Industry thinking – excerpt 2 of the 2021 national precast building development report

In order to popularize building industrialization and precast technology under the historical conditions at that time, the concept of “equivalent cast-in-situ” or “cast-in-situ equivalent” is proposed, that is, the precast building is designed according to the cast-in-situ structural system.

Jgj2014 technical specification for cast reinforced concrete structures, which is planned to replace this version of the standard, is still in the process of preparing the first draft.

As a result, the reality is that designers blindly “split” the cast-in-situ structural system, resulting in many problems such as “assembly for assembly”, simple and rough “splitting”, wrong design of connecting nodes, difficult connection, poor quality of component production and installation, and many hidden dangers of quality and safety.

2021 is the first year of the national “14th five year plan” strategic plan, and the development plans of precast buildings and green buildings are being deployed all over the country.

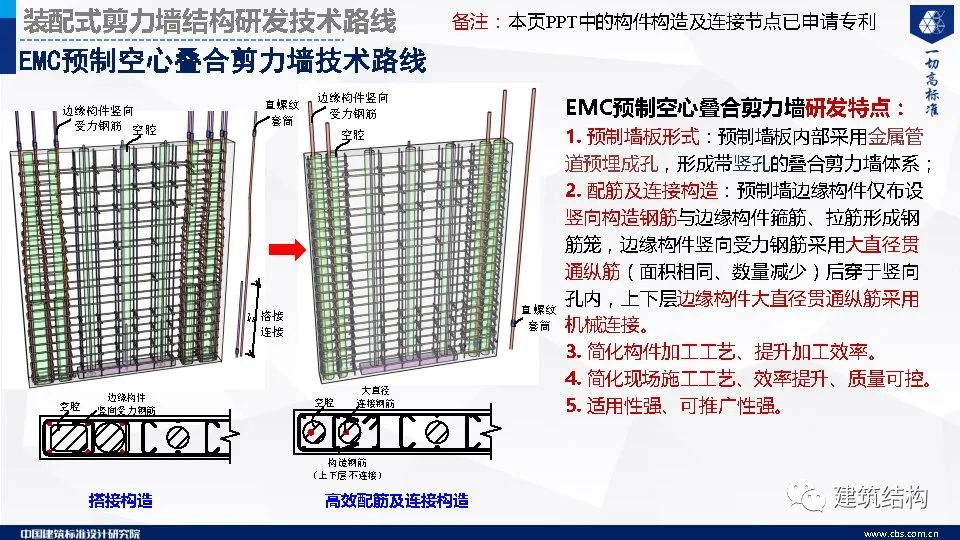

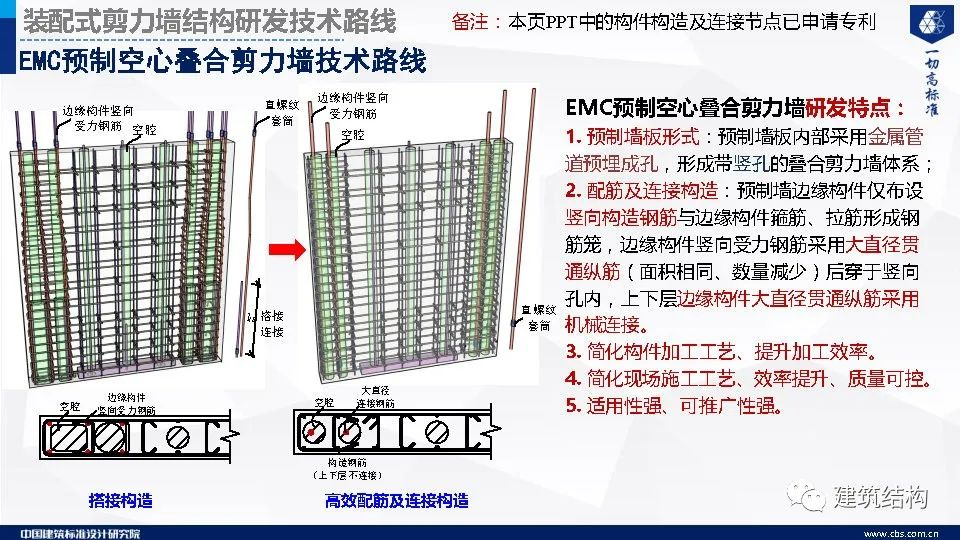

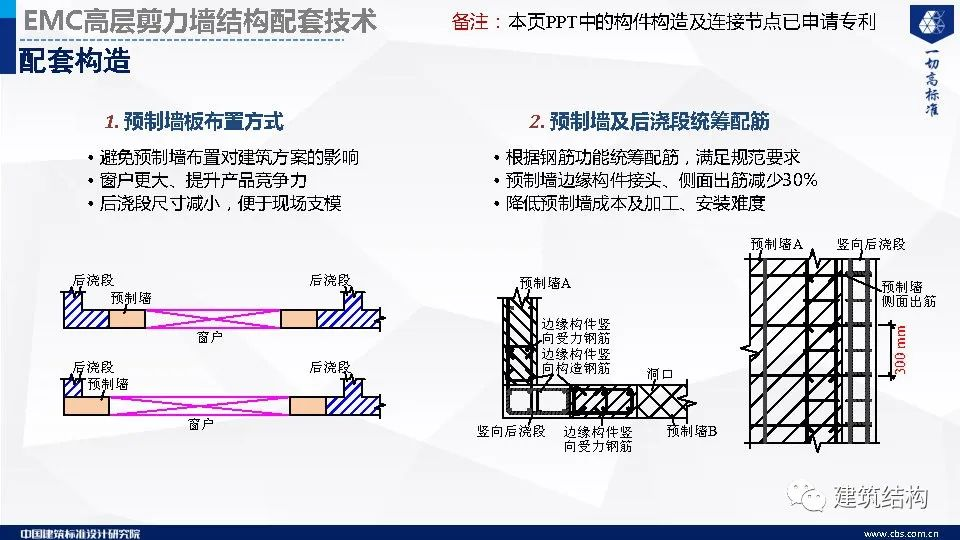

The following figure shows Master Yu’s EMC technology system.

2021 is a thinking year for the cast construction industry.

Promoting the industrialization of new buildings represented by precast buildings and intelligent construction is an inevitable choice to promote the formation of a green, low-carbon, energy-saving and environmental friendly production mode and drive the comprehensive transformation and upgrading of the domestic construction industry.

New sleeve free grouting technology system has sprung up.

At present, almost all concrete building standards in China are “cast-in-situ concrete” technology, and all design software (drawing review company and officially recognized) are prepared for “cast-in-situ concrete” technology.

Almost all industry personnel study, study and apply the “cast-in-situ concrete” technology.

So that the follow-up design, R & D and practice can be standardized and finally implemented.

In this issue, we will share “from equivalent cast-in-situ to non equivalent cast-in-situ”.

From “equivalent cast-in-situ structure” to “non equivalent cast-in-situ structure” — EMC precast concrete structure system technology research and development (Master Yu Yinquan of Standards Institute) Master Yu Yinquan of China architectural standards design and Research Institute proposed EMC precast concrete structure system with non equivalent cast-in-situ structure, gradually cleared away the obstacles to the development of precast buildings and explored a new way for the healthy development of precast buildings.

In view of the relevant information on the development of China’s precast building industry in 2021, we collected, sorted and interpreted it to form the national precast building development report in 2021.

This was a “helpless act” of “expediency” at that time.

In order to improve the enthusiasm of building precast buildings and green buildings, national ministries, commissions and provinces and cities have intensively issued a series of incentive policies, including financial subsidies, priority awards, credit and financial support, reduction and exemption of urban supporting costs, etc.

The following is the context of equivalent cast-in-situ to non equivalent cast-in-situ.

