Eight series of precast buildings, leading the development of the industry!

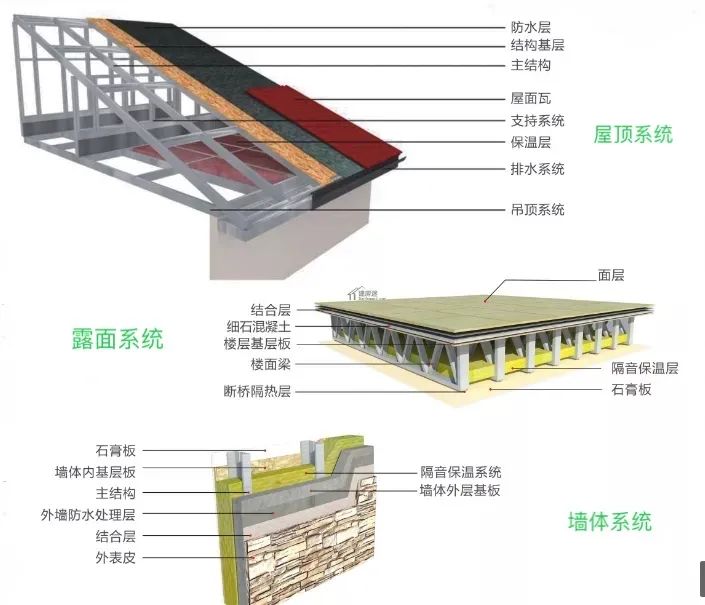

Roof frame ^ 3.

Roof system ^ 2.

Wall framework light steel villa system features 10 times safe construction, mechanized operation and 93% error reduction industrialization.

The materials are recyclable materials, energy saving, environmental protection and pollution-free.

The factory completion rate of our products is between 85% – 95%, which can withstand grade 13 wind force, and the earthquake resistance reaches grade 8.

The double-layer cavity structure of the 3D light steel module is inside the wall.

In this way, while saving heating costs, it reduces the consumption of coal, gas, electricity and other energy, as well as the environmental pollution caused by coal and gas.

Wall system 6.

CCTV’s “into science” authoritative report: ecological house is a building material produced by combining construction waste and crop straw with our independently developed modified polymer, oxidized synthetic powder and high-strength composite fiber.

However, the light steel structure does not use concrete at all, so there is no such problem.

At present, there are more than eight types of precast buildings, which can fully meet the needs of customers in different regions, and is far ahead in the same industry.

Because of the poor thermal insulation performance of traditional houses, the use of coal, electricity, gas and other means of active cooling and heat control of the house temperature is required.

After accurate calculation and the support and combination of accessories, it has a reasonable bearing capacity to replace the special properties of traditional houses.

(9) The seismic performance of light steel villa is good.

(4) Light steel villa has light weight and good seismic performance.

III.

Since the earthquake activity is left-right and up-down, the light steel structure connected with screws forms a safe and stable box, which will not cause wall collapse or floor fall due to earthquake shaking, endangering personal safety.

(10) The construction of light steel villa adopts dry construction method, which will not cause waste of water materials.

Moreover, it takes 40 years for the concrete to be completely dry, so it is easy to cause indoor moisture and humidity, which is not conducive to human health.

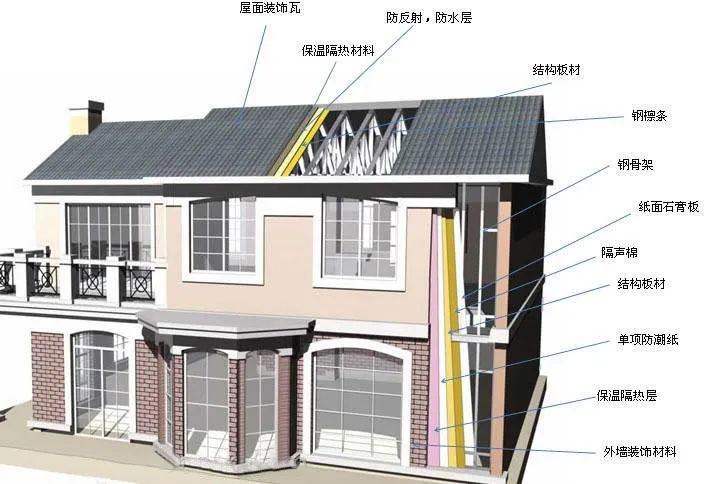

3D light steel module passive house 3D light steel module passive house is called “passive house” because it has “passive” temperature regulation function.

Light steel villa site steel structure 1.

Only the main assembly in the early stage can be completed in two to three days! And the bearing capacity per square meter can reach 2 ~ 3 tons.

With thousands of national patents, it is the general name of high-tech housing construction technology jointly demonstrated by the Ministry of science and technology, Technology Market Association, Ministry of housing and urban rural development, China Construction Standard Design Institute, China Real Estate Association, China Decoration Association and other authoritative departments and expert leaders.

So we invest a lot of manpower and capital to tackle key technologies and reduce costs.

What is technology housing? A single light steel villa can not meet the needs of different regions and different types of customers.

