Lao Zhang rural 887 every flat built precast foreign house, the wall is so strong that the sledgehammer can’t hit it!

From the foundation to the external decoration, Lao Zhang only spent 320000 yuan to build a small two-story foreign house with a construction area of 361 square meters, which is really very cost-effective.

Do you think the full frame shear wall of Zhuo Rui’s house is strong enough? How is such a wall constructed? I believe you must be full of curiosity.

In the past two or three years, he can only receive two or three jobs a year.

This is the house just built by Lao Zhang’s family.

Before, the residential park also shared with you Zhuo Rui’s precast building with full frame shear wall.

The wall is fully cast-in-situ, and the formwork of door and window holes can be erected with steel plate.

Ceramic tile, cultural stone, dry hanging stone, painting, and various external decoration materials can be used at will.

When building a house with EPS foam, after plastering the interior wall, steel wire mesh should also be hung at the place where the kitchen and bathroom walls need to be tiled, otherwise the pulling force is not enough.

In fact, the full frame shear wall system of zhuorei building is completely different from EPS foam module system.

The formwork free decorative integrated wallboard built by Zhuo Rui can not only be processed and formed in the factory according to the designed architectural drawings, but also be decorated after the main body is built like a traditional red brick house.

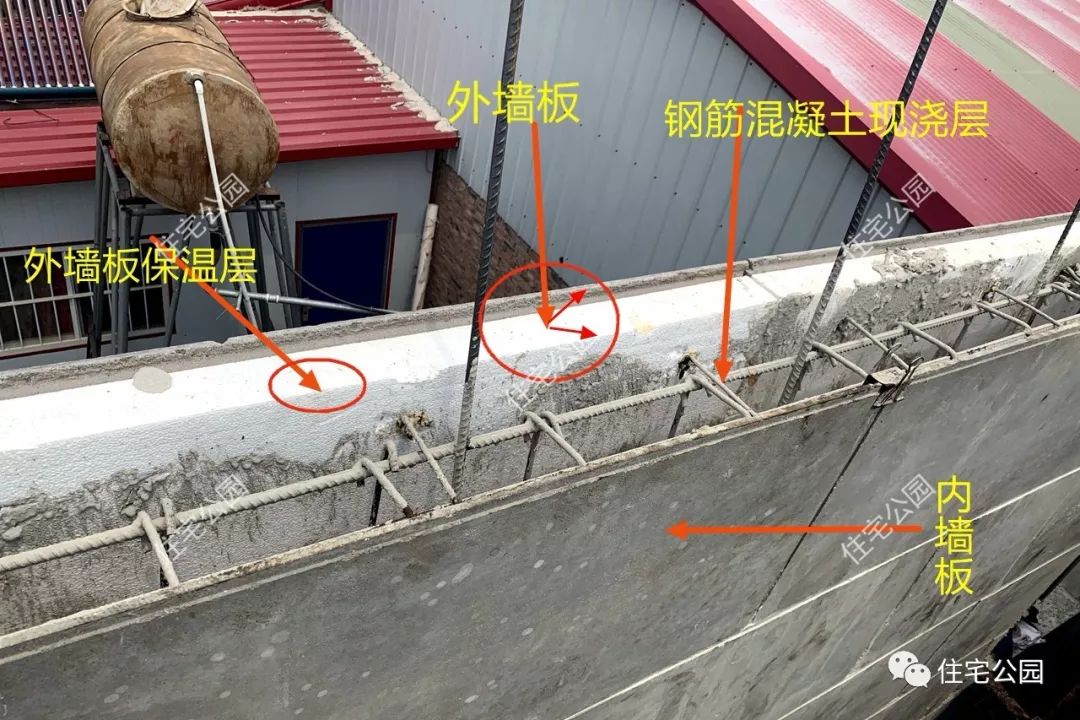

The internal and external wall panels of the integrated assembly type residence of formwork free thermal insulation and decoration built by Zhuo Rui are precast formwork free thermal insulation and decoration integrated panels made of concrete.

When he has time, Lao Zhang finds it more difficult to build a suite for himself.

However, the whole frame shear wall wall of Zhuo Rui’s house does not move, and the dust is not brought up.

The villagers also talked about this new building.

In order to dispel the villagers’ doubts, Lao Zhang decided to do a test after discussing with the construction personnel.

The external wall panel is provided with thermal insulation layer and external wall decoration.

Because the surface layer is foam, the wall cannot be installed with background wall at will according to the decoration needs.

He was busy until the end of the year and didn’t have time to build a new home for himself.

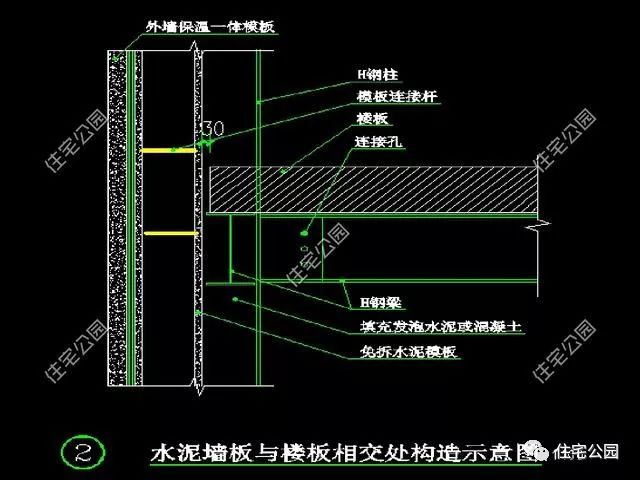

The connector not only makes the inner and outer wall panels firmly connected together, but also adjusts the thickness of the cast-in-situ layer of the middle cavity concrete by adjusting the length of the connector.

