Experiment Center – Example Sharing of Fabricated Fair faced Concrete Building Design

The width of wall panel is 700mm, 1400mm and 2100mm, and the height of wall panel is generally 4.3m and 3.56m.

The architectural layout shall meet the requirements of standardization and modularization.

Their application characteristics are shown in Table 1.

Large capacity, inconvenient installation, vacuum extruding cement hollow inner wallboard 1, high flatness; 2.

The project is designed by Hebei Jianyan Architectural Design Co., Ltd.

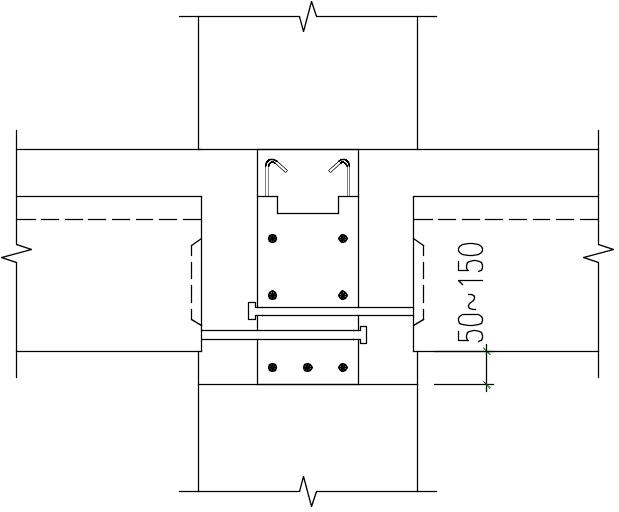

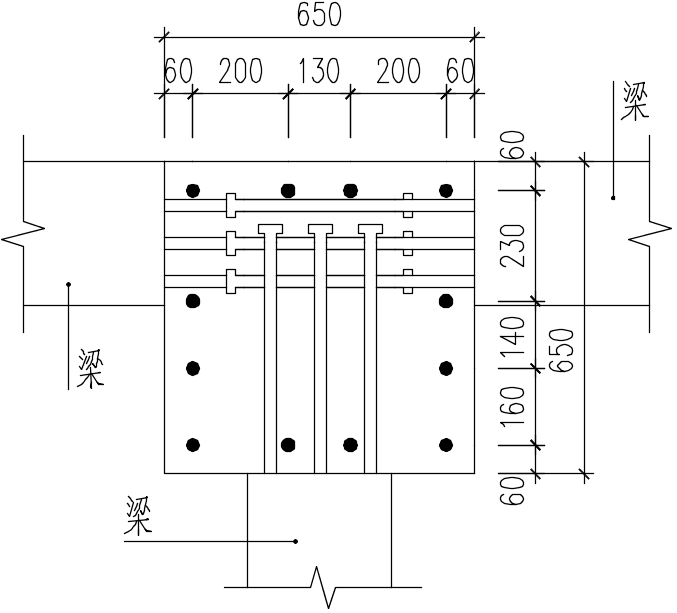

All frame columns from the first floor to the top floor of the structure are precast as cast finish concrete columns, with two types of sections, square columns and columns, and the size is 650mm × 650mm (diameter 650mm).

High cost autoclaved sand aerated light batten 1 has high flatness; 2 Easy to install.

The main building adopts the construction form of precast fair faced concrete, which realizes the combination of fair faced concrete and precast building technology, basically avoids secondary decoration, and better reflects the future development direction of improving the quality and efficiency of precast buildings.

The structure, insulation and decoration are formed in one, reducing the construction process and high construction quality to achieve a hard, flat and even color decoration free texture.

Table 1 Advantages and Disadvantages of Three Kinds of Precast Interior Partition Panels Comparison of Advantages and Disadvantages of Wall Panel Types Precast Clear Water Interior Panel 1 has high flatness; 2 The pipeline is reserved in the factory; 3 Decorative effect of fair faced concrete.

1.

The mechanical and electrical pipelines are arranged reasonably and beautifully, showing the artistic beauty of being close to the building body.

The precast building technologies used include precast columns, precast composite beams, precast composite floors, precast stairs, precast fair faced concrete sandwich external wall panels, precast fair faced internal wall panels, vacuum extruded cement hollow internal wall panels, autoclaved sand aerated light battens, pipeline separation, and full decoration.

The completion picture of the project is shown in Figure 1.

