How to design a highly creative precast container building?

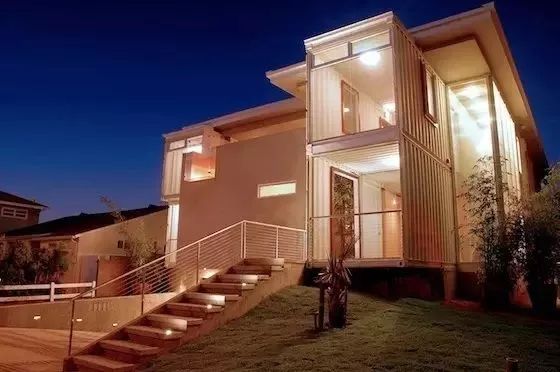

In 2006, Peter DeMaria, an architect in Southern California, designed the first two-story container house in the United States, and the building structure has passed the strict national certification building code.

The container house with good after-sales service is not rusty and green.

The container houses built of this stainless steel material have beautiful surface and diversified use possibilities, more prominent chemical resistance and longer durability than ordinary steel.

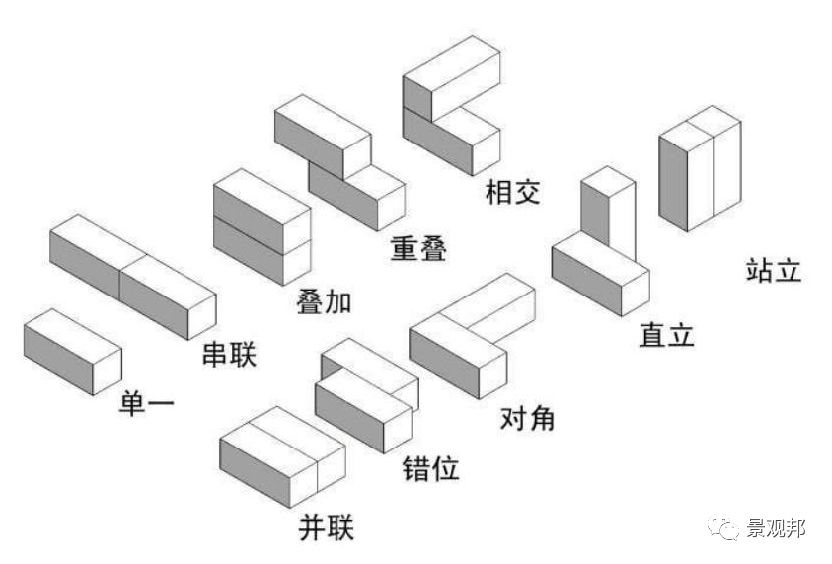

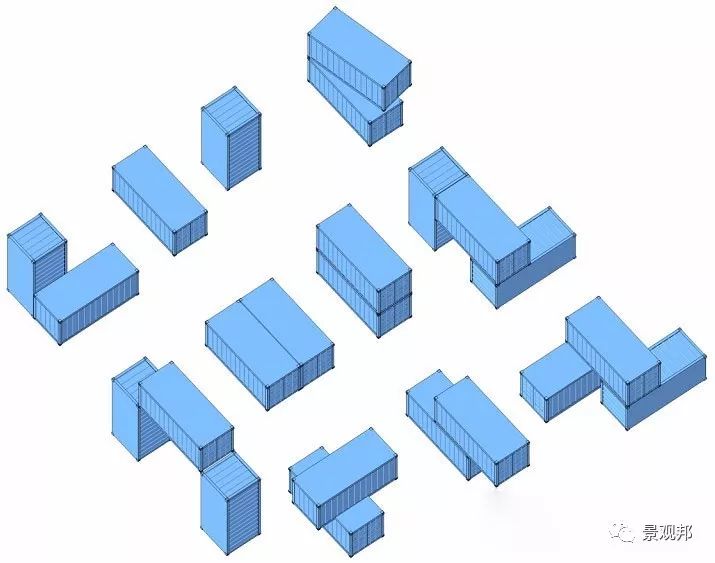

It can be said that the development standard of container building design lies in the combination of container buildings and the expansion of space adaptability.

Boxpark, the world’s first large-scale temporary shopping center, was also launched.

01.

Boxpark, the world’s first large-scale temporary shopping center, container building technology has also begun to mature.

When it becomes waste, it can also be comprehensively utilized.

Container, originally just a simple means of transport, but when people found that it could also be used for living, they got out of control.

If the paint of the container house is found to fall off, it should be repaired as soon as possible to prevent rust from further corroding the materials.

