Only knock parameters without modeling, can domestic assembly software play so well?

China plans to reach the peak of carbon dioxide emissions by 2030 and strive to achieve carbon neutrality by 2060.

In the past two years, precast buildings have caught up with a major direction of Tianzi brand: carbon neutralization.

However, independent intellectual property rights are not used as the standard to judge the quality of a software.

The on-site pouring technology solves the problems of the previous era, that is, the production efficiency is low and it is difficult to scale.

II.

In fact, precast architecture is not a groundbreaking new technology.

If we tried to fall back, the ancient Neanderthals would build huts with the bones, jaws and teeth of large animals.

Speaking of this software, there are many sources.

The content is divided into three parts.

In 1958, the first batch of “large plate houses” appeared in China, and more than 10 million square meters of large plate houses were built in Beijing alone.

The first is to talk about the origin and current situation of precast architecture, the second is to talk about a domestic precast design software, and the third is to talk about our views on domestic software.

The labor and material consumption are large, and the construction must be suspended in case of bad weather.

The standardized module assembly and splicing can also meet the diversified building needs.

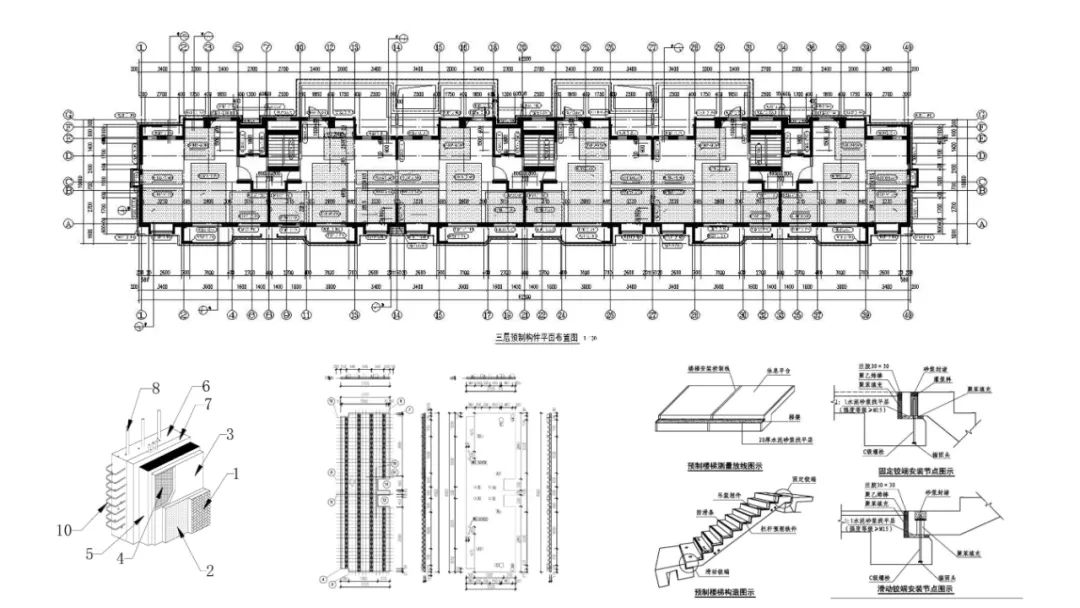

In short, pkpm-pc is positioned to meet the needs of different stages and roles such as submission and approval of cast scheme, structural modeling, integrated cast design, special cast deepening design and calculation analysis, so as to realize three-dimensional splitting of precast components, automatic generation of reinforcement and hoisting parts, generation of component details, output material statistics, establishment and maintenance of precast component library BIM data docking production and processing equipment and other applications.

Hello, this is bimbox.

Can domestic assembly software be typed? The software we want to talk about today is the domestic software pkpm-pc we just learned about recently.

➤ assembly meets BIM Technology.

The emergence and popularization of a technology must improve the efficiency or income of the whole society in some aspects.

From a certain point of view, it is a return to the ancients in a sense.

Shortly after the founding of the people’s Republic of China, the State Council issued the decision on strengthening and developing construction industrialization.

At that time, the wooden piles, beams, columns, boards and other components of the house were first pre processed with exquisite mortise and tenon joints, and then assembled on site.

The carbon emission of China’s construction sector accounts for about 20% of the country’s total carbon emission.

With the help of three-dimensional model, it can carry out in-depth design, drawing, component library and material statistics.

➤ in an ideal state, the decoration can be carried out simultaneously with the main construction, and only assembly and hoisting can be carried out on site to shorten the construction cycle.

In the 1990s, precast large slab houses withdrew from the historical stage because of their single house type and immature technologies such as waterproof and earthquake resistance.

The key is to see whether the software itself is easy to use and whether it can solve practical problems.

Production data can even be directly connected to factory equipment.

Under this background, green building and precast building will be a steadily rising industry in the next few decades.

At present, this improvement has not met the ceiling.

If we take the whole construction process as an example, in 2018, the total carbon emission of China’s construction process accounts for 51.3% of the country’s carbon emission.

At present, although there are still some problems, the precast building has achieved the following goals as a whole: ➤ through the modular splitting of the building, the components that can be mass produced can be formed, which has higher precision and more controllable quality than the on-site manual operation.

The following disadvantages are that many processes need to be completed on site, the construction cycle is long, the main body can be completed before construction, and the construction of the next floor can be carried out after the construction of the first floor.

When we say that precast architecture is “returning to the ancient times” in a sense, we do not mean that we have returned to the previous era, but follow the previous precast concept, and constantly solve various problems left at that time with new technology.

The earliest “precast architecture” in ancient China can also be traced back to about 7000 years ago.

China’s precast buildings have experienced several ups and downs in the continuous changes of technology and macro policies.

In 2016, shortly after the general office of the State Council issued the guidance on vigorously developing precast buildings, he got away from the structural technology of China Construction and Research Institute and undertook the national 13th five year key R & D project “application technology of BIM based precast building system”, and released the first edition of pkpm-pc at the end of the same year..

Today, we talk about precast architecture.

It was not until 2016 that the general office of the State Council issued the guiding opinions on vigorously developing precast buildings that the word “precast” returned to people’s vision, and relevant incentive policies were issued everywhere.

With the continuous emergence of new processing technology, installation technology and digital technology, precast evolved silently amid people’s doubts, A huge industry has been formed in a few years.

It means to realize the construction process of construction products by means of “standardized design, factory production, assembly construction, integrated decoration and information management”.

On the contrary, in modern times, with the invention of concrete, the construction began to adopt the method of concrete cast-in-situ.

➤ mechanization brings not only the cost reduction and quality improvement of individual components, but also the overall cost performance of all components can be improved with the increase of factory orders and technological innovation.

This method has the advantages of convenient construction materials, low cost and good integrity.

First of all, it is worth mentioning that the latest version of pkpm-pc is an assembly design software developed based on bimbase, which is a domestic BIM basic platform with completely independent intellectual property rights of Guli technology.

The phrase “build a house like a car” was put forward by architect Corbusier.