Detailed explanation of PC construction process of precast high-rise residential building

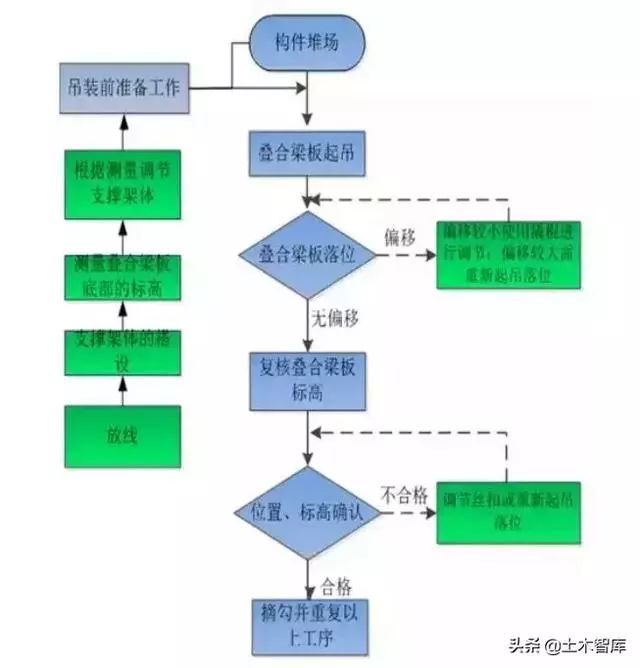

The wallboard shall be placed vertically, and the support meeting the stiffness requirements shall be made of channel steel.

Flexible materials can be used for supporting points, which shall be temporarily fixed after stacking, and temporary enclosure measures shall be taken for the site.

Off site preparation.

Vertical transportation shall be considered for PC structure transportation, storage yard and finished product protection transportation, because it can not only avoid unnecessary damage, but also avoid the difficulty of later construction.

When placing, a full-length wooden strip shall be set at the bottom of the component and fixed with the transport vehicle with a tight rope.

When turning and changing lanes, it should slow down to prevent the wallboard from overturning.

Preparation inside and outside the site 1.

2.

When transporting the wallboard, the vehicle starts slowly and the speed should be uniform.

If the transport vehicle passes through the roof of the underground garage, the bottom of the beam shall be supported and reinforced with 16# I-beam at the bottom to ensure that the static load weight of the underground garage meets the characteristics of PC transportation weight yard.

The rest of the surrounding construction roads of the basement are cast with 200 thick C20 concrete, in which the main roads on the non basement and the PC storage yard must be laid Φ 18@150 Single layer two-way reinforcement.

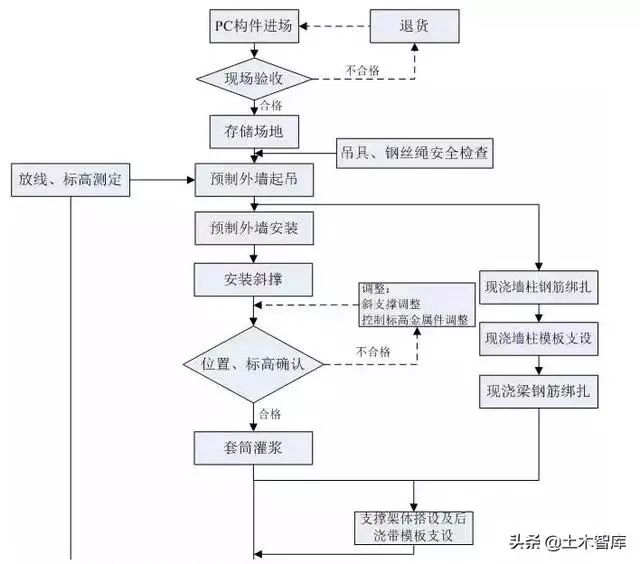

Communicate with PC manufacturers and PC structure related component manufacturers at any time, accurately understand the address of each PC structure manufacturer, and accurately predict the on-site distance between PC structure manufacturers and the project, so as to contact PC structure manufacturers more accurately and send PC structure time, which is conducive to the overall construction arrangement; Determine the type of PC structure produced by each manufacturer on the spot, investigate the production capacity of PC structure manufacturers on the spot, and make a reasonable overall construction plan and PC structure mobilization plan according to the actual situation of different manufacturers; After investigating each manufacturer, invite the PC structure manufacturer to the construction site to understand the situation, the transportation route of PC structure, and the width, thickness and corner of the road on site; Before the specific construction, our company and the supervision department shall send quality personnel to the PC structure manufacturer for quality acceptance, exclude the unqualified PC components from the on-site construction, carry out factory rectification for problematic PC components, and carry out factory repair for defective PC components.

