Appreciation of bim+ precast cases in Dejian precast Industrial Park

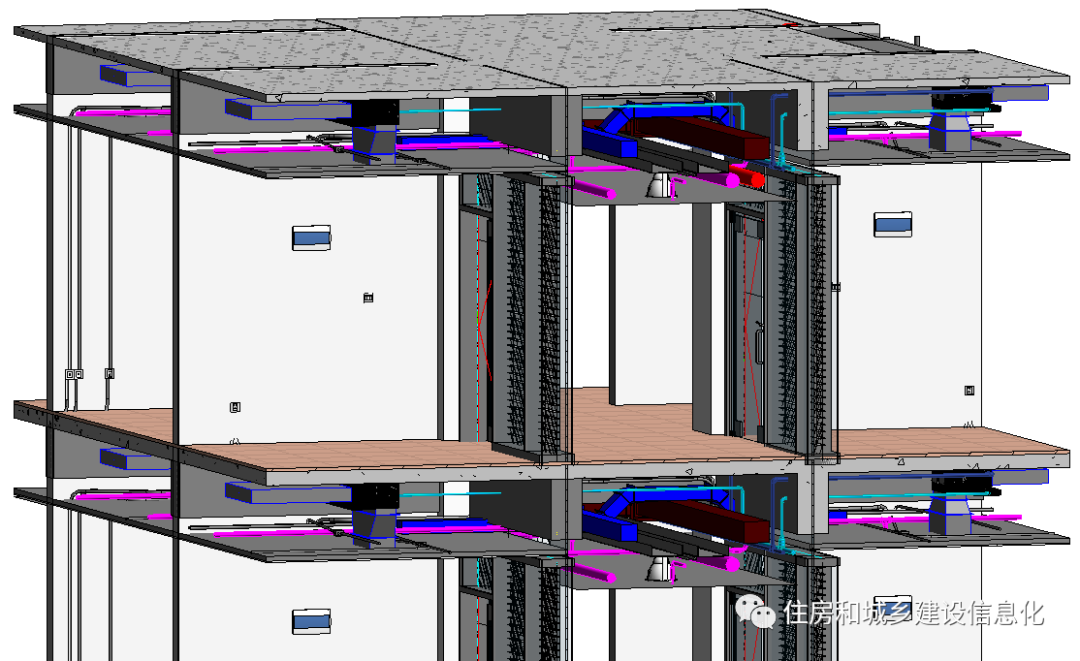

Compared with traditional buildings, precast buildings need to consider the coordination and cooperation between different disciplines in advance in design, so as to avoid problems such as punching holes in precast components in the later stage.

