Assembly type you don’t understand, I teach you, stupid!

It is the fundamental transformation of the mode of construction production from extensive production to intensive production.

Assembly is not just “lapping”.

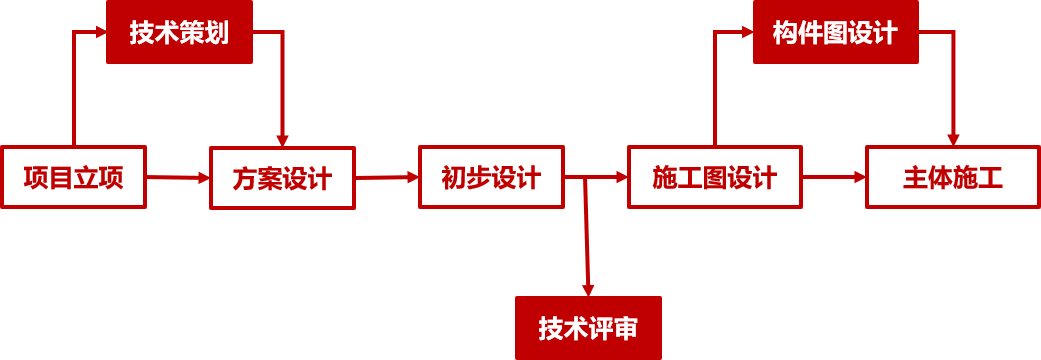

Key points of precast design 04 analysis of precast costs 01 overview of precast buildings.

01 overview of precast buildings 02 interpretation of precast policies 03.

Second, the trend of construction industry and industrialization.

Therefore, this industrialized and industrialized building has been widely used in Europe, America, Japan and other countries and regions.

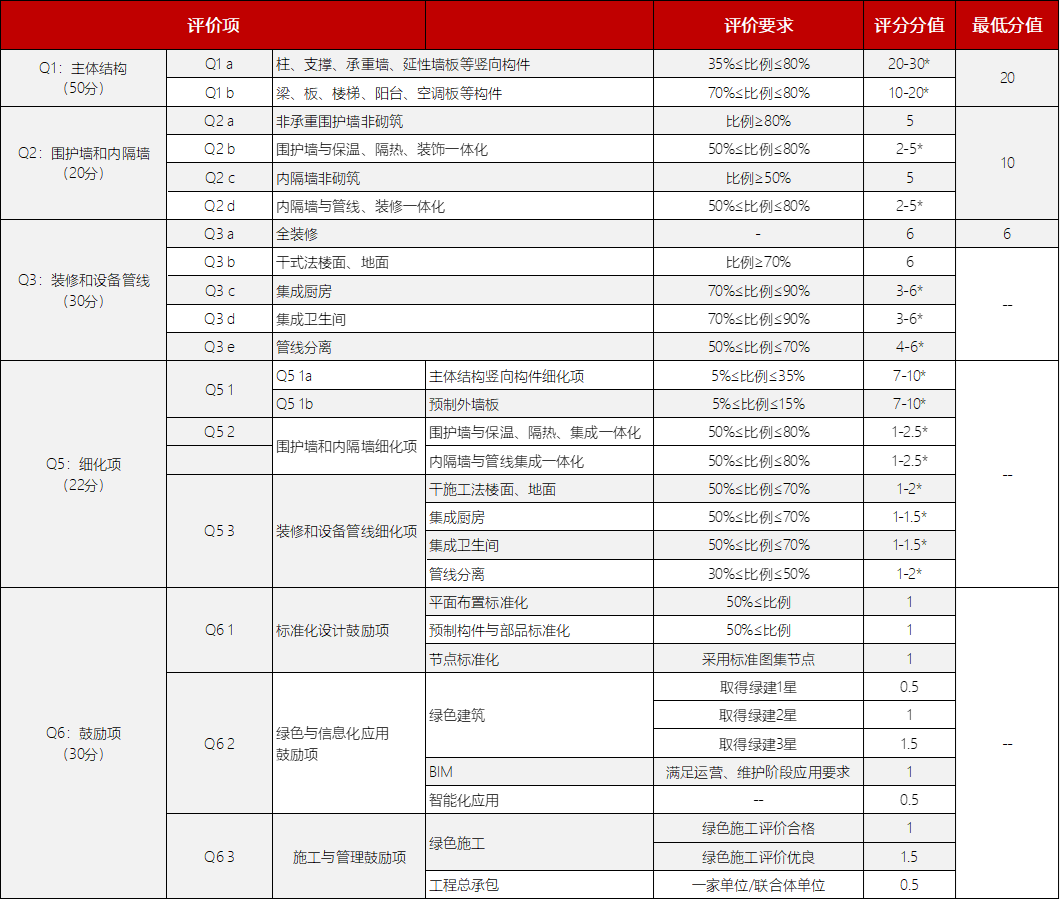

Due to the different policy requirements for precast buildings across the country, the author mainly analyzes the policy interpretation of precast buildings in combination with the relevant policies of the state and Guangdong Province — the national policy on precast buildings is mainly based on the evaluation standard for precast buildings (GB / t51129-2017).

