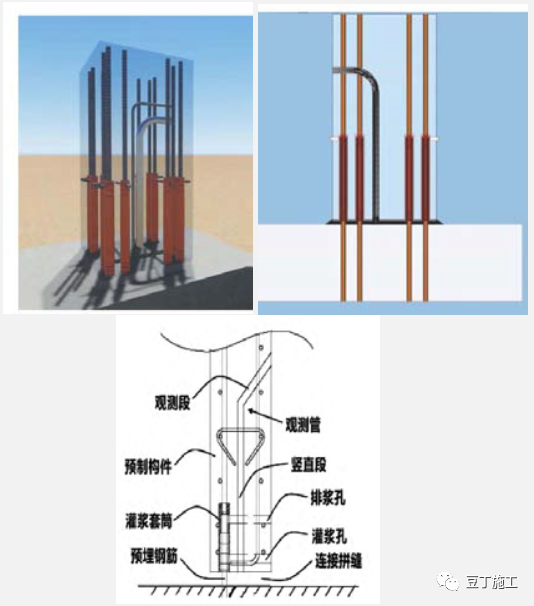

Corrective measures (1) establish the joint design Bim in the design, and solve the problem of reinforcement collision, such as the collision of beam main reinforcement in four directions and the collision between beam main reinforcement and column main reinforcement.

2) After the mold making agent is applied, the surface of the concrete is not easy to form air holes.

Therefore, this problem occurred.

Corrective measures (1) complete the design Bim in the design stage and carry out various collision inspections, including reinforcement and electromechanical pipelines; In the construction stage, complete the construction Bim and carry out various collision inspections.

Cause analysis (1) missing embedded pipe fittings during component processing; (2) The pipeline installation is not constructed according to the drawing.

Without water stop measures, it becomes an indirect water tank of the outer wall layer, which directly leads to leakage.

3) analysis of the causes of the lack of structural tongue and groove problems.

(3) hoist the composite beam according to the layered flow chart.