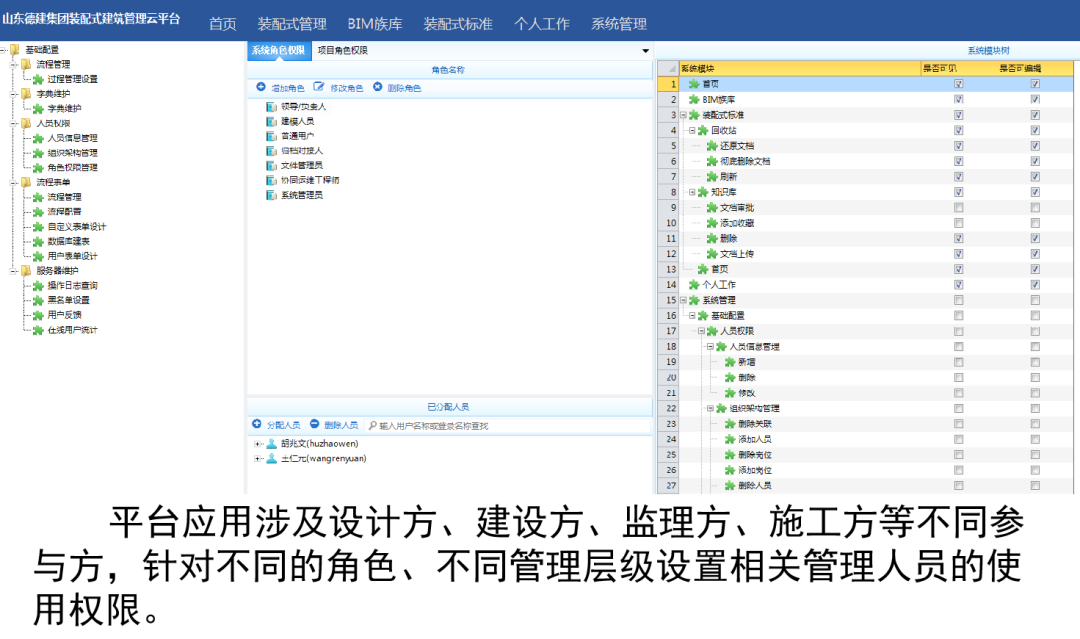

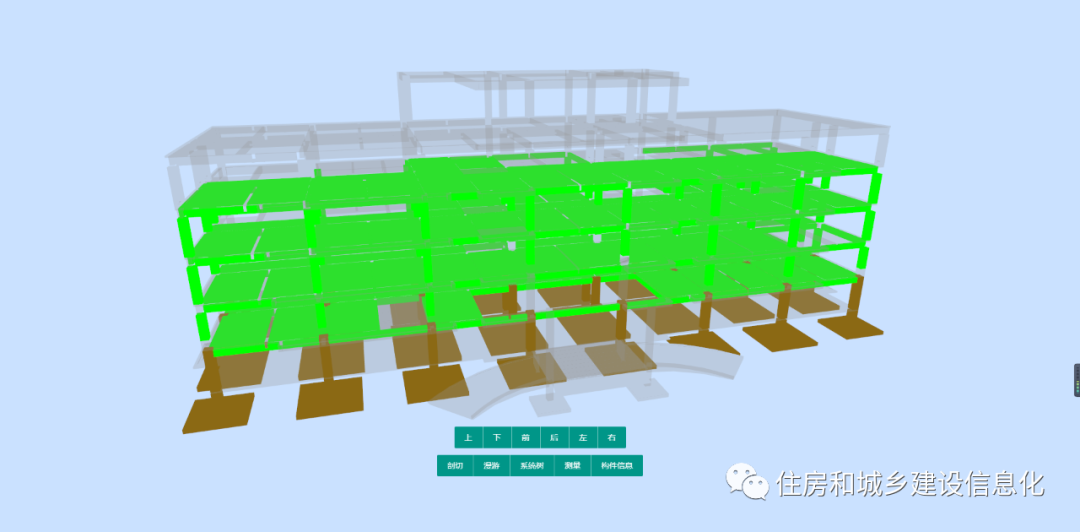

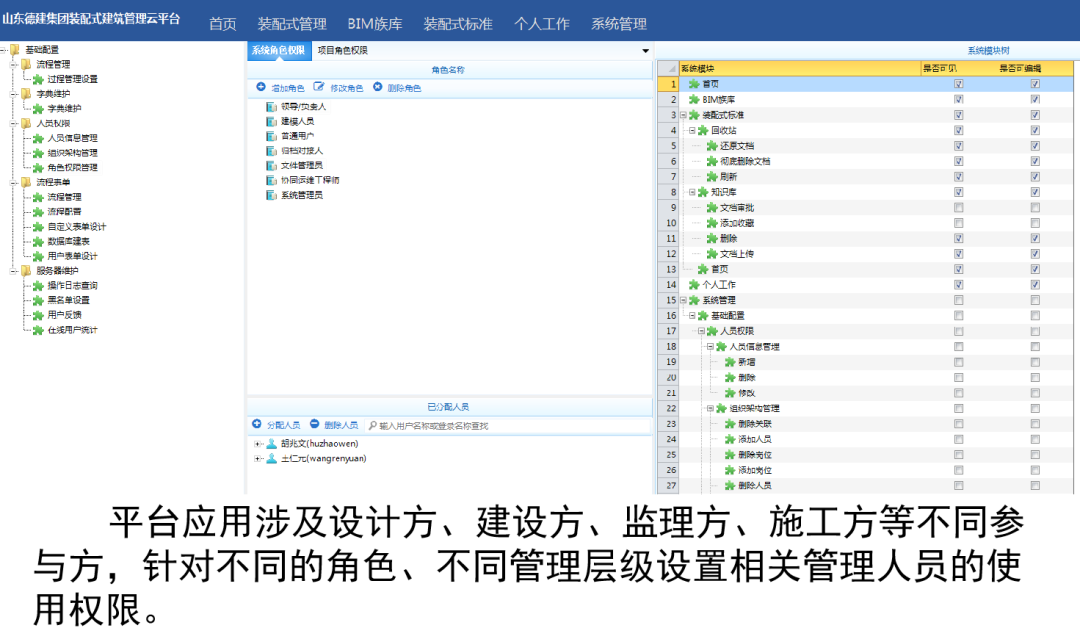

In this chain, the BIM system coordinates the design The relationship between manufacturing and installation makes production continuous, building components standardized and specialized, processing integrated, and Engineering Construction organized, so as to realize the integration of precast building production organization.

