Application of BIM Technology in the design stage of precast building of supporting housing project in international low carbon City

The project is located in the Low-carbon City Industrial Park, Tiandi elevation Industrial Park, Longgang District, Shenzhen.

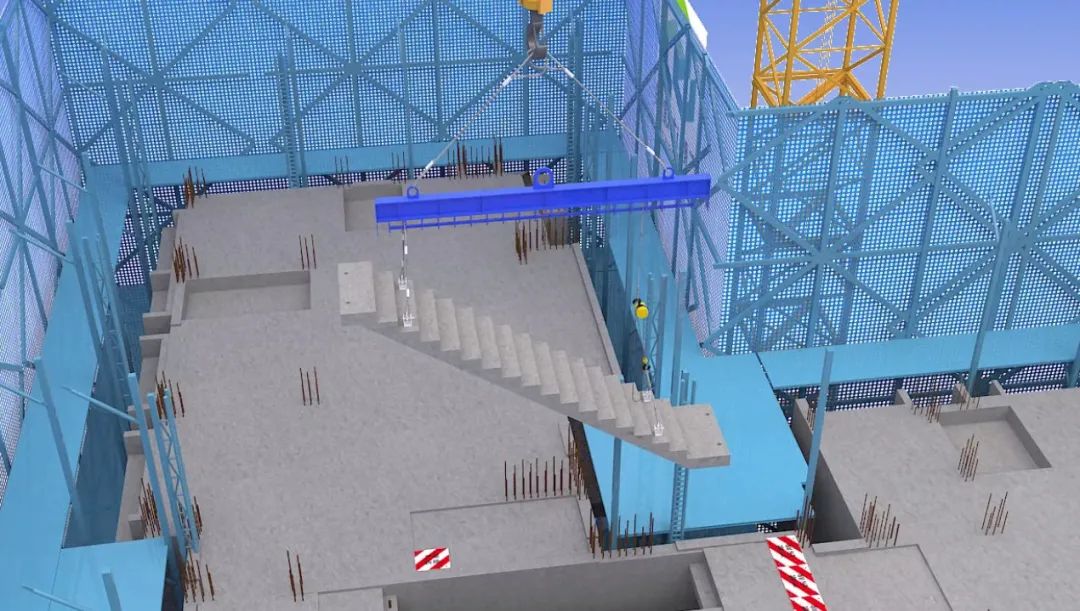

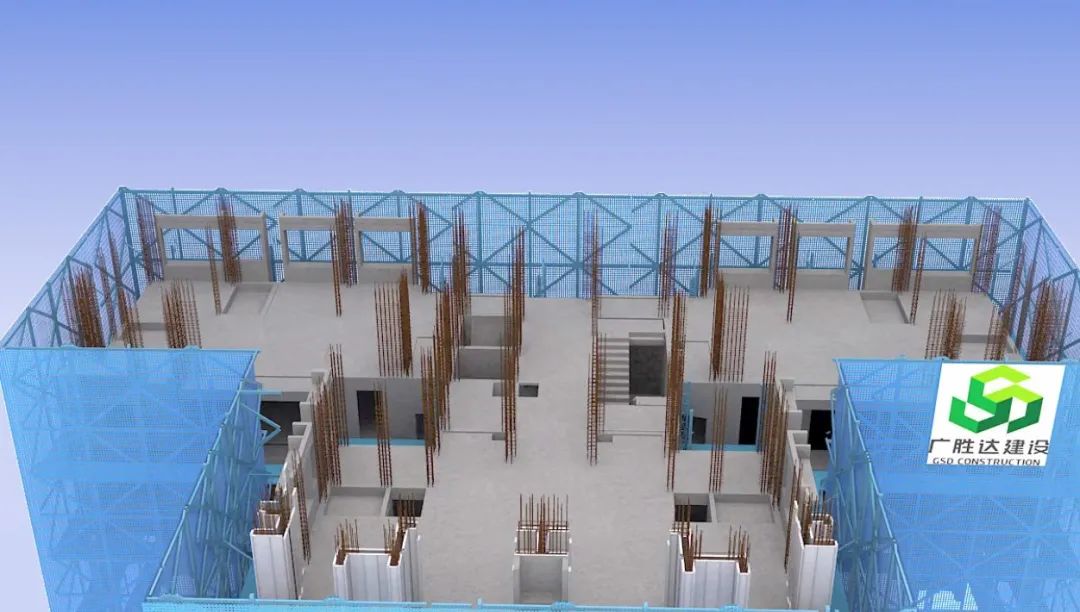

5、 The overall construction process simulates the hoisting of precast stairs on the standard floor, the cast-in-situ parts of precast components are interspersed in accordance with the hoisting sequence, and the aluminum alloy formwork is installed and reinforced.