The number of stacked blocks shall not exceed 6, the stacking height shall not exceed the height limit requirements, and the number of balcony boards and stair boards shall not exceed 3.

Due to man-made collision or tower crane mechanical collision and dumping, the PC in the storage yard collapsed in the form of donomi dominoes.

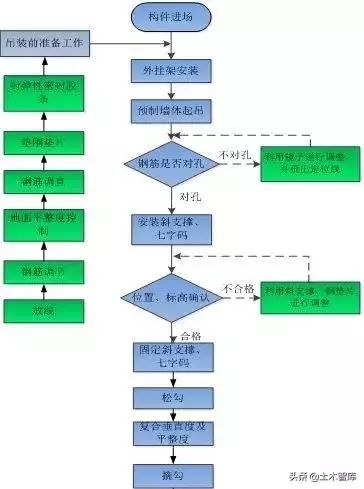

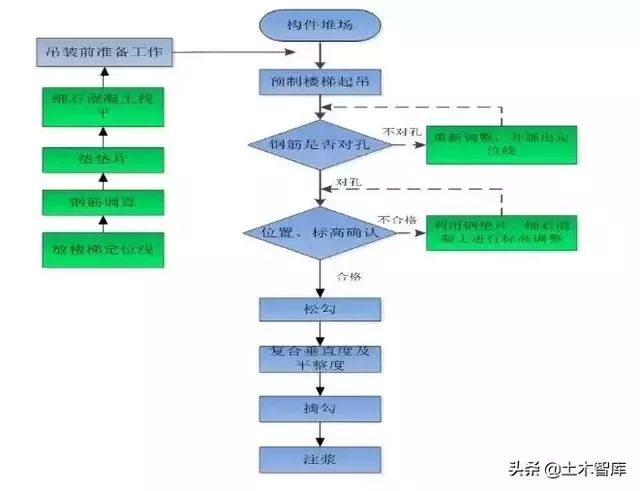

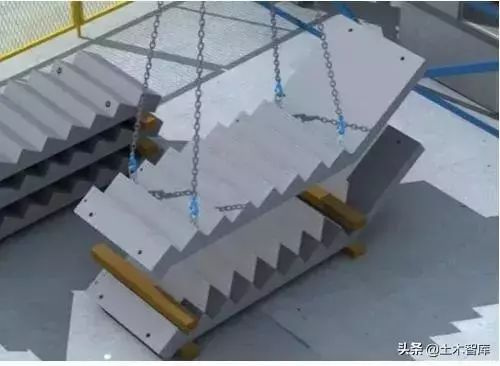

Precast PC concrete construction 1.

Cotton yarn or rubber block are used at the junction of PC structure and steel frame to ensure that the PC structure and steel frame are damaged due to collision in the process of transportation..

Prepare the construction site, make good preparations for “three supplies and one leveling”, road, water, electricity and the whole site, and build the yard preparation of on-site temporary facilities and PC structure; In order to meet the construction requirements of PC structure construction and the maximum weight of single component of PC structure, ensure that the hoisting distance of PC structure of each house is met, and according to the construction progress and site layout requirements, the project 1#~4# building is equipped with four stc7015 tower cranes, which are reasonably arranged near each house to ensure the average hoisting of nodes on the floor every 5 ~ 6 days.

Due to the heavy construction of PC in the project, it is difficult to protect the storage yard and transportation finished products.

When transporting precast components, the vehicle shall start slowly and the speed shall be uniform.

According to the requirements and combined with the actual situation, the basement roof within the scope of the vehicle road and PC storage yard shall be reinforced, especially the vehicle line shall be reinforced with steel pipes, and all bent steel pipes shall be removed after the structure is capped.

Selection of component units and production scope.

Schematic diagram of road making schematic diagram of on-site Road 2.