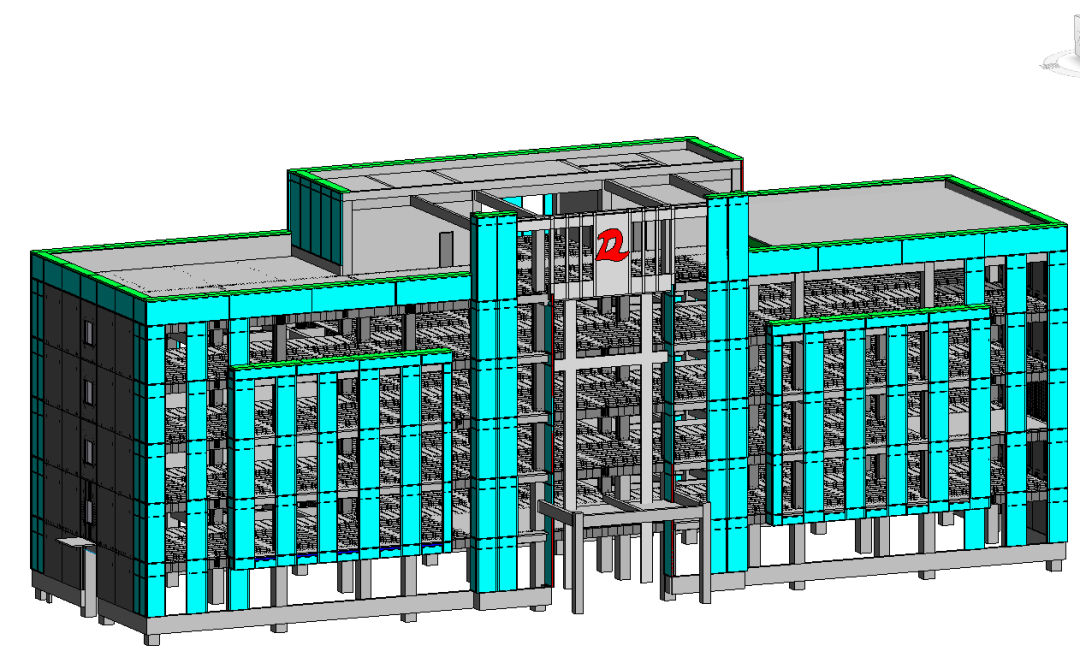

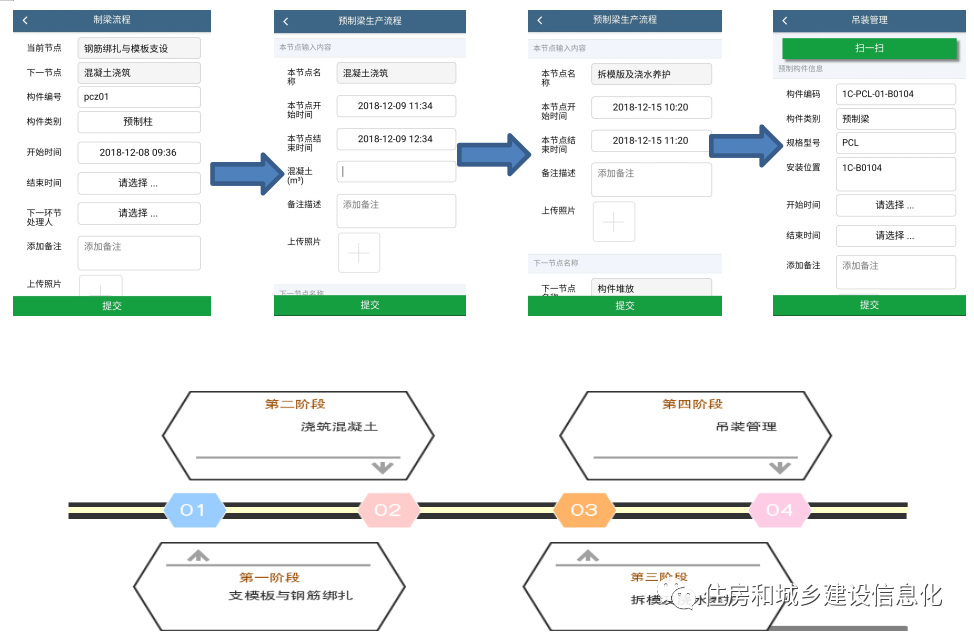

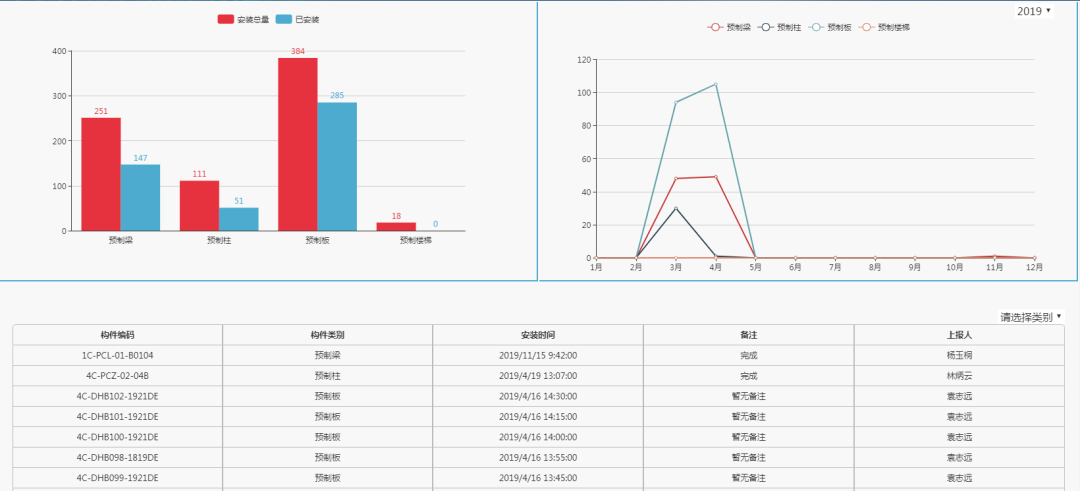

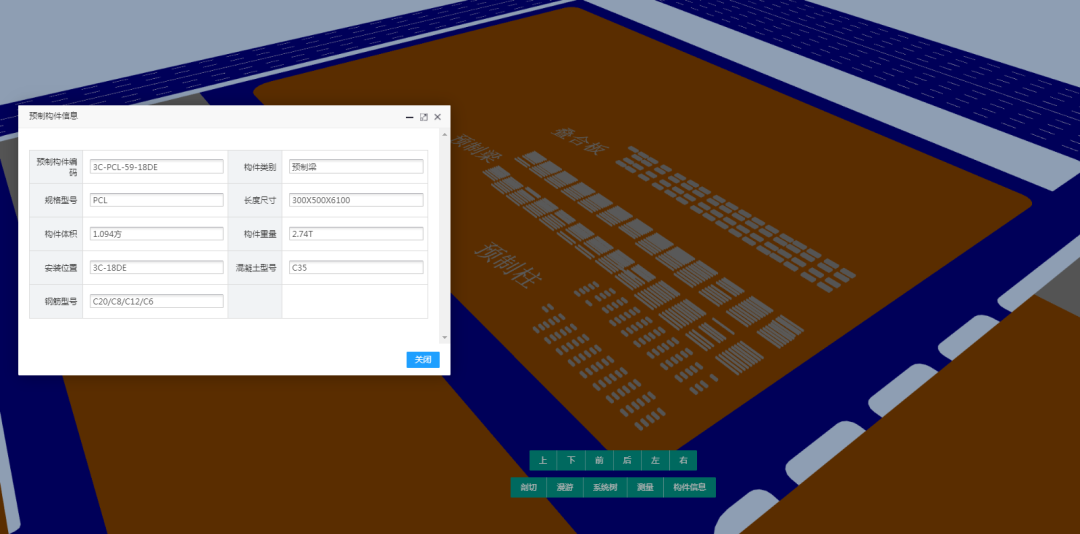

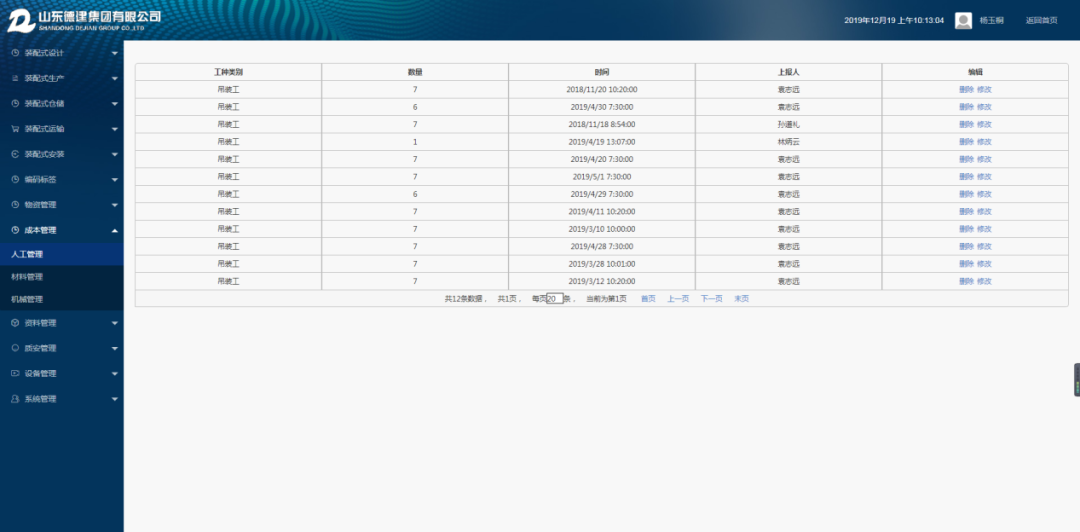

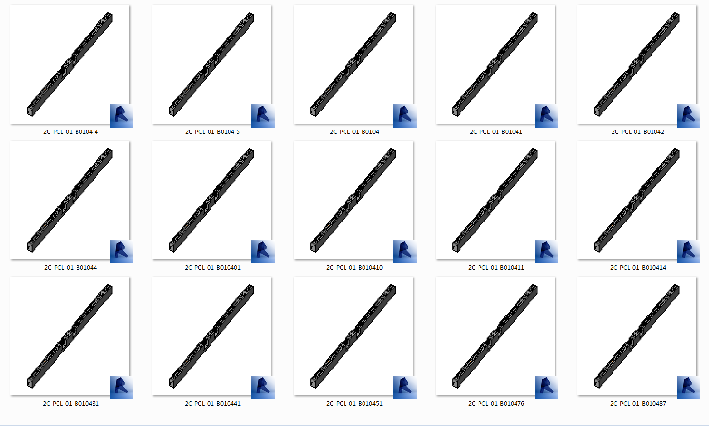

In Revit, the parameters of each precast component are refined, and the component code information is added to guide the later management and use the BIM model to connect with the construction management cloud platform.

