Interpretation of structural design of cast supports and hangers

Permanent load – such as the gravity action of the pipeline itself; 2.

Design service life and limit state: when the members of cast supports and hangers (such as channel steel, square steel, etc.), member connectors (such as right angle connectors, seismic connectors, etc.), pipe components (such as pipe clamps), anchors connected with the main body of the structure (such as anchor bolts, embedded slots, etc.) and steel structure connectors (such as beam clamps, hoops, etc.) bear the above loads, It may fail in the limit state.

Based on the principle of reliability code gb50068-2018, the limit state design method based on probability theory shall be adopted for the support and hanger structure, the reliability of structural members shall be measured by reliability index, and the design expression of partial coefficient shall be adopted for the design.

The specific partial load factor shall be based on the unified standard for reliability design of building structures, and integrate the load specifications of various buildings and structures and the design specifications of electromechanical HVAC specialty.

Taking general civil buildings as an example, the design service life of cast supports and hangers can consider the design service life of equipment pipelines.

Vibration on both sides of the pipeline and differential settlement of the support due to thermal expansion and contraction of the pipeline; 4.

Practice is the only standard to test the truth.

It also has the effects of displacement control, vibration isolation and shock absorption.

In structural design, the types of limit state failure are as follows: 1) ultimate failure of bearing capacity: for example, strength failure and brittle fracture of components or connections, loss of stability of structures or components, change from geometric invariant system to mobile system, or excessive deformation unsuitable for continuous bearing, etc; 2) Failure of serviceability limit state: for example, deformation and Vibration Affecting the normal use or appearance of structural members and non structural members, local damage affecting normal use or durability, etc.

Earthquake action, etc.

Fabricated supports and hangers can be considered as “light steel structure without welding”: it not only has many characteristics of high strength, light weight, high reliability and good seismic performance of steel structure, but also has the advantages of high precision, replaceable, flexible and controllable of cast buildings without welding.

This idea is also consistent with the reliability standard of our country..

Considering that cast supports and hangers are non structural members, the design service life of cast supports and hangers in general civil buildings is mostly 25 years or less.

The type of support and hanger is relatively complex.

However, the connection forms of support and hanger members and members, pipe parts and pipelines, and pipe parts and members are different from those of traditional steel structure members.

Therefore, there is no basis in the above two steel structure specifications.

From the perspective of safety and convenient design, it is reasonable to adopt the first-order or second-order elastic analysis method.

One of the main functions of cast supports and hangers is to transfer the load borne by electromechanical equipment and auxiliary pipelines to building structural members.

After the preliminary type selection and layout of supports and hangers are completed, a very important link in the design of supports and hangers is the structural design of supports and hangers: according to the type and size of loads borne by supports and hangers, the structural checking calculation and design of supports and hangers can be carried out accordingly, so as to ensure the bearing capacity and normal use of the structural system of supports and hangers.

When seismic design is required, gb50981 code for seismic design of building electromechanical engineering shall also be considered; The specific safety factors of materials, components and connections shall be based on the current GB50017 code for design of steel structures and GB / t50018 technical specification for cold formed thin-walled steel sections, as well as the product specifications, integrate the manufacturer’s product characteristics, and measure the reliability of cast support and hanger parts and components on the basis of probability theory.

At this stage, in different projects, the time period when the supports and hangers do not fail in the limit state may also be different due to the types of projects and their own design requirements.

The finite element analysis of the support and hanger structure can be carried out by using the bar model in order to obtain the more accurate stress of each element; At the same time, due to the complex force expression form of the connector, the force transmission property is not necessarily complete rigid connection or hinge.

In the structural analysis of the support and hanger, the rod connection node can be considered as hinge to ensure safety.

At the same time, the design service life of “easily replaceable structural members” specified in gb50068 is 25 years.

According to the current code gb50068 unified standard for reliability design of building structures, the purpose of structural design in China is to “meet the requirements of advanced technology, economic rationality, safety and applicability and ensure quality”, and there will be no limit state failure in the specified design service life.

Design of members and connectors ― for members of support and hanger structure: for example, the suspender of single pipe support and hanger, the beam and column of portal support and hanger, or the diagonal brace of seismic support and hanger, the current member design method of bending, compression, tension and composite stress such as tension bending and compression bending in China shall be referred to according to the steel material and section characteristics of members, Conduct strength and stability design.

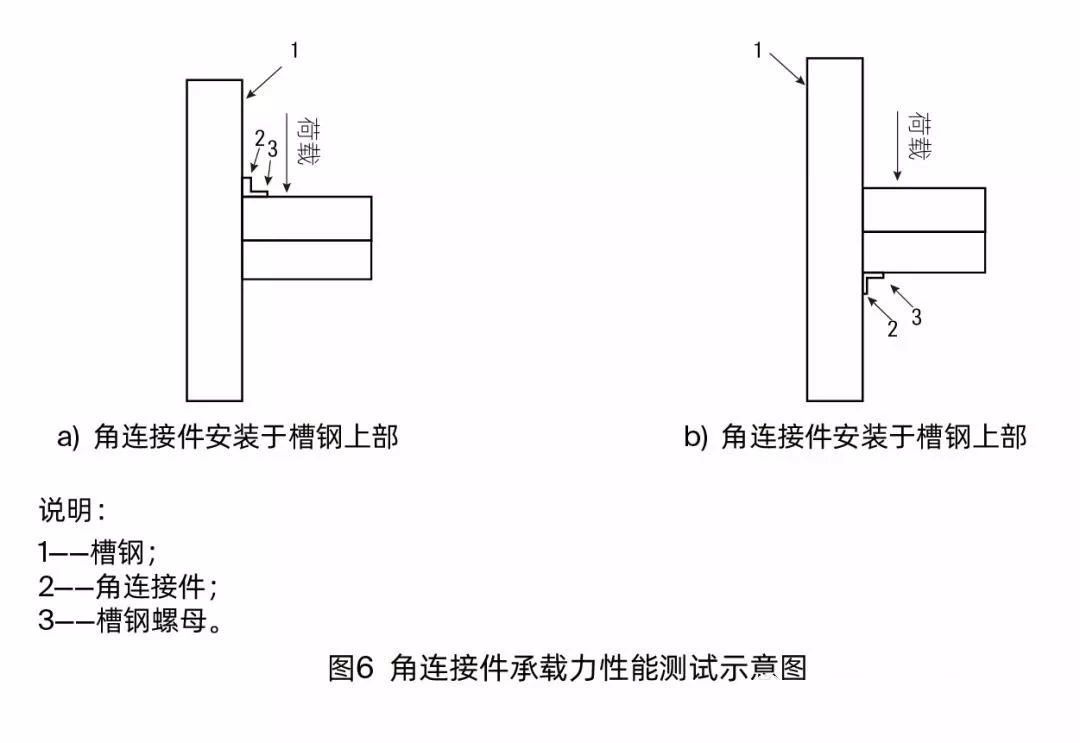

The bearing capacity and stiffness of the connecting joints of supports and hangers are confirmed by the test and data processing method based on the probability distribution theory.

Load action: according to the relevant design specifications of various disciplines, the actual situation and technical parameters of equipment and pipelines, the loads that the cast support and hanger system may bear include but are not limited to the following types: 1.

Structural analysis} from the common cast support and hanger components on the market, most of the components are cold-formed thin-walled steel components.

Variable load – for example, the construction load of indoor supports and hangers, and the snow, rain and wind load that may be borne by outdoor supports and hangers; 3.

This is also in line with the current analysis methods of GB50017 code for design of steel structures and GB / t50018 technical code for cold formed thin wall steel.