Introduction to “advanced, mature and applicable new technology” of precast buildings – composite stressed sandwich composite external wall

The composite exterior wall panel has good durability and has the same service life as the main structure.

3 inorganic material sealing system 2 Technical index as a component of precast building, the composite external wall hanging plate shall comply with the relevant provisions of the current national standards technical standard for precast concrete buildings GB / t51231, technical standard for precast steel structure buildings GB / t51232 and technical code for precast concrete structures jgj1.

The composite external wall hanging board shall be designed for fire protection.

Under the 9-degree earthquake, the overall wall panel remains intact.

1 composite stressed sandwich composite external wall hanging plate the composite external wall hanging plate and the main structure are connected by a “lower support and upper pull” flexible connection node.

During construction, the coating is mixed according to the specifications.

6.

5.

Fig.

The scope of application is applicable to schools, residences, apartments, office buildings, etc.

Recommended unit: Shandong University 1 Technical content combined stress sandwich composite exterior wall hanging plate (hereinafter referred to as composite exterior wall hanging plate) refers to a non load-bearing exterior wall plate composed of reinforced concrete inner leaf plate, thermal insulation core plate, reinforced concrete outer leaf plate and shear connectors, which effectively connect the inner and outer leaf plates into one through shear connectors, cooperate with deformation and common stress, and install them on steel structure or concrete frame structure buildings in a dry hanging manner.

of multi-storey, high-rise and super high-rise buildings.

The connection between the outer wall panel and the main structure is simple, and the installation speed is fast.

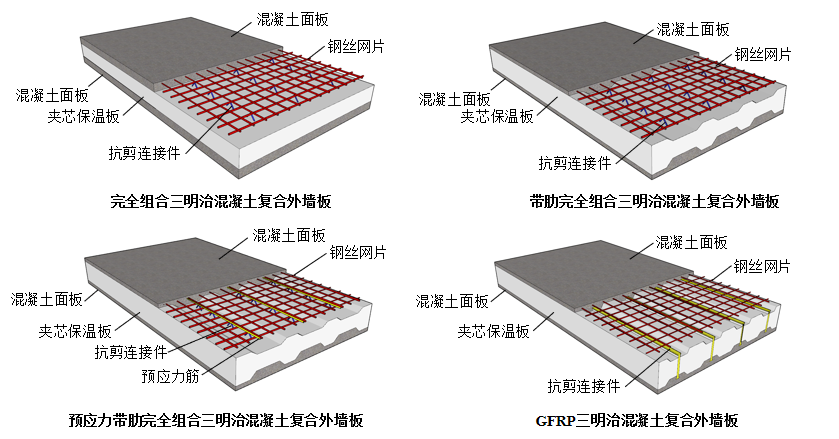

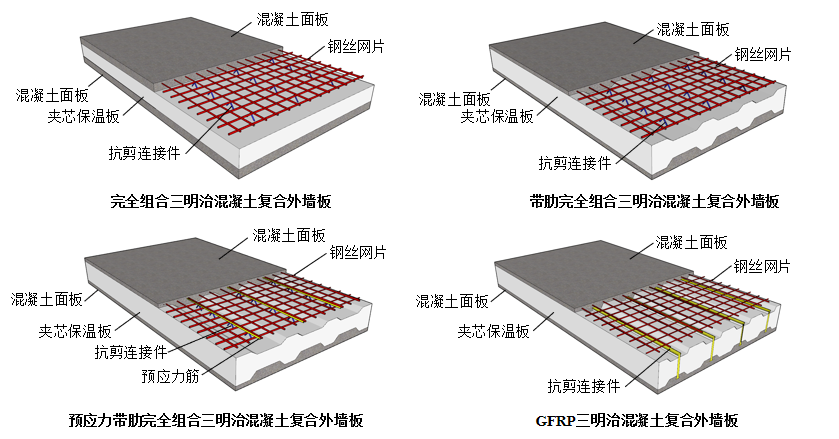

Composite exterior wall hanging board mainly includes the following four types: fully combined sandwich flat concrete composite exterior wall board; Fully combined sandwich concrete composite exterior wall slab with ribs; Prestressed ribbed fully combined sandwich concrete composite exterior wall slab; GFRP is a ribbed fully combined sandwich concrete composite exterior wall slab as a shear connector.