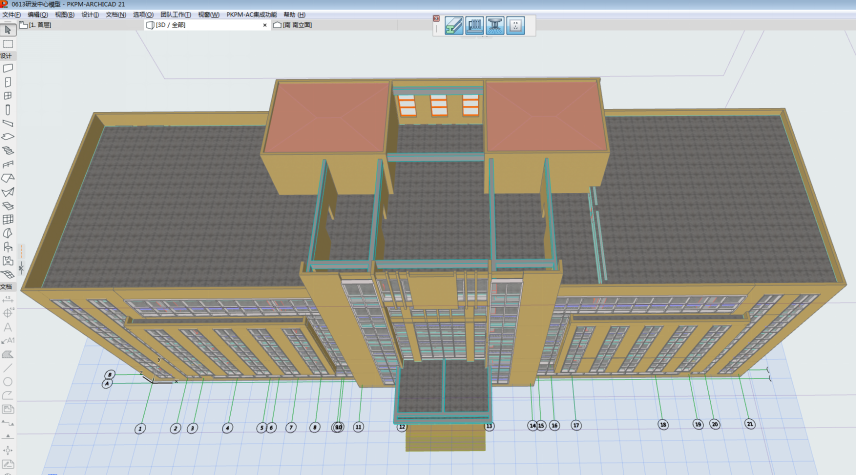

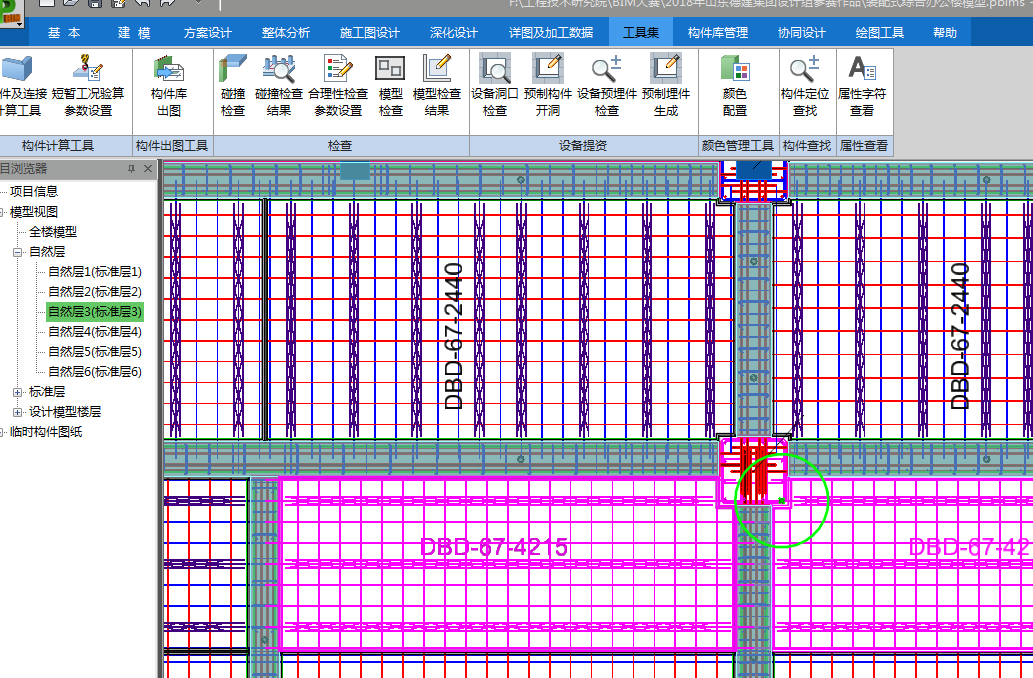

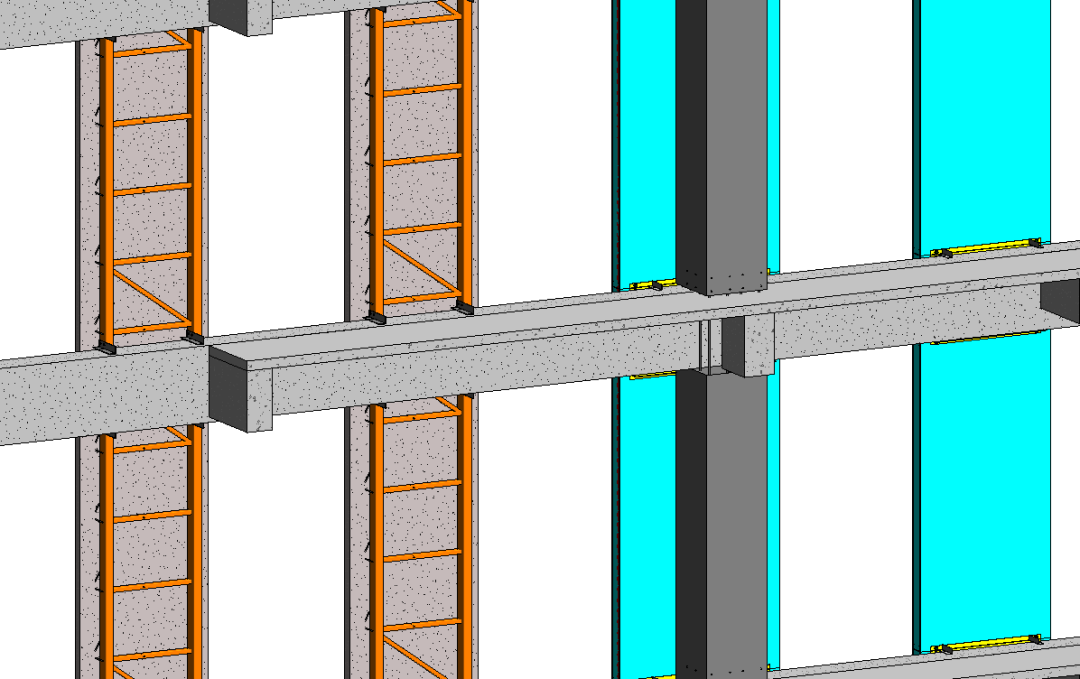

In the process of deepening the design of precast components, PKPM software is used for collaborative design among different disciplines to timely determine the reserved and embedded positions of beam openings and embedded parts.

Based on the above situation, we need to use BIM Technology in the precast Industrial Park office building project.

With the support of BIM Technology, the precast building realizes the efficient mode of the whole industry chain from design to factory production to final construction and installation.