It is adjacent to Shengjing road in the East, Shengye road in the north, Yanhe East Road in the South and industrial 1st Road in the west, and close to the outer ring expressway under construction.

The project applies BIM Technology to integrate the design drawings of various disciplines, conduct collision inspection and design optimization, manage and trace the problems involved, improve the design quality and design efficiency, and apply the Internet Engineering Management platform, Real time control of the on-site situation and quality of assembled construction.

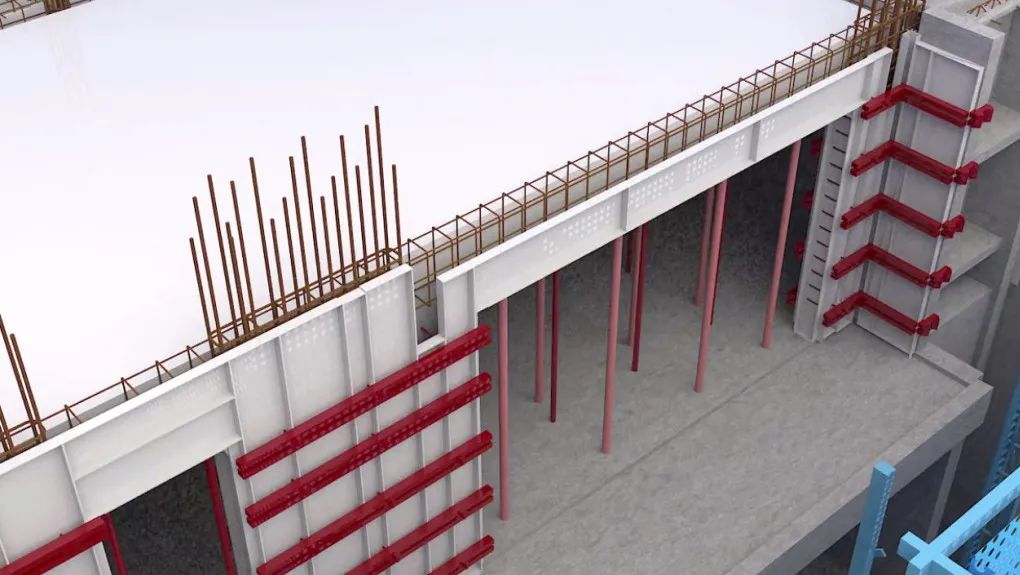

Uniformly bind floor beam reinforcement, reserve and embed water and electricity pipelines, bind slab reinforcement and pour concrete.

Introduction to BIM application.