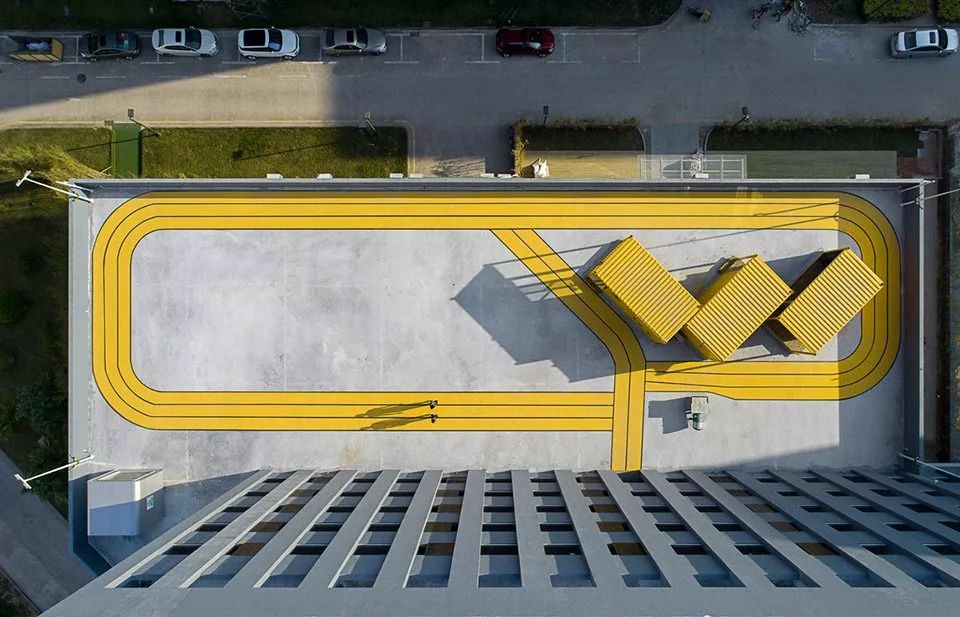

At present, container buildings are mostly used for houses, shops As a new modeling tool and structural tool, various building containers such as art museum gradually show their unique charm and development potential.

This kind of residential container house has high corrosion resistance and good elasticity, which makes it extremely simple in processing.

At the same time, this type of buildings can only belong to temporary buildings, The time limit is short and needs to be demolished or relocated after exceeding the time limit.

Since then, container buildings have gradually appeared.

Therefore, the adaptive combination design of the box is usually done during the transformation.

According to international standards: 20 foot cabinet, bearing 25t, 40 foot cabinet, bearing 45t.

Corrugated board, the main material of container house, plays a decisive role in the service life of container house.

Architects use containers to build houses.

Moreover, the container house supported by wood can also be recycled, which can effectively save costs.

How many years does the container house live? The service life of container mobile house is as little as 2 years and as much as 30 years.

As long as you pass by it, you will be deeply fascinated by it.

The container house made of wood materials has high mechanical strength, strong resistance to mechanical damage and can bear huge loads.

Its development history is only 20 years, but container building has not widely entered our vision in recent 10 years.

In the 1970s, British architect Nicholas Lacey proposed the concept of transforming containers into habitable buildings, but it did not receive widespread attention at that time.

4.

Moreover, this material has the characteristics of good corrosion resistance and high strength.

Therefore, the function of most projects can only be limited to office use or exhibition hall.

The key depends on the material and maintenance.

The residential container houses with high evaluation will use stainless steel for the construction of container houses.

This will extend the service life.

It is easy to build and provide convenient and effective space for people.

The advantages of stainless steel are firm structure, good water tightness and high weldability.

This kind of container houses also have the characteristics of good heat insulation and chemical corrosion resistance.