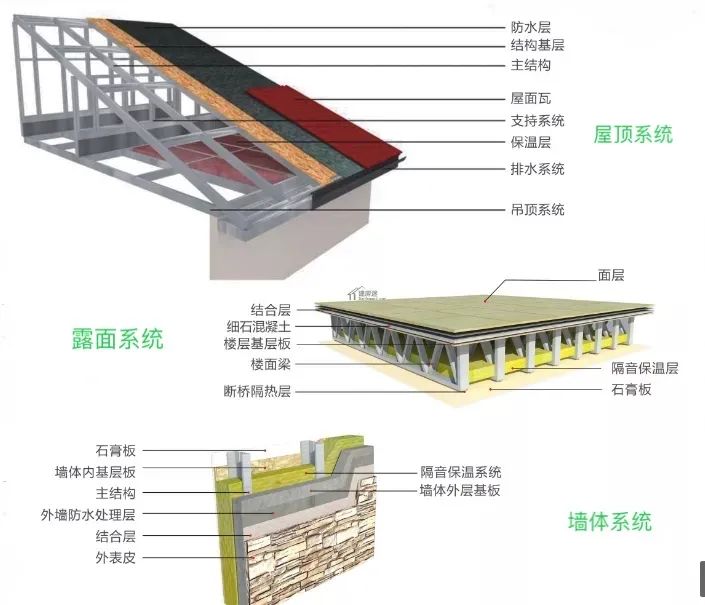

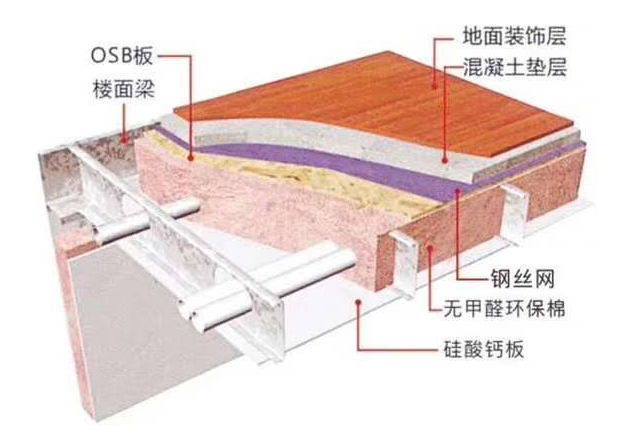

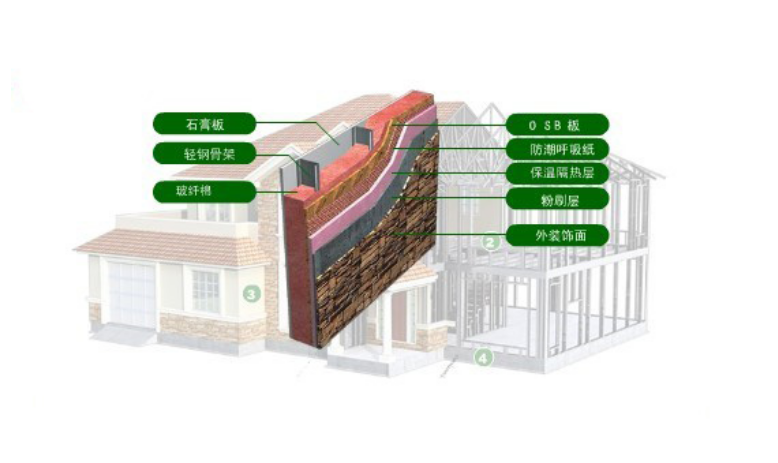

Light steel villa light steel villa, also known as thin-walled light steel structure house, its main material is the light steel keel synthesized by hot-dip galvanized steel strip through cold rolling technology, plus OSB directional structural plate, thermal insulation material, exterior and interior decoration materials.

It is a new material without reinforcement, cement, bricks and tiles, beams, columns, stones and traditional components, fire prevention, waterproof, crack prevention, aging prevention, earthquake prevention, science and technology and environmental protection.

Including super villas, ecological houses, 520 smart villas, etc.

The 3D lightweight steel module passive house adopts a double-layer polystyrene foam profile (EPS) module to form an internal and external thermal insulation layer, and the polystyrene foam profile has excellent thermal insulation and heat insulation performance due to its very low thermal conductivity.

It can be said that it is a revolution in the field of precast architecture! With the support and promotion of the Ministry of housing and urban rural development and other relevant departments, powerful customers can also cooperate in the form of setting up factories to further enlarge your profit space, help quickly seize the market, and promote the landing of precast buildings and the rapid development of beautiful villages! II.

Floor system ^ 4 Floor beam 5.

If the 3D light steel module passive house is used, there is no need for coal-fired heating, which is both economical and safe..

(5) The comprehensive economic index of light steel villa is not higher than that of reinforced concrete structure.

Good heat preservation and insulation performance can achieve the indoor constant temperature of about 15 degrees without heating in winter.

(3) The light steel structure of villa is a sustainable development product.

Ecological house [ecological house] domestic unique core patented technology.

And save money.

Build a two-story villa with an area of 200 square meters.

(7) light steel villa can increase the effective use area compared with brick concrete structure because the wall thickness of light steel structure is small; (8) Compared with the reinforced concrete residence, the light steel structure of the light steel villa can be recycled in the future, but the concrete can not be recycled.

Two layers of thermal insulation layers are built on the external structure to make the heat preservation and heat insulation effect of the house better.

Eight series of science and technology houses 1.

Make full use of natural resources and turn waste into treasure, that is, save energy, save cultivated land and protect the environment.

1.

(6) Compared with brick concrete residence, light steel villa can avoid the waste of resources caused by burning bricks with soil.

The construction period is shorter, which is 1 / 4 less than that of traditional construction methods.

Coal-fired heating not only has a very low heat utilization rate, but also has serious environmental pollution, and the risk of coal stove heating is also relatively large.

(2) The on-site construction speed of light steel villa is fast, which will not affect the nearby residents and is conducive to civilized construction.

In particular, most houses in rural China now use coal-fired heating.

Compared with traditional houses, It has its outstanding advantages: (1) the light steel structure fittings of light steel villas have a high degree of industrialization, mechanization and commercialization.

In the future, it must be construction waste, causing environmental pressure.