Precast concrete composite beams are used for frame beams and secondary beams from the first floor to the top floor, and the Y-direction precast main beam section is 400mm × 800mm、300mm × 700mm, 300mm section of X direction precast main beam × 750mm、300mm × 600mm, the section of Y-direction precast secondary beam is 300mm × 600mm, 4 sections in total.

Figure 4 Picture of separation pipeline BIM optimization and actual installation effect According to the Evaluation Standard for Fabricated Buildings (GB/T51129-2017), the assembly rate of this project is calculated, as shown in Table 2..

The project has carried out application practice on three types of interior partition panels applicable to precast buildings – precast clean water interior wall panels, vacuum extruded cement hollow interior wall panels, and autoclaved sand aerated light battens.

3 Picture of precast building technical scheme The project has 7 axial spans in the horizontal direction, 7 m in the standard column spacing, and 2 axial spans in the vertical direction.

The interior generally shows the original appearance of precast components.

The total building area of the main building is 5790.89m2, the ground building area is 4937m2, and the building height is 24.1m.

The exterior wall of the building is made of as cast finish concrete sandwich insulation wallboard.

Figure 1 The completion of the experimental center project Picture 2 The concept project of “precast fair faced concrete building” adopts the concept of “precast fair faced concrete building”, and strives to pursue the social development goal of improving the quality and efficiency of buildings, returning to the original nature, and harmonious coexistence between man and nature.

Most ceilings adopt the bare roof scheme.

Strong and weak current and lighting switches of electrical discipline are laid in the public area cable tray in an open way, and are led to the corridor side and laid to the point along the hollow inner wallboard cavity at each room; The lighting pipeline shall be exposed laid in the ceiling after leaving the corridor bridge.

The project consists of a 6-storey main building, a 1-storey podium and a 1-storey underground garage, with a total building area of 9587.58m2.

“Experimental Center” – Example Sharing of Fabricated Fair faced Concrete Building Design 1 Project Overview The experimental center project of Hebei Academy of Building Sciences is located in Luquan District, Shijiazhuang City, Hebei Province, which is an office building for enterprises.

The spans are 8.6m and 6.4m respectively.

The floor slab and roof slab of the laboratory, office and corridor from the first floor to the top floor shall be laminated floor slab, and the toilet and elevator vestibule shall be cast-in-situ floor slab.

The enclosure wall adopts precast fair faced concrete sandwich insulation external wall panel and glass curtain wall.

The slab width is generally 1.9m, 2.1m and 2.55m, and the slab span is generally 3.5m.

The internal precast columns and indoor fair faced decoration complement each other, presenting the most essential aesthetic feeling of the building, as shown in Figure 2.

Separation technology is adopted for equipment pipeline.

The wallboard has the function of building thermal insulation, realizing the integration of structure, thermal insulation, thermal insulation and decoration.

In public space, laboratory, office and other areas, the ceiling is exposed to the original surface of the structure, and some walls are exposed to the original color of fair faced concrete.

3 Picture of indoor partition effect Fig.

Air supply and return pipes, air supply and return pipes, and fresh air supply and exhaust pipes of HVAC discipline shall be laid openly along the bottom of the plate.

The first floor of the building is 4.5m high, and the other floors are 3.75m high.

The above ground part of the project is fully decorated.

2 Picture of outdoor and indoor effects of precast clear water column Fig.

The interior partition wall adopts precast clear water interior wallboard, vacuum extruded cement hollow interior wallboard with clear water surface effect, which is reasonably matched and reconciled with large glass window to express the interior space with modern industrial style, as shown in Figure 3.

Some columns on the first floor are exposed outdoors.

The structural members are flat in appearance and uniform in color, with the characteristics of structural decoration integration.

The main body of the building adopts precast fair faced concrete columns.

The structural form of the project is a precast frame structure sandwich insulation external wall panel concrete composite floor system.

Pipeline holes shall be reserved; 3 Similar to the decoration effect of clear water.

and constructed by Hebei Hechuang Building Energy Saving Technology Co., Ltd.

Fig.

The horizontal water supply pipe and spray pipe of the water supply and drainage discipline are laid open along the bottom of the plate, and the water supply and drainage riser and indoor sewage riser are installed open in the exposed air.

Wet laying of pipeline on site; 2 Puttying and painting are required for secondary decoration.

After optimized layout of exposed equipment pipelines, the indoor ceiling is beautiful, as shown in Figure 4.