How far is it for clean electric floor heating to “carry” precast buildings?

The real estate industry chain is trying to break the ice.

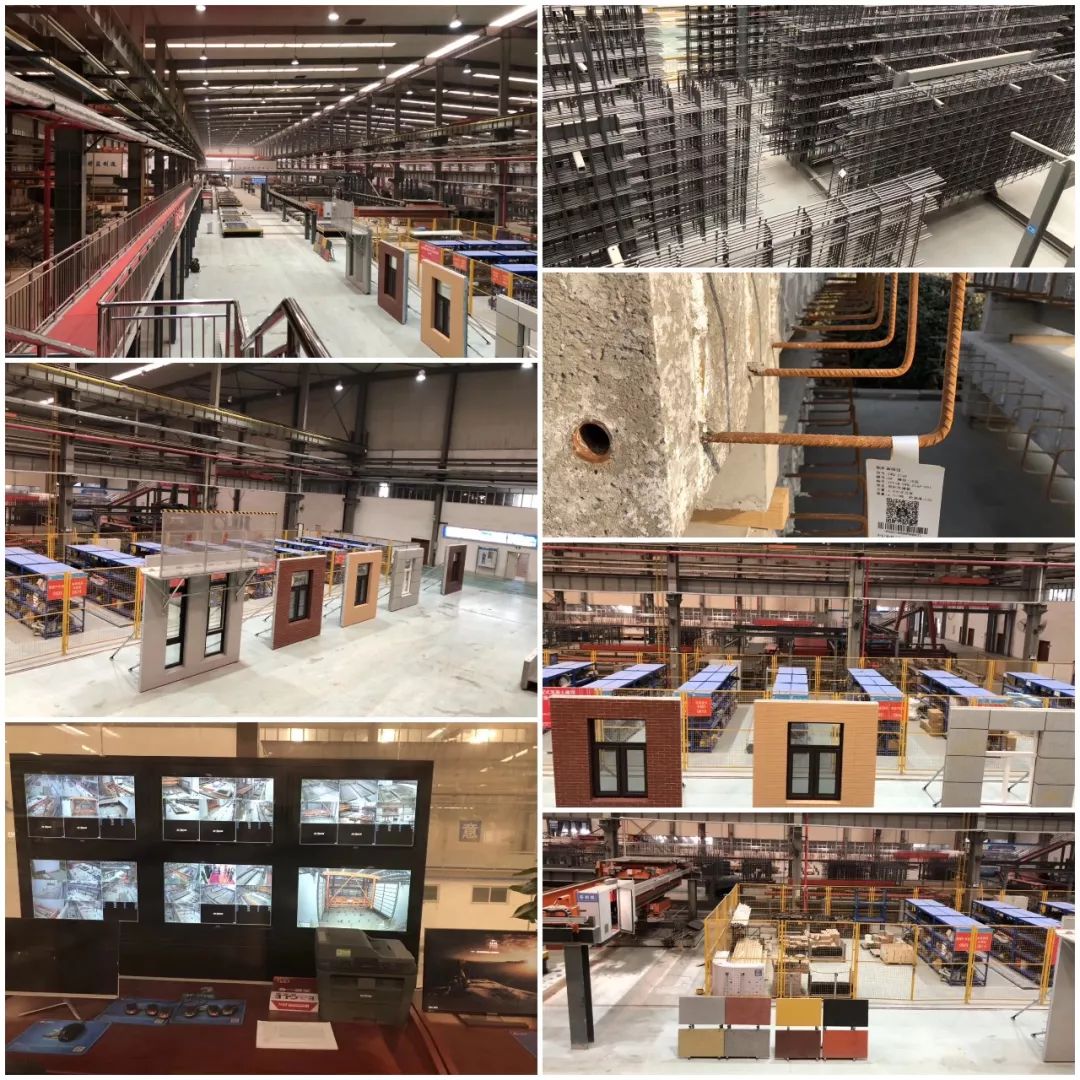

It should be noted that in the design of the heating system, the components of the precast house are usually produced in the factory, so it is necessary to standardize the production of components, which will involve the process design of component components.

It can be applied to multiple types of building electric heating system.

