Fabricated steel structure + EPC + BIM, the application and process control of this cast project system are summarized in detail, which is

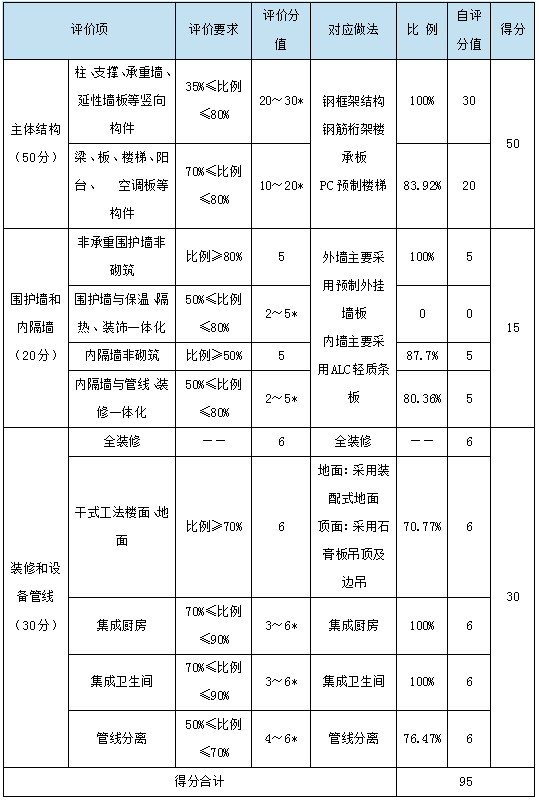

According to the evaluation standard for precast buildings (GB / t51129-2017), the assembly rate of the project is 95%, which is evaluated as AAA precast building.

Full discipline integrated design EPC comparison construction general contracting mode, The most direct change is the addition of “engineering design” responsibilities in the contract tasks of the contractor.

So far, it has obtained nearly 200 relevant patents, led and participated in the compilation of industrial standards and more than 20 provincial and ministerial topics.

The project is delivered for full decoration, and all cast decoration technologies are adopted, including cast wall and partition wall, cast ceiling, cast floor, integrated kitchen and integrated toilet to realize on-site building The surface is free of leveling, the wall is free of painting and pipeline separation, which is convenient for subsequent maintenance and renewal, and improves living comfort.

This paper will explain how to control the whole process of the project from the perspective of EPC mode management.

The company takes “product thinking” As a concept, it focuses on the research and development of precast steel structure building system, the combined application of green construction and low-carbon technology and integrated construction services.

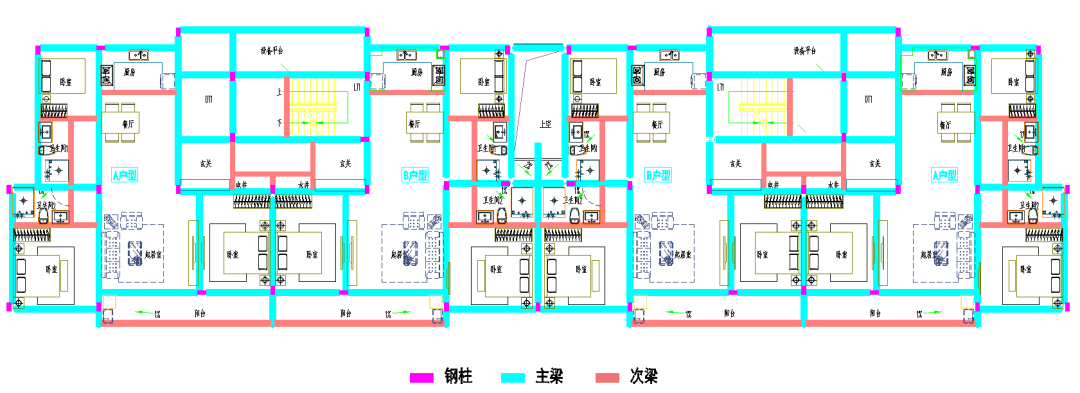

③ There is no steel column in the space used in the set, and the layout of steel beam shall consider the universality of ceiling during subsequent space transformation and the rationality of equipment pipeline passing through the beam.