Make the accuracy of the external hanging plate model reach lod500..

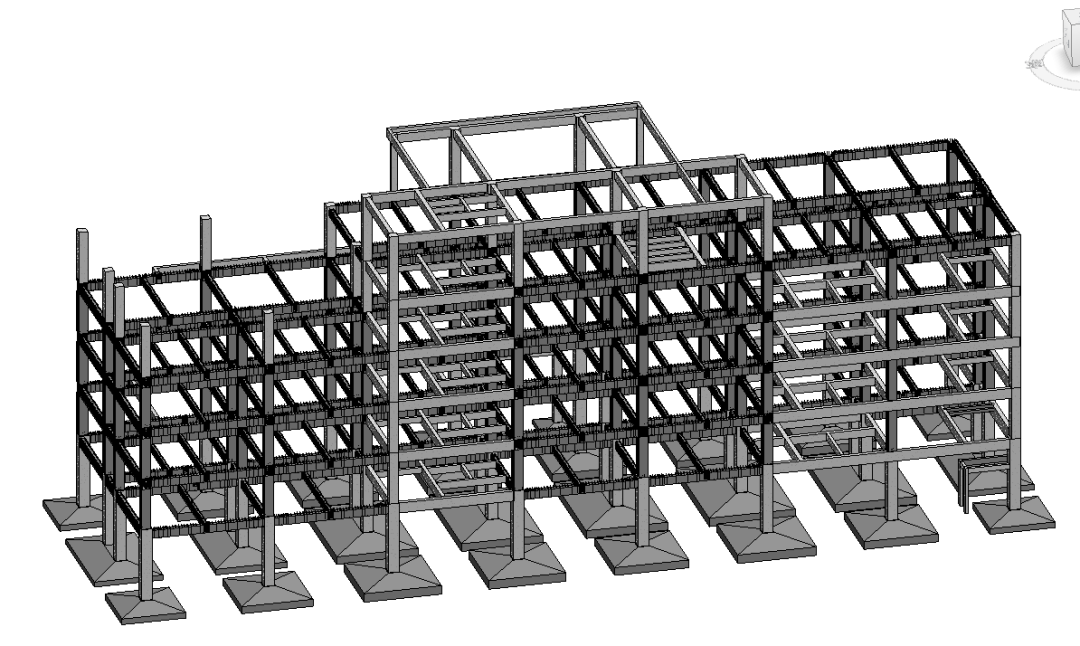

In order to realize the principle of “one time modeling, many times using”, the full discipline collaborative design model of precast component steel bar collision information precast Industrial Park office building uses plug-ins to export the PKPM model to IFC format and import it into Revit to convert it into RVT format, so as to facilitate the refinement and management of the model in the later construction stage.