The internal and external wall panels are connected through connectors of patented technology, and the commercial concrete is cast in place in the middle cavity.

Whether the wall is strong enough or not is up to you the final say after reading it! Lao Zhang in Bazhou, Hebei Province, is a rural contractor.

Let’s answer your questions about this new rural house in detail through comparison.

Therefore, the wall with different thickness can be adopted according to the needs of the owner.

When the owner designs the drawings, it will not be limited because of the precast house built by Zhuo Rui.

Take your home as a model house, bring this affordable and high-performance precast house into your hometown, and give villagers a house that can save money and use better.

The precast house built by Zhuo Rui, Roman column, beam bracket and balcony guardrail are poured with special formwork, which is beautiful, solid and durable.

Because the red brick was banned, all small brick factories were closed, the supply of red brick in large brick factories was in short supply, the price rose sharply, and it was also shut down in winter.

The precast wallboard can be cut at will according to the design drawings, and various appearance shapes and roof shapes can be made.

At first glance, the template free thermal insulation and decoration integrated assembled residential system built by zhuorei is very similar to EPS foam building, but in fact it is completely different.

The inner and outer wall panels are precast in the factory and transported directly to the site.

After the soft soil on the surface is excavated, a layer of plain concrete cushion shall be poured first, then the reinforcement shall be bound, and the raft foundation layer shall be poured..

It’s really difficult to build another red brick house.

Lao Zhang also thought: “since it is inevitable that the traditional red brick houses fade out of the home building market, why don’t you take advantage of the opportunity of building your own house and walk forward with the rise of new material precast houses in rural areas?” After repeated comparison, Lao Zhang was deeply attracted by the template free thermal insulation decoration integrated assembled house built by Zhuo Rui, and decided to choose it.

After the curing is in place, remove the formwork and prepare for the exterior wall decoration construction.

The frame shear wall precast house built by Zhuo Rui has no special requirements for the foundation.

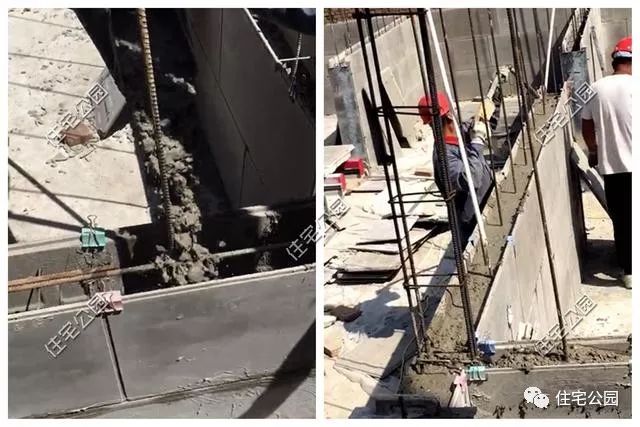

After the wallboard is assembled, commercial concrete is used for cast-in-situ in the middle.

It needs to be decorated indoors according to the precast fixed reserved parts designed during the building.

The wallboard is very strong and can be cut according to the needs of on-site construction, water and electricity wiring, indoor and outdoor decoration, etc.

However, many friends confuse it with EPS foam module housing, thinking that this is also a form of EPS foam module housing.

“Is the wall strong enough?” “How many years can it last?” “Will it fall down when the wind blows?” When it comes to rural precast houses, we always have such questions.

Build a foreign style villa in the countryside, the appearance must be beautiful.

Bind the wall reinforcement and assemble the inner and outer wall panels.

After repeated communication with Zhuo Rui’s building designer and engineer, he decided to adopt raft foundation.

The following figure of wall system shows the familiar EPS foam module for building.

Let’s have a comprehensive understanding of it.

Like the traditional red brick house, it adapts measures to local conditions during construction.

Install the guardrail formwork of balcony gourd bottle.

Lao Zhang’s house is surrounded by neighbors.

Today we will answer these questions with the most direct test.

If the sledgehammer is swung down hard, even the red brick wall may break a hole, let alone the EPS system with foam modules inside and outside the wall.

Is the wall such as Zhuo Rui’s building strong enough? Let’s take a look at the field measurement.

After asking around, Lao Zhang found that many villagers began to try to build precast houses with new materials, and many of the same industry began to turn to precast houses.

If the owner has limited terrain and traffic, self mixing concrete can be used for cast-in-situ.

There must be many shapes such as Roman column, gourd bottle and beam bracket.

EPS foam module is used to replace the formwork, foam is used to connect the foam module of internal and external walls, and foam concrete is used to fill and pour in the cavity.

In previous years, he had to build seven or eight houses every year.