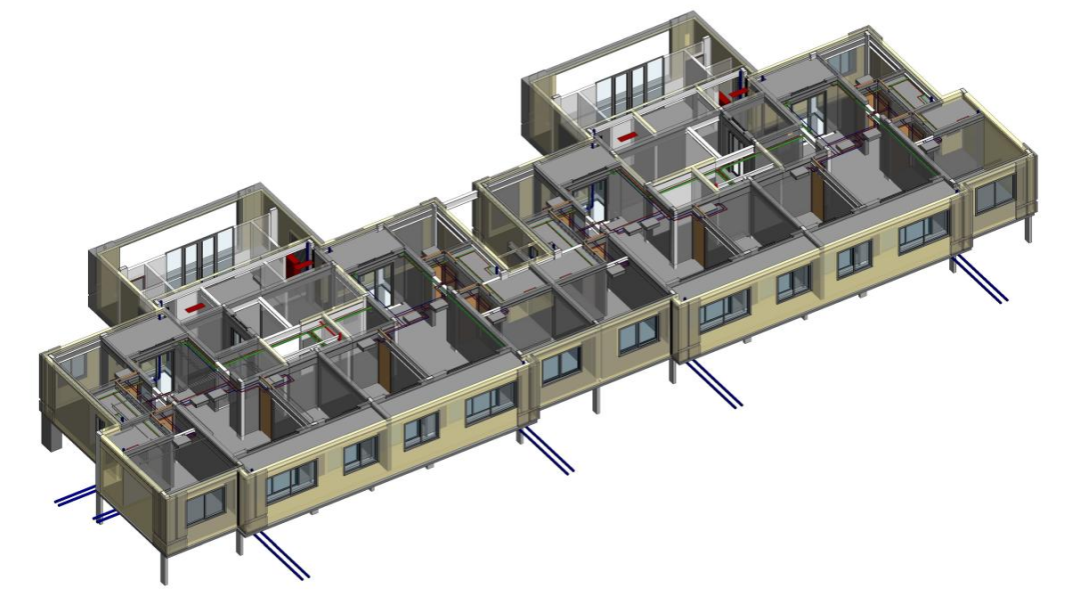

Longyuanmingzhu high performance • full assembly • steel structure building product system – S-system has the characteristics of building complete system integration and one-stop service ability, and the assembly rate can reach 95%; The system also integrates many elements such as green building, passive building, healthy building and sustainable development to effectively improve the comprehensive performance of buildings and the level of industrial construction.

Longyuan Mingzhu Technology Co., Ltd.

The whole system technology application of “high performance fully assembled steel structure residential products (S-system)” jointly developed by industry, University and research led by longyuanmingzhu is adopted for general contracting A residential project constructed under EPC mode has realized the whole system integration of structure, enclosure, electromechanical and interior decoration, fine management and one-stop service in the whole process of design, procurement, construction, delivery and maintenance, and the whole project has been greatly improved from construction quality, construction progress to residential quality.

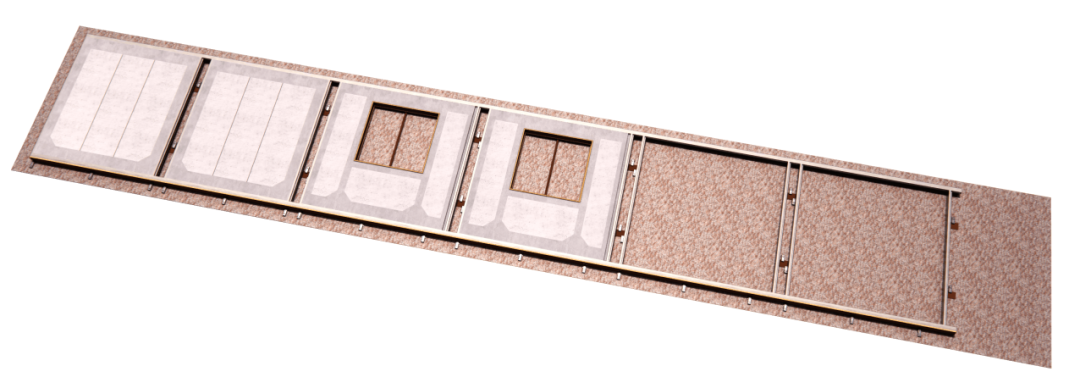

The floor layout does not have high requirements for lifting equipment, and the on-site reinforcement binding amount is reduced by more than 70%, which can well meet the needs of cross construction of steel structure buildings.

The structural design pays attention to the utilization of finished section steel, and the utilization rate of finished section steel is more than 85%.

Long Yuanming building gives play to the leading role of architects, effectively improves the coordination of structure, enclosure and interior decoration, improves the landing and fineness of drawings, selects parts and connecting nodes more suitable for the characteristics of the project, and the standardization rate of parts and components reaches more than 75%, At the same time, through the optimization of some parts, components and processes, the degree of construction assembly is improved, the project cost is reduced, and the construction efficiency and overall quality are improved.

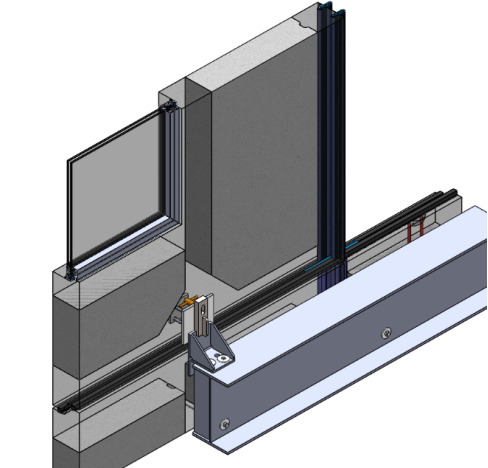

Method of building peripheral protection, embedding and hanging combination and connection diagram of precast external wall panel (2) The structural design project can adopt two structural forms of steel frame or steel frame support.