The popularity of BL certified parts has greatly improved the quality of parts and reduced the price of parts.

Winter heating is an important problem in northern China.

From the beginning, Japanese houses were introduced to the market with interior houses.

Si residence evolved from CHS in Japan.

However, China’s precast construction industry is still in its infancy.

With the continuous progress of Japan’s housing system development, the supporting Japanese housing parts industry is also gradually maturing.

In the future trend of housing industrialization, how to take advantage of clean electricity and floor heating? The key lies in design + construction # in the process of continuous development of urbanization, housing industrialization is the trend in the future, and precast housing will also become an important part of residential architecture.

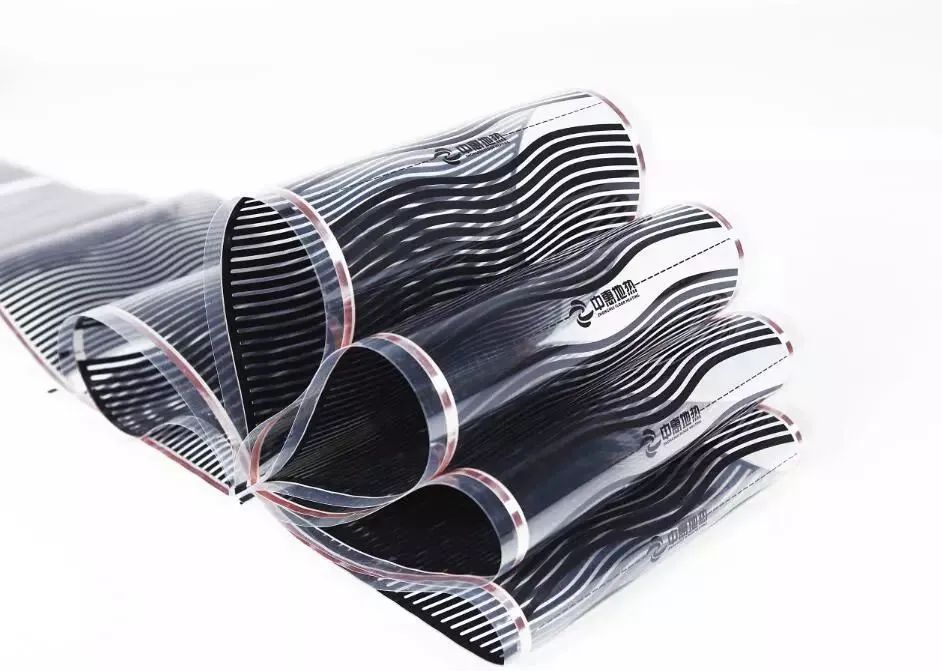

At present, the common dry-type floor heating systems in the market, including electric heating film heating system, realize single household heating in order to achieve the living effect of comfort and energy saving.

This is also an important reason for the large scale, strong development capacity, maturity and standardization of Japan’s housing parts industry.

At the same time, it has played an important role in the standardization, standardization and basic performance of parts.

The electrification of heating methods is undoubtedly the general trend.