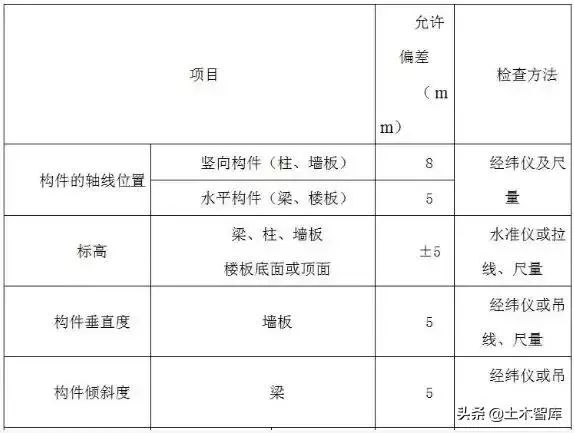

According to the form and quantity of components, it is divided into PC components such as precast exterior wall panels, precast stairs, balcony panels, convex window panels and equipment platforms.

The steel frame is used for auxiliary transportation in the process of transportation.

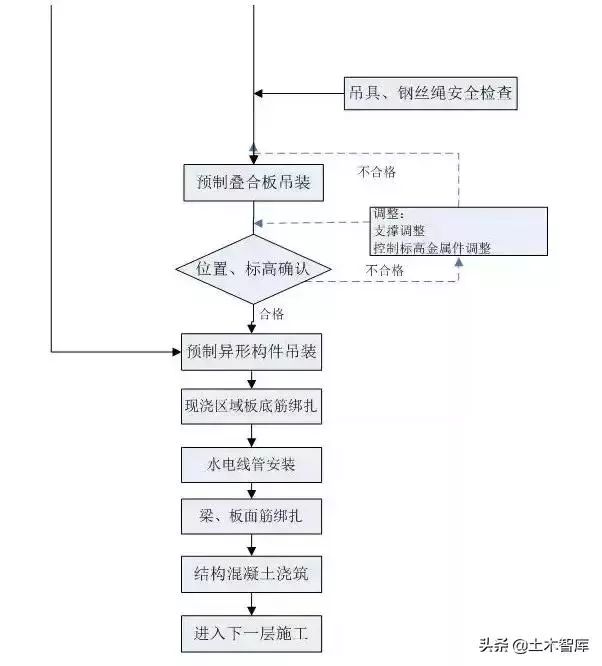

The storage yard is stacked staggered and orderly according to the hoisting sequence, and a certain interval is reserved between plates.

The PC structure of the project has many single layers and large weight.

Balconies and air-conditioning boards can be stacked for transportation.

According to the above construction requirements and the convenience of PC structure hoisting construction, the PC structure management team plans to set up a PC storage yard for each room.

Before loading, install the lifting frame, place the PC structure on the lifting frame, and then fix the PC structure and the frame together with soft isolation, Ensure that the PC structure will not be damaged unnecessarily during transportation.

Off site preparation.

The storage yard is the basement roof (using the fire lane, and there are reinforcement measures at the bottom).

After the precast structure is transported to the construction site, it shall be orderly lifted to the special stacking site by tower crane or truck crane according to the construction hoisting sequence.

The supporting points of wallboard shall be set at both ends of the bottom of wallboard, and the stacking site shall be flat and solid.

PC precast components shall be manufactured in factory, and professional precast component production units shall be selected; Fabricated precast components are processed in the factory and transported to the construction site for hoisting and installation by the general contractor.

As shown in the figure below: finished product protection measures must be taken for the PC structure of the project during transportation, stacking and hoisting.

PC balcony, PC air conditioning board, PC staircase and equipment platform shall be transported horizontally.

When turning and changing lanes, it shall slow down to prevent the wallboard from overturning.

Sleepers must be added to the components for the stacking of precast structures, and anti overturning measures shall be taken for the components on the site.

The reinforcement transport vehicle and PC storage yard must use the basement shift as the construction road and material storage yard.

The drawing shows that the PC structure of each room is about 4m long and weighs about 4.6t.

Some transportation lines cover the underground garage.

In order to ensure that the PC structure can enter the construction site and can be transported smoothly at the construction site, the road to the main gate of the site shall be at least 8m wide, and the road to the construction site shall be 5m wide, so as to ensure that the transportation vehicles of PC structure can pass in both directions on the main gate road, and ensure the smoothness of turning and straight walking at the construction site.