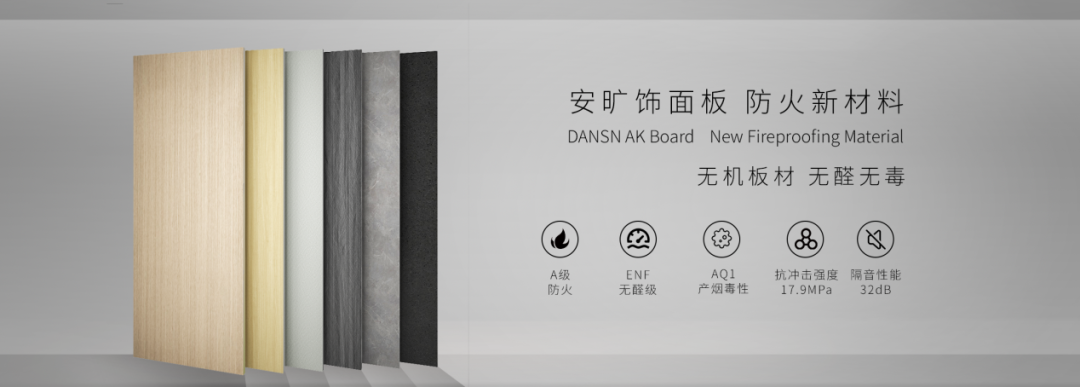

Member style | ambian innovates and develops cast wall panels, subverting traditional inorganic new materials

An Kuang metal composite board, which is not class A1, can effectively improve the fire resistance limit of walls and ceilings, and can last for more than 4 hours.

It is applicable to the integration of decorative partition walls with fire prevention or sound insulation requirements.

Inorganic materials have strong flame retardance, fire resistance integrity can reach 4 hours, and fire and heat insulation can reach 1 hour.

After natural curing, a honeycomb closed foam pore structure is formed inside the structure, which has the texture effect of “both ore and board”.

It effectively fills the gap in the industry market, and also provides building materials with independent patents for the installation and distribution system of Abe.

Ankuang decorative panel has a variety of densities, high strength, strong nail holding force, and a single point hanging force of 50kg.

As a reformer in the new building materials industry and a practitioner of green space, Anbian advocates the concept of systematic fire protection, takes fire protection upgrading as a strategic focus, and develops a variety of building fire protection system solutions, such as curtain wall fire blocking, steel structure fire protection wrapping, ventilation duct fire protection products and firewalls, with ankuang board as the core.

The performance is stable, and the service life of the plate is very long, which can be the same as that of the building.

It is applicable to the base liner of various finishing materials (PVC, PP film, wood veneer, metal, ceramic tile, etc.) to replace the traditional wooden fire-retardant board to achieve class a fire prevention, environmental protection and formaldehyde free.

It is not only high ignition point, but also resistant to burning and deformation.

It can be widely used as interior decoration materials for education, residence, commerce and medical space, and is suitable for partition wall and wall system with fire prevention and sound insulation requirements.

Unlike other cement-based materials, ankuang board is an inorganic material.

Strive to use about 10 years to make the proportion of precast buildings in the new construction area reach 30%.

Material characteristics help the assembly application.

Ultra light and high strength, with surface density of 12.8kg/m2 and flexural strength of 13.97mpa, it can provide ultra-high strength while ultra light plate weight.

The single board sound insulation can reach 34dB, and the system sound insulation can reach 45-55db.

The ultra-low dry shrinkage rate and wet expansion rate can effectively ensure the stability of the plate in various environments.

It can be applied to various fields of precast building decoration, forming a fire-proof system, ankuang decorative panel A series of decorative building materials that meet higher fire safety standards, such as ankuang metal plate and precast partition wall, provide a new choice for the precast decoration of building space in the future.

The sound insulation performance is good.

It uses natural minerals as raw materials, focuses on the mineral fiber core layer, and endows the core of product technology with the core of minerals.

To help achieve the goal of “double carbon” at an early date in September 2016, the general office of the State Council issued the guiding opinions on vigorously developing precast buildings (GBF [2016] No.

We will build a standardized design and production system for precast buildings, promote the intelligent upgrading of production and construction, expand the use scale of standardized components and parts, and improve the comprehensive benefits of precast buildings.

Recently, anbi’an new materials group, a member of the precast building and green development branch of China Building Materials Industry Economic Research Association, has creatively developed a new multi-element magnesium based fire-proof material – ankuang board, which is composed of magnesium oxide, a variety of inorganic salts, reinforced glass fiber and polymer materials.

The patented fireproof building material ankuang board is made of a multi-element magnesium based cementitious system and produced through the mesh laying and pouring process.

There is no need for secondary processing for on-site installation, so as to realize the real precast building decoration.

In 2022, the Ministry of housing and urban rural development issued the “fourteenth five year plan” for the development of the construction industry, which requires the vigorous development of precast buildings.

It actively responds to the national demand for the industry’s low-carbon sustainable development and the concept of green environmental protection, and is committed to meeting the demand for high-quality green new building materials for public decoration, home decoration and municipal construction through technology and service innovation based on the three production bases in South China, East China and North China, guiding the reform of the construction industry and providing more possibilities for the future of architectural space.

It is a perfect choice for wall top lining plate.

Anbian new materials group is a high-tech enterprise driven by scientific and technological innovation to intelligently create a new green building material system of low-carbon, environmental protection, fire protection and sound insulation.

The quick installation partition wall system of Anbian completely uses Anbian’s own inorganic fire-proof materials throughout the production cycle.

In the three links of raw material production, finished product manufacturing and product sales, the lean production management mode has been introduced, which is fully automated production.

It has developed and manufactured Anbian fire and sound insulation door system, ANPIS quick installation partition wall series, ANPIS keel dry hanging partition wall series, ANPIS quick installation ceiling series, ANPIS quick installation wallboard series, curtain wall interlayer plugging, etc, It has obtained more than dozens of invention patents and dozens of utility model patents, edited and participated in editing more than ten group and industry standards..

No formaldehyde emission, no smoke toxicity, waterproof, sound insulation, is an inorganic green environmental protection board.

The high-strength density can be 1200kg/m ³。 This new type of plate can be produced at normal temperature, which changes the traditional process of building materials production in the past (such as ancient firing or steaming high temperature and high pressure process), effectively reduces the proportion of carbon emissions, and conforms to the national “double carbon” policy.

71), which proposed to develop precast concrete structures, steel structures and modern wood structures according to local conditions.

With ankuang board as the partition wall and Anxian fiber and ankuang high-strength materials as the keel frame, the finished product production is completed at the factory end.

Industrial production of finished partition wall in order to help achieve the goal of “double carbon” as soon as possible, ambian is also actively exploring energy conservation and consumption reduction in the production process, trying to further reduce labor costs and reduce carbon emission indicators through comprehensive upgrading of the production process.

The flatness is high, the tolerance is lower than the construction convenience, the impact resistance and flexibility are super high, and the on-site handling loss and construction damage are reduced.

It is mould proof and humidity resistant, with no reduction in strength and deformation in wet environment, and has excellent antibacterial and mould proof effect, so as to avoid indoor allergic environment caused by mold growth.