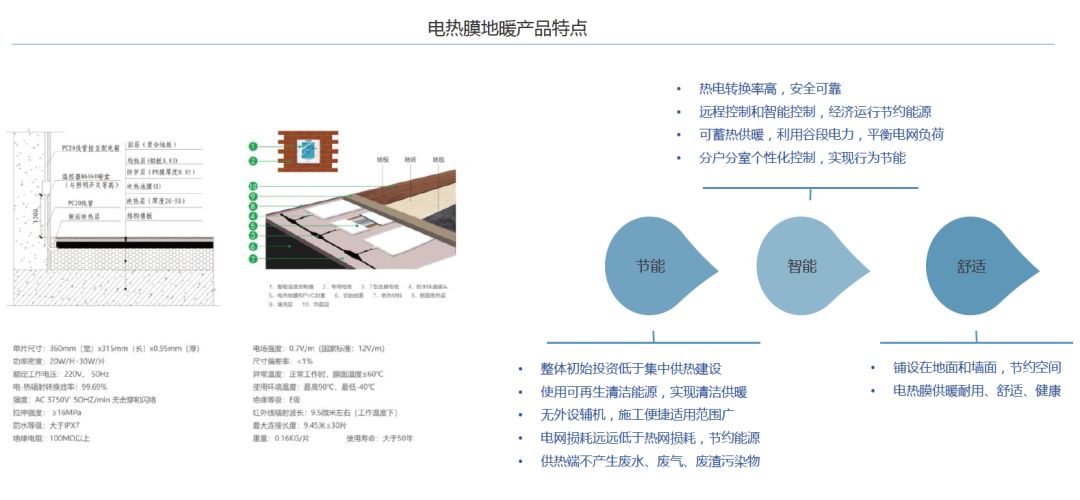

In addition, it is necessary to mark the plane and determine the elevation with fast drawing software, determine the position of the paved ground / wall and the laying materials, so as to fundamentally solve the potential safety hazards and ensure the comfortable experience of the floor heating system.

Intelligent electric heating film heating system not only does not affect the structure of precast buildings, but also flexibly adopts household heating or central heating in the later stage.

The finished height is only 3.14cm.

How can precast buildings break the game? In the future, whose system can become the market leader? How do upstream and downstream enterprises cooperate in the real estate industry chain? With the advantages of flexible control, comfort and energy saving, floor heating system is increasingly used in new buildings.

After construction, the floor height is about 20mm, and only the interface needs to be reserved, which provides great flexibility for the design and construction of precast buildings.

The system does not need indoor pipe network, outdoor pipe network and heat exchange station.

In precast houses, the design and construction of heating system is the key to the design of heating system.

The main body of building structure with high durability; The structural wall and interior parts are completely separated; The indoor pattern has certain variability, which can correspond to the changes of life style in the future; The boundary between the common part and the private part of the house is clear and the responsibility is clear; The main pipeline of the residence is set in the common part to ensure that the pipeline and equipment of the residence can be easily maintained and replaced.

In Europe, America, Japan and other developed countries, heating with electric heating film has a history of at least 50 years, and China has introduced it since 1992.

Japan’s housing performance has been improved to an unprecedented level, and its housing equipment level has been far higher than that of most countries, providing a comfortable and safe living space for Japanese citizens.

The use of internal insulation provides a prerequisite for single household heating.

There are some problems in the industrial chain, such as low degree of information sharing and professional collaboration, which seriously restrict the production efficiency and quality.

According to the change of air temperature, accurately control the indoor temperature without waiting for the arrival of heating period, let alone endure the discomfort of indoor overheating or supercooling, so as to make your heating more humanized and more comfortable.

Drawing on the experience of Japanese part / system standardization, now almost 100% of super high-rise houses in Japan are designed and built with SI system, so as to ensure that the interior decoration can be modified and replaced easily within the service life of 70-100 years, so as to prolong the service life of residential buildings.

The construction materials from bottom to top are 2cm extruded plate, 0.1cm electrothermal film, 0.04cm galvanized plate and 1cm wooden floor.

The heating methods corresponding to various energy sources have their own advantages and disadvantages.

Under the trend of heating electrification, the intelligent electric heating film cleaning heating system is born from the operation.

Generally speaking, the floor slab of precast residence is laminated floor slab, the lower part of which is precast slab and the upper part is cast-in-place slab.

As a residential system, although it has a research history of many years and has different opinions all over the world, it has the following similarities.

In recent years, with the implementation of national policies such as building energy conservation and atmospheric governance, the flexible control of electrothermal membrane heating, the gradual manifestation of energy conservation and environmental protection, and the application proportion in new buildings is increasing day by day..

Its original theory comes from the Netherlands.

The technology of using traditional energy sources, such as coal, natural gas, oil, geothermal and other heating methods is relatively mature, but they are basically faced with problems such as large one-time input resources in the early stage, high operation cost, low thermal efficiency conversion, high intermediate link loss, environmental pollution and so on.

The system is designed according to the building, with fast construction and short construction period, which is 1 / 3 of the traditional plumbing construction cycle.

Precast building is a major and fundamental change in construction mode, an important measure to implement the concept of green development and the development direction of modern construction industry.

Internal insulation helps the heating equipment to rapidly increase the indoor temperature in a short time, which can greatly save energy.