The office building project of Dodd Construction Group’s Precast Industrial Park has a high assembly rate, and the number of precast components is up to more than 800.

At the same time, the company is faced with the problems of relatively lack of experience in construction management of dress matching buildings and incomplete construction quota related to precast buildings.

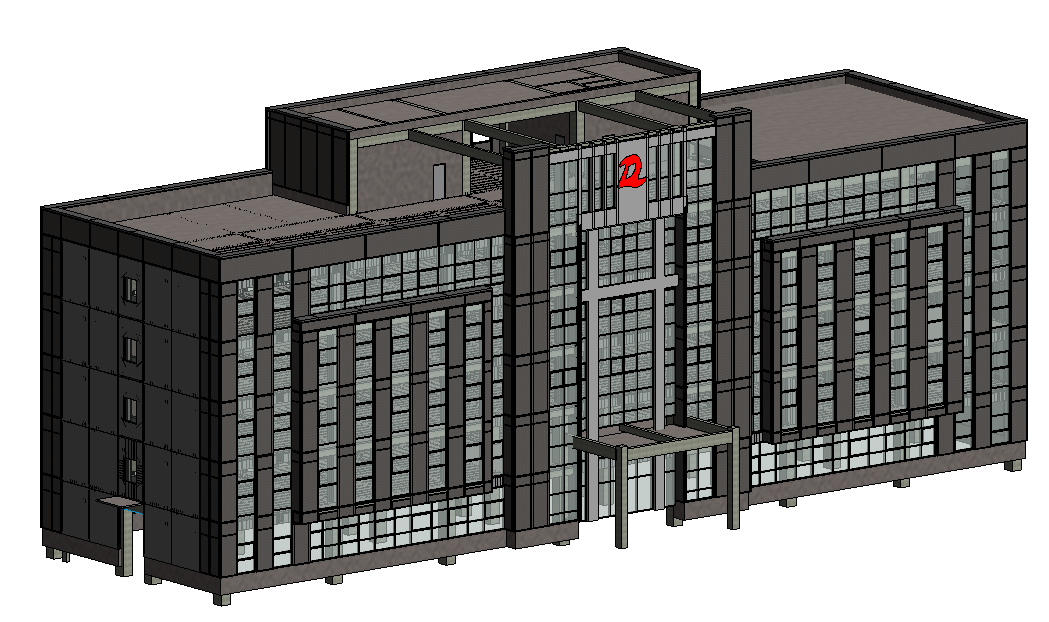

The precast office building has a construction area of more than 5200 square meters, and the assembly rate reaches 85.1%.

As a benchmark project of the group’s assembly construction, it is required to ensure the safety and quality of the project.

The project adopts the EPC mode.

The project adopts the EPC general contracting mode.

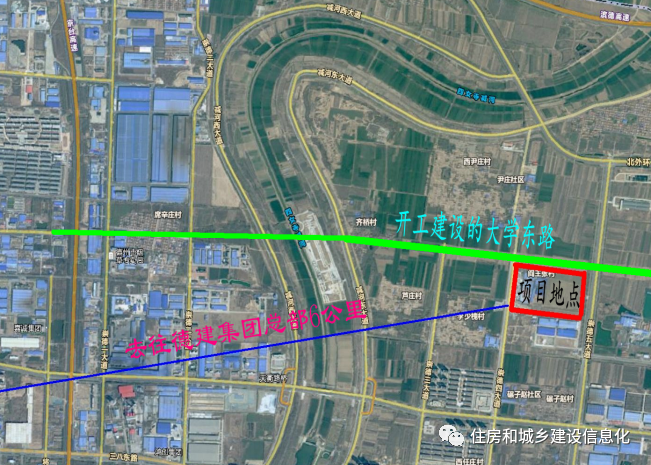

The precast office building project is located in the office area at the southwest corner of the industrial park.

The connection methods between various types of external wall hanging plates and the main structure are different.

As the relevant quota of precast construction is not yet perfect, the project contract adopts the method of cost plus remuneration.

During the design process, it is necessary to deepen the design of precast columns, beams and other components of the frame structure, in order to avoid the collision between different precast components and the collision between precast components and electromechanical equipment.

Among them, beams, columns, stairs and external wall hanging plates are precast components.

Through the collision inspection between multiple disciplines and the dynamic simulation of the construction process, the poor interaction of information in the whole process can be effectively avoided.

Avoid rework and on-site drilling in the later stage.

III Application of BIM Technology in precast building construction 1 BIM is applied in the design phase of the office building project of the precast Industrial Park.