The exterior wall panel and the main structure are connected flexibly, with superior seismic performance.

As a building exterior wall panel, the thermal design of composite exterior wall hanging plate should also meet the provisions of the current national standard code for thermal design of civil buildings (gb50176).

The joint should adopt tongue and groove structure, and the joint position should correspond to the building facade division; The width of slab joint shall be designed and calculated according to the factors such as vertical grid division, ultimate temperature deformation, interlayer displacement under wind load and earthquake, maximum tensile compression deformation of sealing material, construction and installation error, and the joint width shall be in the range of 15 ~ 25mm.

4.

5.

Fig.

4.

The upper pull node is a Z-shaped spring and the lower support node is an L-shaped steel support.

After the qualified substrate surface is simply cleaned and filled, the rough surface of the inorganic sealing belt is soaked and pasted on the pretreated base surface, flattened and compacted.

5.

3.

3.

The embedded parts connecting nodes, embedded parts for hoisting and embedded parts for temporary support should be set separately and should not be used at the same time.

At the same time, it can ensure the normal water vapor diffusion of wall and other substrates and avoid mold damage.

Project examples: Anhui Bengbu dayujiayuan public rental housing project, Shandong Jiyang second experimental primary school, Shandong Mingda construction technology demonstration model room, Shandong Qingdao Yanghe town police station office building…

This node can protect the external wall plate from damage before the main structure in case of earthquake.

When the combustion performance grade of sandwich insulation material is B1 or B2, the thickness of inner and outer concrete layers shall not be less than 50mm; The adjustment gap between the exposed metal support and the inner side of the composite wallboard and the main structure shall also be blocked according to the requirements.

The inorganic sealing belt is made of water-based materials, which is environmentally friendly, non-toxic and non corrosive; The bonding strength of inorganic sealing tape reaches 0.6 ~ 1.8MPa; The inorganic sealing belt has good aging resistance (the same service life as the building, passing the ultraviolet 1000h artificial aging test); The sealing performance of inorganic sealing belt remains unchanged over the years, which can achieve the same service life as the building, with excellent waterproof performance and good air tightness.

Joints should avoid crossing the fire compartment; When the joint crosses the fire compartment, the indoor side of the joint shall be sealed with refractory materials.

2.

3.

2.

2 the seam of the composite external wall hanging plate of the lower support and pull-up connection node is sealed by the inorganic material sealing system, which integrates the advantages of coating, film, coiled material and other materials.

Fig.

4.

The joint shall be provided with structural measures to prevent the formation of thermal bridge.

The design and construction shall also meet the current national standards code for design of concrete structures GB50010, code for construction of concrete structures gb50666 Code for acceptance of construction quality of concrete structures (GB50204).

The composite external wall hanging plate shall also meet the following requirements in design and installation: 1 The design shall meet the requirements of building modulus coordination and standardization, meet the conditions of building facade effect, manufacturing process, transportation and construction and installation, and realize serialization and diversification on the basis of standardized design in accordance with the principle of less specifications and more combinations.

Technical advantages 1 The energy-saving and thermal insulation effect of composite exterior wall panel can reach 85%, and the weight is as low as 130kg / m2.

Install a panel in 5 minutes.

The composite exterior wall panel is fully combined, with strong cracking resistance, and the cracking load reaches 410kg / m2.

The number and location of connection points shall meet the load-bearing requirements, and the nodes shall have the three-dimensional adjustment ability to eliminate construction errors and the ability to adapt to temperature deformation.