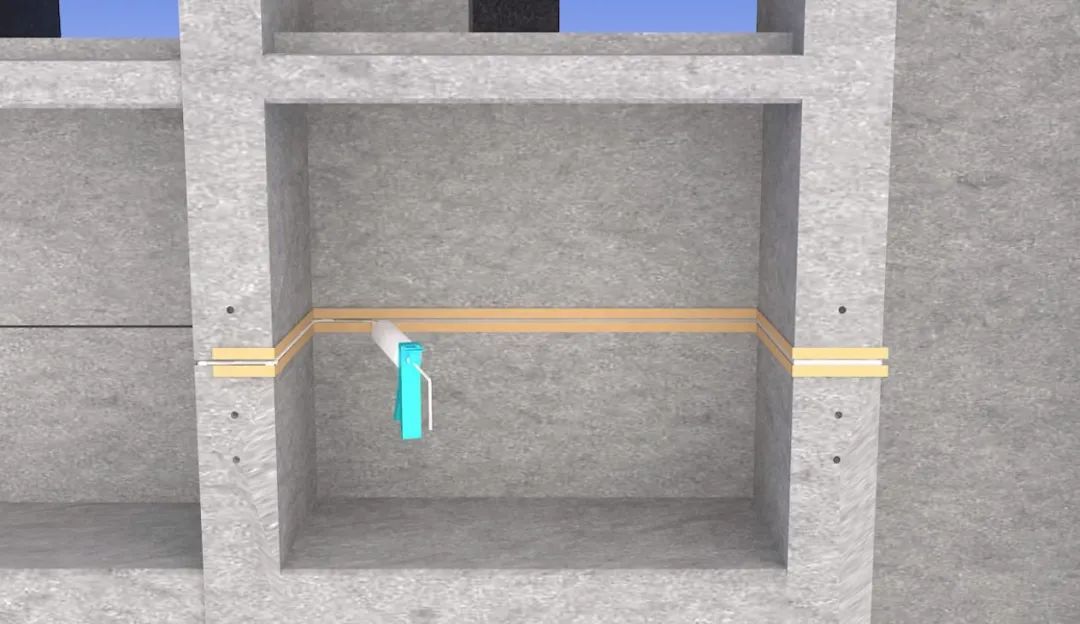

6、 The specific construction process animation of precast light partition wall installation is shown in video VII.

The total area of the project is 11841.15 square meters, The total building area is 75728.65 square meters, of which the prefabrication rate of standard floor of 1 tower is 18.46%, the assembly rate of standard floor is 56.50%, the prefabrication rate of standard floor of 2 towers is 16.99%, the assembly rate of standard floor is 55.10%, the prefabrication rate of standard floor of 3 towers is 16.99%, the assembly rate of standard floor is 55.10%, the prefabrication rate of standard floor of 4 towers is 16.85%, and the assembly rate of standard floor is 54.80%, The prefabrication rate and assembly rate of each building meet the requirements of prefabrication rate and assembly rate of precast buildings in Shenzhen.

After the formwork is installed and reinforced, the balcony laminated plate is hoisted.

4、 The construction technology introduction introduces in detail the types of precast components, the installation of precast stairs, the installation of precast bay windows, the installation of precast exterior wall panels with air conditioning panels, the installation of precast balconies and other construction technology animation.

See video for detailed construction process animation.

2、 General layout of the construction site: three PC yards are set up in the project, and the storage capacity of each yard is the demand of precast components in the corresponding area.

More wonderful 1 The use of Bim in precast architectural design 2 Full coverage of “lifelong responsibility system” in the construction industry! Detailed rules for punishment of the subject of five party responsibility! 3.

1 project) project applies the core value of BIM 5 [BIM policy] notice on printing and distributing the reference basis for pricing the application cost of building information model (BIM) technology in Guangxi Zhuang Autonomous Region (Trial) (GUI Jian Biao [2019] No.

Visual technical disclosure based on BIM model I animation of special disclosure scheme for roof waterproof construction 4 Xiaomi Wuhan headquarters (Donghu No.

3、 The components of the project are produced by Shenzhen Qianhai Shengde Construction Technology Co., Ltd.

2 contact us address: Wuhan BIM project consultation: 13114392301bim online technical training website: http://xrh.bimoem.com/ Email: 1057742089@qq.com Wechat: 1057742089..

The construction route of the project drives from Yanhe East Road to Jingsheng Road, Shengye road and Gongye first road, and then drives away from Yanhe East road.