02 interpretation of precast policy in terms of precast buildings in China, the planning of precast buildings has been intensively issued since 2015: the evaluation standard for industrialized buildings was issued at the end of 2015, which decided to comprehensively promote precast buildings in 2016 and made a breakthrough; On November 14, 2015, the Ministry of housing and urban rural development issued the outline for the modernization development of the construction industry.

With the development of modern industrial technology, building houses can be manufactured in batches and complete sets like machine production.

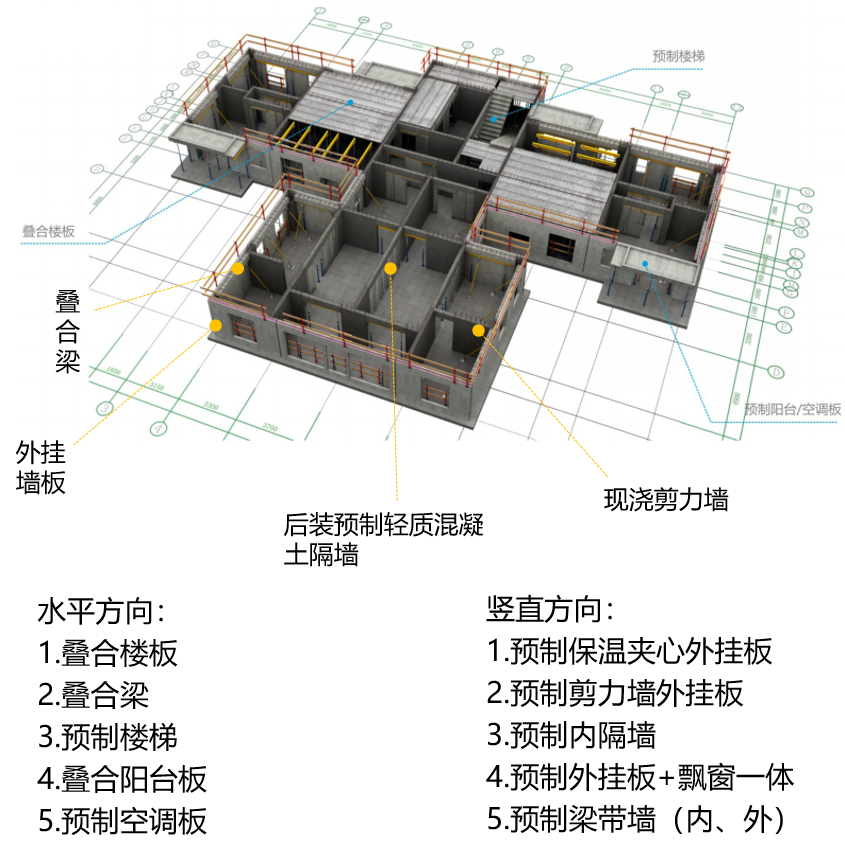

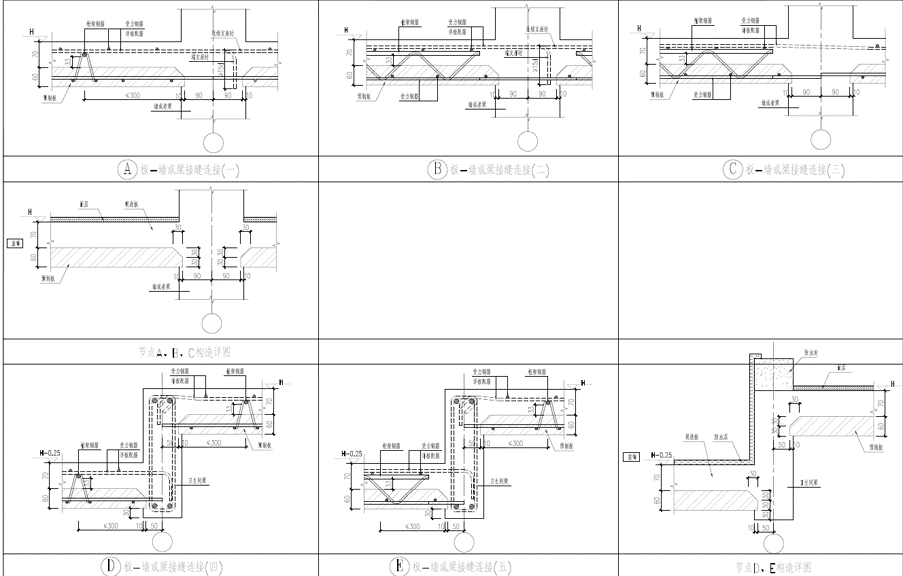

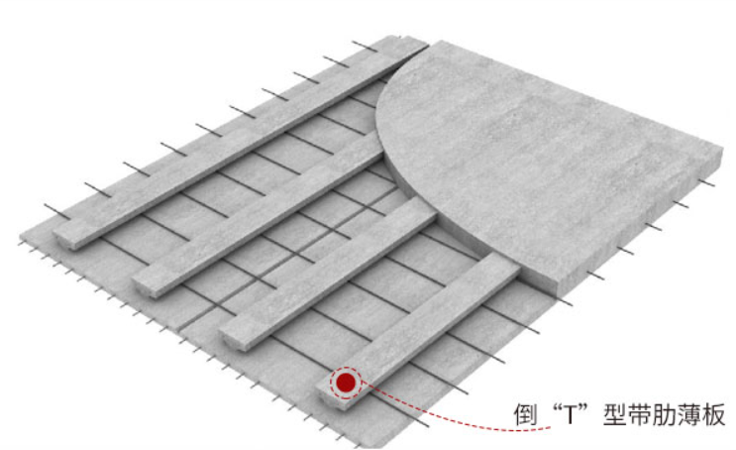

The definition of precast buildings: buildings assembled by precast parts on the construction site; Definition of assembly rate: the comprehensive proportion of precast components used in the main structure, enclosure wall, internal partition wall, decoration and equipment pipeline within the scope of building evaluation (above the outdoor floor)..

First, The trend of energy conservation and environmental protection precast buildings well respond to the requirements of national energy conservation and environmental protection.

As long as the precast building components are transported to the construction site, we can imagine the pre prepared components such as beams, plates, columns and walls as Lego blocks, which only need to be put together at the construction site.

Today, I’d like to share with you the analysis outline of precast buildings from the perspective of Party A.

Building a house is more and more like building a car.

The emergence and development of precast buildings have their inevitability.

This is the precast building.

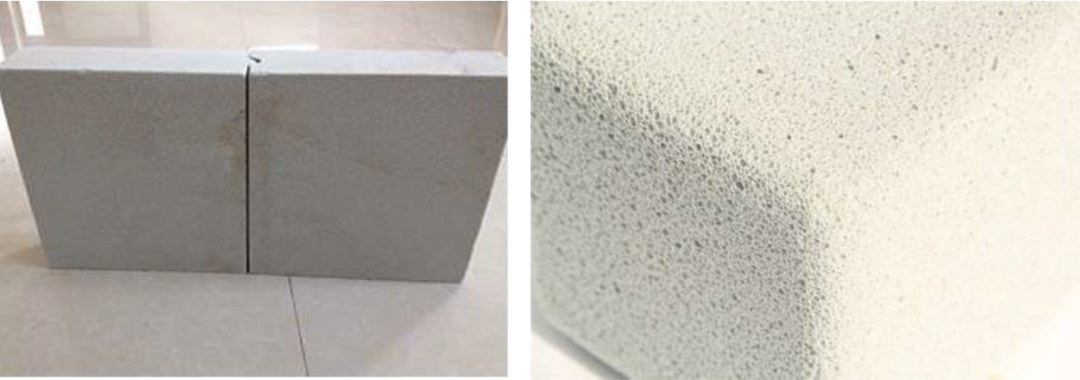

After the precast components are transported to the construction site, the lapping and pouring of reinforced concrete will be carried out to ensure the safety of the assembly room.

The main components of precast buildings are manufactured in the component processing plant and transported to the project site for assembly, which not only continuously reduces the consumption of cement, sand, stone and steel through the industrial production mode, but also reduces the environmental pollution on the construction site.

