Combined application of precast building and BIM technology

9.

Combined with the characteristics of precast buildings, the precast components and cast-in-place components can be classified and counted based on the BIM model, through which the design schemes can be quickly compared and selected, and the preliminary cost control in the scheme planning stage can be achieved.

The advantages of the combination of the Internet and BIM are that the information is accurate and rich, the transmission speed is fast, and the errors that may be caused by manual input of information are reduced.

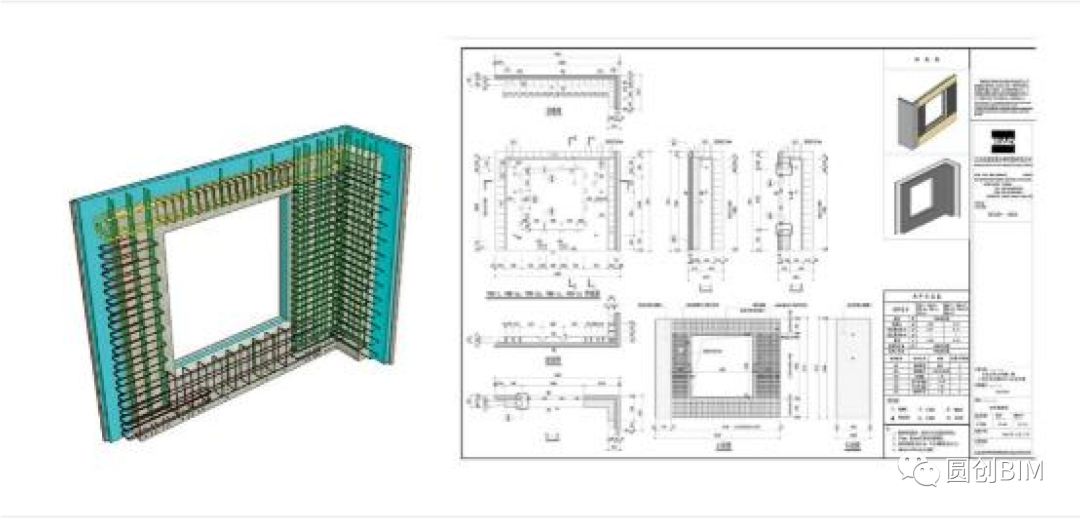

After preliminary proofreading, review and collision check, the corresponding drawings, such as plan, elevation, section, etc., are created in Revit, and the drawings are checked again in 2D drawings.

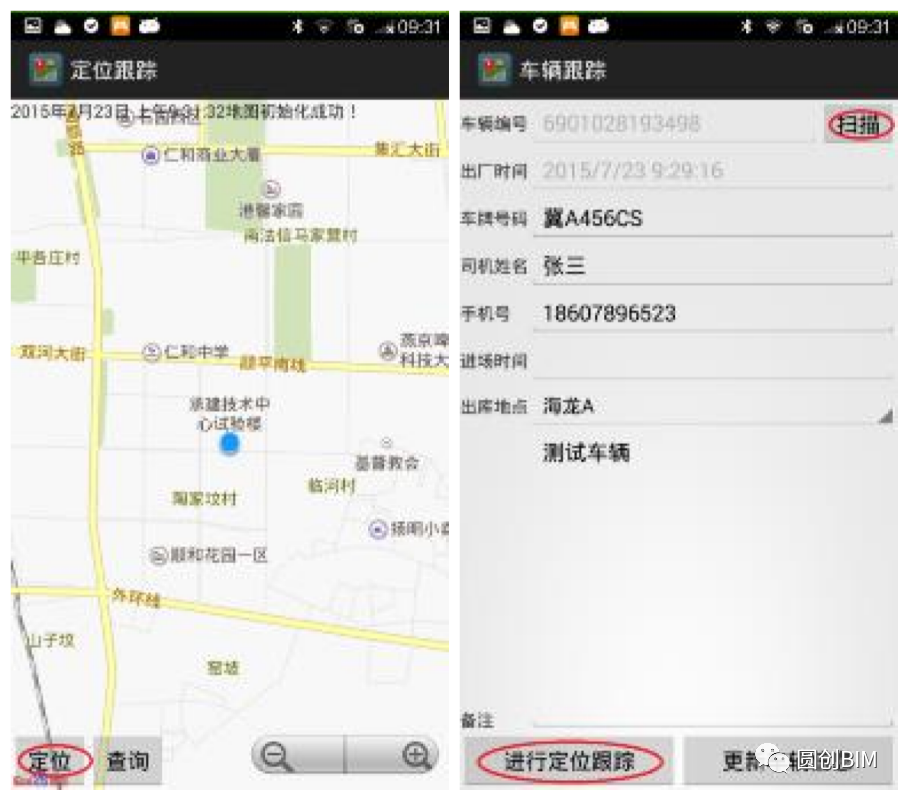

2、 The application of BIM technology in the component transportation stage can use RFID technology to track and monitor the delivery, transportation, mobilization and installation of components, and transmit information instantly via wireless network.

The model is integrated on the basis of each BIM sub model, integrating the building and electromechanical model to form a single-layer integrated model and the model of the whole building.

The operation process is as follows: 1.

Collision inspection: Based on the BIM integrated model, conduct collision inspection on the interior of precast components, between precast components and electromechanical and precast components, and solve the collision problem in the design phase.

Through dynamic management, it can well assist on-site construction and effectively improve the rationality and accuracy of precast component design, which is convenient for later maintenance.

Finally, recheck the detected collision.