It has become the first complete cast steel structure residential system that has passed the evaluation of scientific and technological achievements of the Ministry of housing and urban rural development, and has been rated as “national scientific and technological achievements promotion project of construction industry” by the Ministry of housing and urban rural development.

Overall overview of the project: the project is an 8-storey steel structure residence, with a building area of 4006m2, a building height of 24m and no basement.

② The external wall panel shall comprehensively consider the adaptability to the structure and waterproof, adopt the dry hanging flexible connection mode, adopt the waterproof + water diversion combination for the wall panel joint, fully consider the building Bay and depth size for the wall panel separation, and comprehensively consider the applicability of processing, transportation and hoisting.

Through collaborative design with architecture, structure and electromechanical, the advantages of all disciplines shall be brought into play and the design quality shall be improved.

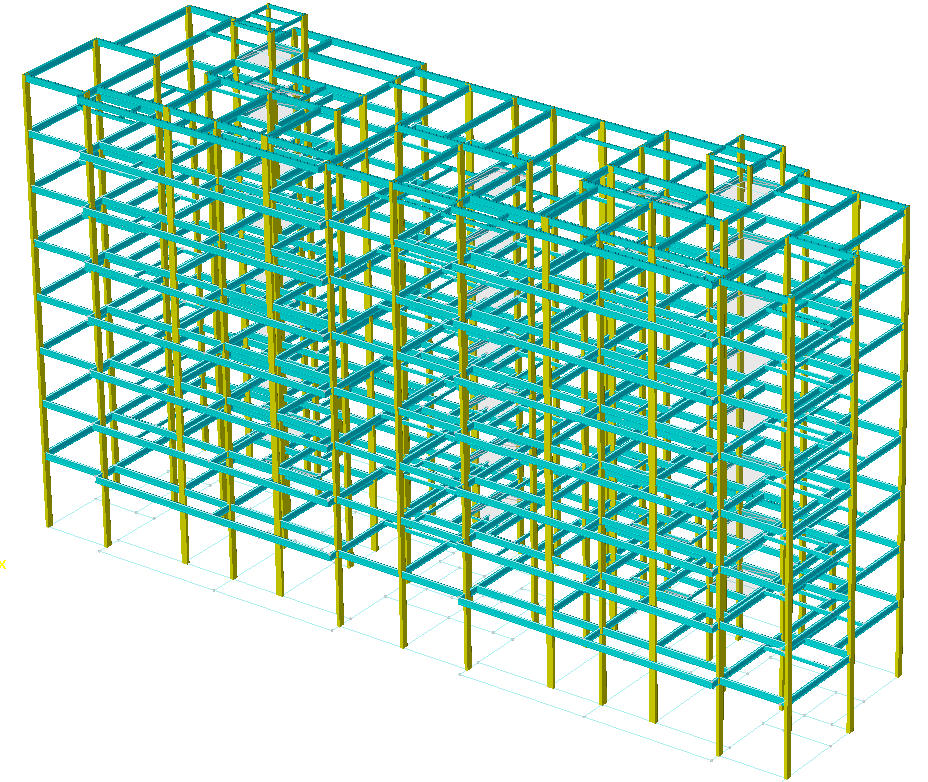

The structural model and structure The building diagram project adopts removable reinforced truss floor support plate.

After comprehensive comparative analysis, the steel frame form can better realize the subsequent variable space.

It is a strategic partner of the science, technology and industrialization development center of the Ministry of housing and urban rural development, a national precast building industry base Zhejiang construction industry modernization demonstration enterprise is a leading precast steel structure construction service provider.

▲ click the picture to register for the engineer conference.

In order to solve the problem of exposed beams and columns, the section width of beams and columns is controlled within 180mm.

(1) Architectural design the building shape of the project is simple and the plane is regular, which is more suitable to give play to the advantages of less specifications and more combinations of precast buildings, but the requirements of the facade are consistent with those of other buildings.

Because the project adopts precast external wall panels, if there is no beam and column exposure at all, the wall needs to be thickened, but it has an impact on the use space, which can be comprehensively solved in combination with decoration modeling and cabinet placement..

The design scheme is as follows: ① the external wall adopts precast external wall panels and embedded combination, and the thermal insulation is realized by the combination of wall self insulation and internal insulation, and the internal insulation is combined with the comprehensive test of precast decoration wall To meet the requirements of thermal insulation, sound insulation and decoration, and solve the problem of exposed beams and columns.

is a core subsidiary of Longyuan Construction Group (stock code 600491).

(3) Interior decoration design interior decoration design shall be carried out simultaneously at the initial stage of design.

Precast interior decoration display the effect drawing of precast interior decoration.

The on-site layout realizes no formwork and basically does not need to set support.

The technical application is as follows: structural system: steel frame structure, rectangular pipe column + H-shaped steel beam, PC precast stair floor system: removable reinforced truss floor support plate external enclosure system: self-developed precast energy-saving and light composite integrated wall panel internal partition system: ALC light strip decoration system: Precast decoration information technology application: BIM integrated design assembly rate calculation table: whole process control 1.