Construction industry and industrialization use modern management mode to realize the generalization of building components and the assembly and mechanization of on-site construction through standardized architectural design and modular and industrialized part production.

It is planned that precast buildings will account for more than 20% of new buildings by 2020 and more than 50% of new buildings by 2025; On February 22, 2016, the State Council issued the guidance on vigorously developing precast buildings, which requires that precast buildings such as precast concrete structure, steel structure and modern wood structure should be developed according to local conditions, and strive to make the proportion of precast buildings in the area of new buildings reach 30% in about 10 years; On March 5, 2016, the government work report proposed to vigorously develop steel structures and precast buildings and improve the standards and quality of construction projects; On July 5, 2016, the Ministry of housing and urban rural development issued the list of precast building science and technology demonstration projects planned by the Ministry of housing and urban rural development in 2016, and published the list of precast building science and technology demonstration projects of science and technology projects in 2016; On September 14, 2016, the State Council held an executive meeting of the State Council, which proposed to vigorously develop precast buildings and promote the adjustment and upgrading of industrial structure; On September 27, 2016, the State Council issued the guidance of the general office of the State Council on vigorously developing precast buildings, which defined the key areas of vigorously developing precast buildings and steel structures, the proportion of precast buildings in the future, the new building objectives and key cities.

At the same time, many components can be reused, It also reduces the possibility of secondary waste pollution.

There are two main development trends that have led to the promotion of precast buildings across the country.

Like Toledo, precast buildings precast some or all components in the factory, and then transported to the construction site for assembly.