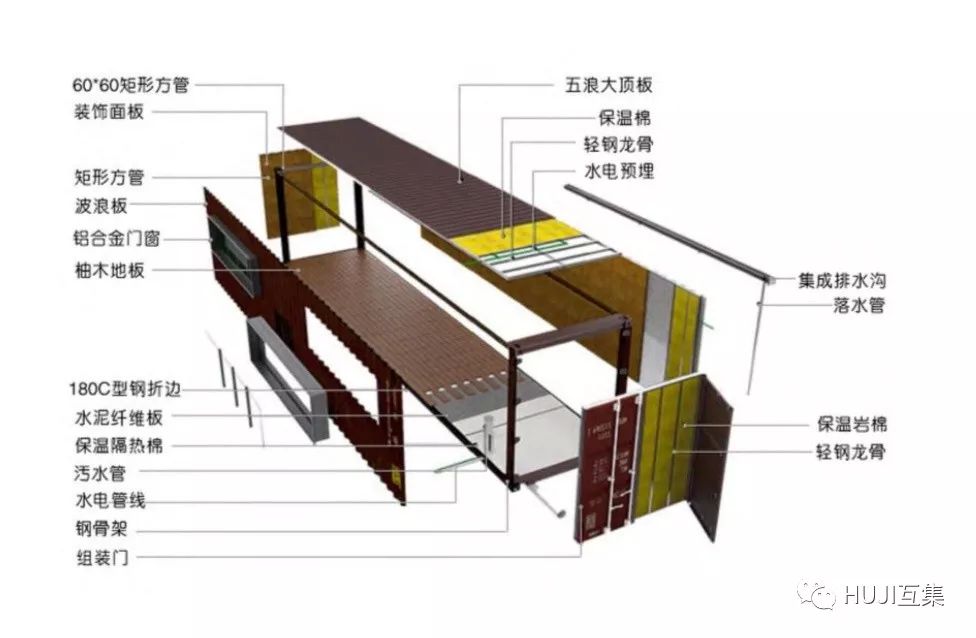

The thickness of the surrounding columns is 1.2mm.

The thickness of the outermost corrugated board, that is, iron sheet, is 0.7mm-1mm.

This low-key new building is not only low-carbon and environmentally friendly, but also exudes a unique artistic atmosphere.

Introduction to containers container building is a brand-new building type.

2.

Because the early container construction technology is simple, it is difficult to pass the national certified building code.

Harsh conditions have not prevented architects from pursuing container construction.

FRP container houses made of FRP materials have the advantages of high strength, high rigidity and large content.

The service life of the container house is also related to the usual maintenance.

What are the common specifications, dimensions and load-bearing of container building? The net space available for the standard size of containers is relatively limited, the indoor height is low, and the horizontal space is narrow and long.

From residential buildings to long-span sports buildings; From small single box buildings to large combined buildings with hundreds of containers, the scale is also very different according to the needs of actual projects.

Until November 1987, American architect Phillip Clark put forward the legal idea of transforming steel shipping containers into buildings The technology patent was passed in August 1989.

The beam at the upper and lower bottom adopts 3mm thick channel steel..

What are the characteristics of containers? What are the container building materials? 1.

Today, we have a deep understanding of the common problems of container building ~02 container building.

Moreover, the director container houses made of FRP are relatively easier to clean and repair.

3.

The first container house in the United States was launched in 2011.

Therefore, the use of this stainless steel sheet can better achieve the purpose of fire resistance.

The scale of container building is increasing, the construction difficulty is also increasing, and the performance of the box in architectural design is also being pushed through the old and brought forth the new.

Through the combination of the box, more kinds of buildings can be created, and the unique artistic quality of the container building can be created.

Aluminum alloy container houses made of aluminum alloy materials have the advantages of light weight, easy construction and beautiful appearance.

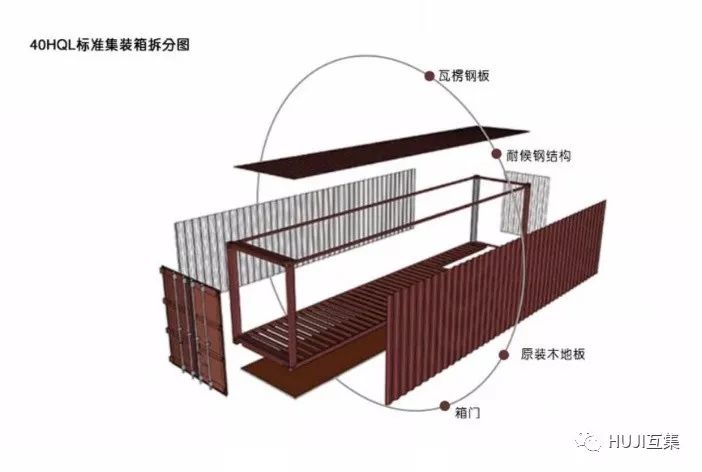

What is the thickness of the container in the container split drawing? The standard thickness of the side plate of the sea box is 1.6mm and the top plate is 2.0mm It can also be customized according to the cost budget and actual needs, such as 2.0mm, 1.4mm, 1.2mm, 1.0mm, 0.8mm, etc.

The processing fee and repair fee of the container house built of aluminum alloy are also relatively low.