Building performance analysis can use the parametric characteristics of BIM model to establish a calculation model for building performance analysis.

Compared with the cast-in-place construction method, the precast RC structure is conducive to green construction, because the precast construction can better meet the requirements of green construction in terms of land saving, energy saving, material saving, water saving and environmental protection, reduce the negative impact on the environment, including noise reduction, dust prevention, environmental pollution reduction, clean transportation, site interference reduction, water, electricity, materials and other resources and energy conservation, and follow the principle of sustainable development.

8.

In addition, precast structures reduce construction waste to a large extent (accounting for 30% – 40% of the total amount of urban waste), such as waste reinforcement, waste iron wire, waste bamboo wood, waste concrete, etc.

7.

In fact, the correct approach is to intervene professionally in the early planning stage, determine the technical route and industrialization goal of precast buildings, and create the scheme according to the established goal and the principle of component separation in the scheme design stage.

5.

After checking, CAD or PDF drawings can be generated.

BIM technology can be used in the whole process of design, production, transportation, installation, operation and maintenance of precast buildings.

4.

Moreover, the cast structure can continuously complete multiple or all processes of the project in sequence, so as to reduce the type and quantity of engineering machinery entering the site, eliminate the idle time for process connection, realize the vertical cross operation, reduce the number of construction personnel, thus improving the work efficiency, reducing material consumption, reducing environmental pollution, and providing guarantee for green construction.

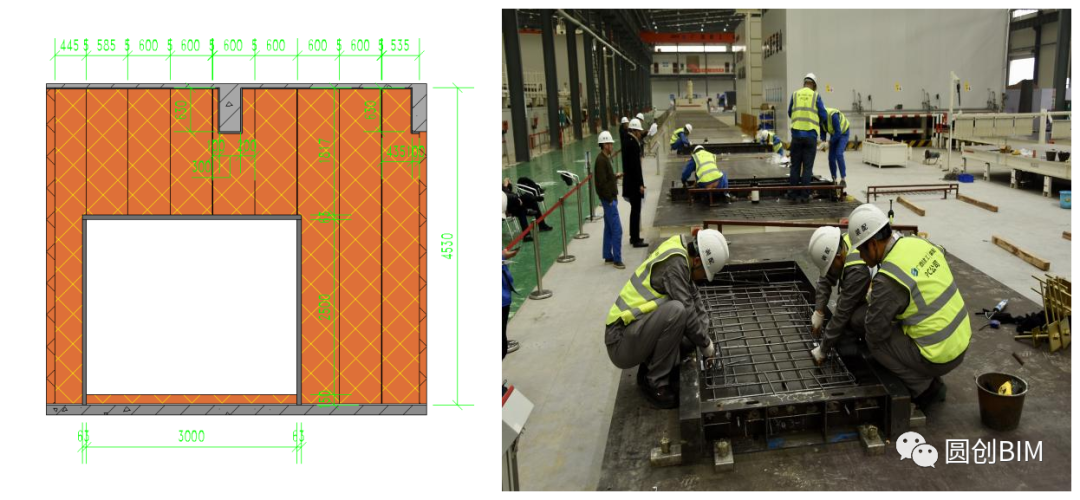

The main building components are precast in the factory.

2.

In the traditional way of BIM component splitting and optimization design, most of the components are split by the component factory after the construction drawings are completed.

It is conducive to the development of building industrialization in China, improving production efficiency, saving energy, developing green and environment-friendly buildings, and is conducive to improving and ensuring the quality of construction projects.

After the collision check is completed, the component model is adjusted, the view and material list are created, and the detailed design drawing of the component is finally generated.

Components and cast-in-place models are refined to the depth of reinforcement, and electromechanical models are refined to the end depth of sockets.

The project participants can intuitively grasp the logistics and installation progress information of precast components through the Internet based construction management platform..

6.

Generally speaking, precast buildings are like “building blocks”.

Modeling uses the modeling function of the software to establish the BIM model of the project.

3.

Fabricated buildings have become the mainstream development trend in China’s modern industry.

1、 The application of BIM technology in the design stage and component production standardization Precast precast buildings are different from ordinary forms of buildings.

Because of its special nature of construction, it has obvious advantages in construction projects.

Some or the whole components of the building are precast in the factory in advance and then transported to the construction site for assembly and splicing through corresponding connection methods; Therefore, precast buildings are characterized by good timeliness, low production and construction costs, less construction waste, flexible construction, safer operation, high quality and accuracy.

The quality and specification of such mass produced building components are controllable; Therefore, it is necessary to control the quality from the design stage.

The Internet based precast building construction management platform can collect and track the information about the delivery, transportation, mobilization and installation of precast components through RFID technology and GIS technology, and transmit real-time information through the Internet and the BIM model on the cloud platform.

Here is a brief introduction to the combined application of precast buildings and BIM technology.

It is one of the important directions of building structure development in China.

The information responds in the BIM model on the cloud platform in a set way, so as to implement the quality and progress tracking management of component construction.

Fabricated building is a building assembled by precast components on the construction site.

The BIM technology is used to visualize and parameterize the information of the components, and the splitting is carried out on the basis of the three-dimensional design model, which can accurately count the size, volume and weight of the embedded parts, facilitate the accurate design of the components, and more effectively avoid design mistakes.

Precast precast buildings are constructed in an industrialized production mode.

For rebar embedded collision check, set collision ignore rules as required, modify collision types and parameters, select collision objects, and then run collision check.

The economic calculation analysis is divided into precast components and cast-in-place components according to the composition and pricing principles of precast buildings.