It is a precast concrete frame structure building with the highest assembly rate and the largest building area in Shandong Province, and has been rated as a key demonstration project of precast buildings in Shandong Province.

Revit software and pkpm-bim design platform are used to realize the integrated design of the structural system, peripheral protection system, equipment pipeline system and interior decoration system of the precast building, ensuring the mutual coordination among the disciplines of architecture, structure, water supply and drainage, HVAC, electrical and intelligence.

2.

By applying BIM Technology to the whole process of design and construction of precast buildings, the accuracy of information transmission in design and construction can be fully guaranteed, and the exquisite construction of precast buildings can be realized.

Click the blue word to pay attention to our recent years.

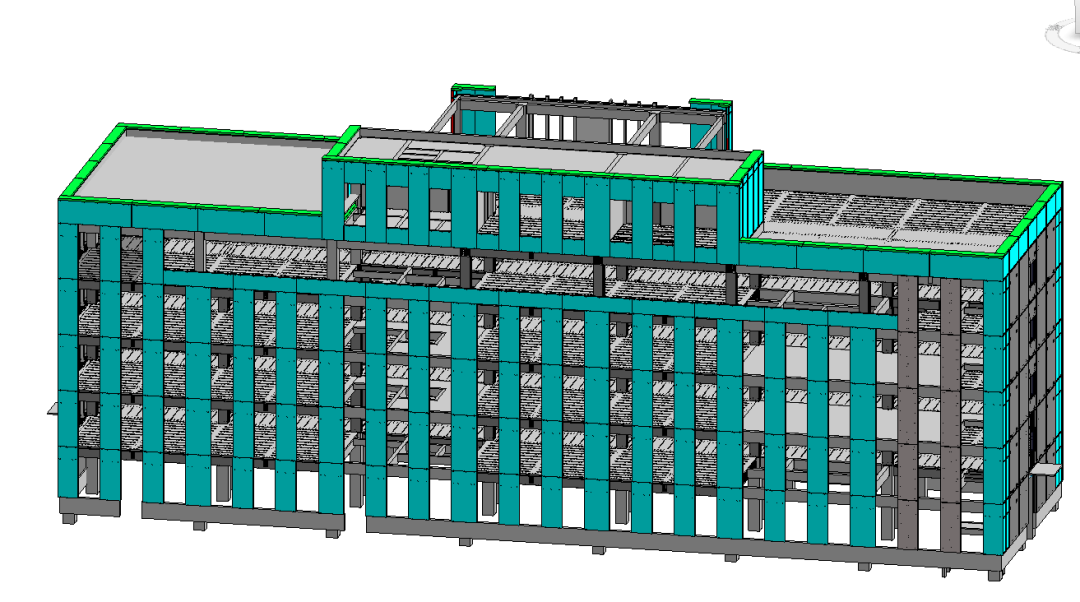

Building model drawing of PKPM precast Industrial Park office building this project adopts a frame structure, and the main structure is precast columns and beams.

As one of the important directions for the development of the national construction industry in the future, the precast building mainly has four characteristics: the first is the standardization of architectural design, the second is the modularization of functional space, the third is the industrialization of production activities, and the fourth is the assembly of on-site operations.

The terrain is flat and the traffic is convenient.

I Project information Dejian assembly industrial park is located in Dezhou Economic Development Zone, adjacent to Chongde Fourth Avenue in the west, Daxue East Road in the north, Chongde Fifth Avenue in the East, and Runde technology company in the south.

In order to avoid collision and rework in the later stage, fine modeling is carried out for each external wall hanging plate and structure body in advance, and independent modeling is carried out for a single external wall hanging plate to form an external wall hanging plate component library.

Shandong Dejian group, as the general contractor, independently completes the project design, material procurement, component production, on-site assembly and other construction processes.

the project construction management is difficult.

Due to the limitation of construction period and site, precast components are processed and cured on site.

Location of the office building project in the precast Industrial Park of Dejian group effect drawing of the office building project in the precast Industrial Park of Dejian group construction drawing of the office building in the precast Industrial Park of Dejian group BIM model drawing II Difficulties in project construction 1 The assembly rate of the project is high, and the type of precast components is high.

BIM model of precast Industrial Park structure the peripheral protection system of the project adopts the combination of curtain wall and precast external wall hanging plate, of which the number of external wall hanging plates is up to more than 150, including three types: GRC external wall hanging plate, concrete sandwich insulation plate and steel frame thermal insulation light plate.

The types of components include precast laminated plates, precast columns, precast beams, precast stairs, precast exterior wall panels and so on.

In the design stage of the project, the following construction problems, such as the processing and installation of precast components, can be considered.

The design, construction and procurement of the project are all completed by Dejian group, which is a great test for the company’s management ability.

In construction, the requirements for construction accuracy are high, so it is necessary to avoid ‘mistakes, omissions, collisions and defects’ in the installation of precast components.

It is difficult to accurately transfer the location and size information of components.