After eight years of hard work, jgj1-2014 technical specification for precast concrete structures was finally compiled.

More than a dozen experts, including experts in charge of the urban and rural construction industry, were strongly invited to participate in the review meeting of the national survey and housing structure promotion committee in accordance with the provisions of the Ministry of housing and urban rural development at that time, Finally, the technical route of “equivalent cast-in-situ” proposed by Beijing Architectural Design and Research Institute is determined.

Industry executives and experts have entered a deep level of thinking, how to solve the bottleneck hindering the development of precast buildings? It is agreed that from equivalent cast-in-situ to non equivalent cast-in-situ is the inevitable trend of the development of precast buildings in China.

Figure | Master Yu Yinquan’s EMC technology system | source of this article: China Construction Association certification, which is only used for Industry Exchange and reference…

At the beginning of our research, we faced the dilemma of “no standards, no norms”.

It is believed that the road of precast buildings will be wider and wider and the prospect will be better.

In other words, in the absence of design theories and methods for the characteristics of cast structure system, the technical route of “equivalent cast-in-situ” is preliminarily determined.

The situation of “lack of standards and specifications” makes it difficult for the project team.

From equivalent cast-in-situ to non equivalent cast-in-situ, in 2021, the cast construction industry has developed rapidly for nearly 10 years, including achievements and many problems.

Under the important historical background of “the demographic dividend will subside in the future, the labor price will rise, and the state should vigorously develop precast buildings”, the design concept of “equivalent cast-in-situ” can be said to be the result of compromise by all parties at present.

“New development of precast buildings in Beijing since 2007” — fan Zesen, chief architect of CSCEC science and technology, the precast buildings can be described as “a hundred wastes waiting for prosperity” after spanning the “stagnation period” of more than ten years at the turn of the century.

We look down and look up at the road.

When the state revised the code for design and construction of precast large slab residential buildings (jgj1-91) in 2006, the basic research data and most technical product data used, such as the grouting sleeve used in precast frames in Japan and the United States, the “double skin wall” in Germany, the truss reinforced composite floor slab in Europe, the flat formwork flow automatic production line in Europe, the “sandwich” concrete insulation wallboard in Europe and America, etc, They are all foreign.

Since jgj1 (1990 edition) has not been revised for 15 years, it is completely inapplicable.

The working principle of “equivalent cast-in-situ” is to effectively connect the pre cast components (mainly most of the external walls) with the cast-in-situ part through the reliable connection between the reinforcement (such as “slurry anchor grouting”, “reinforcement lap”, “grouting sleeve” connection, etc.), so as to make the whole cast structure “equivalent” to the cast-in-situ and meet the safety requirements of the building structure.