New decoration technology — what are the anti leakage means of precast toilet?

2.

Under normal procedures, a toilet can be installed in about two days, saving labor cost and improving efficiency.

1.

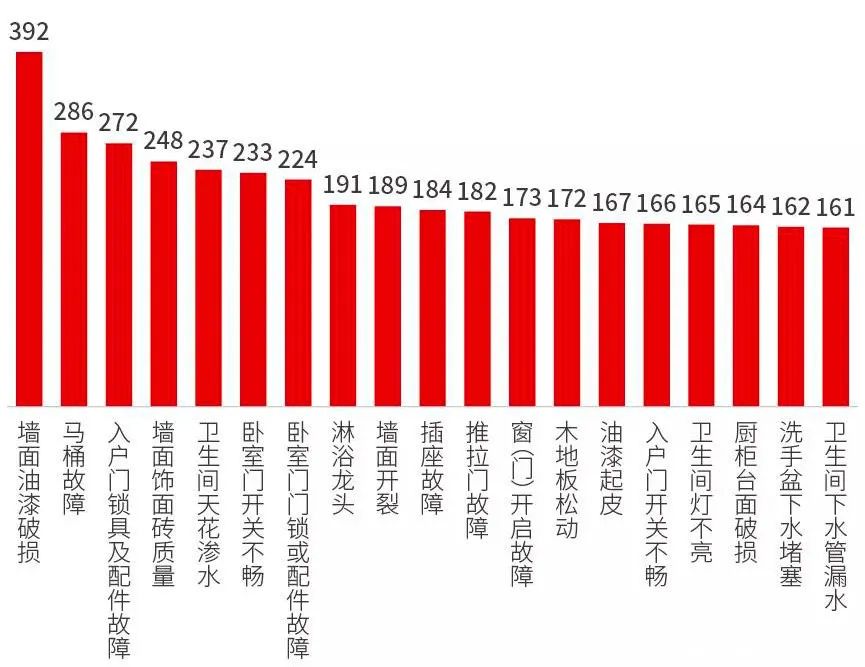

Behind the hot market is the high rate of complaints about fine decoration delivery.

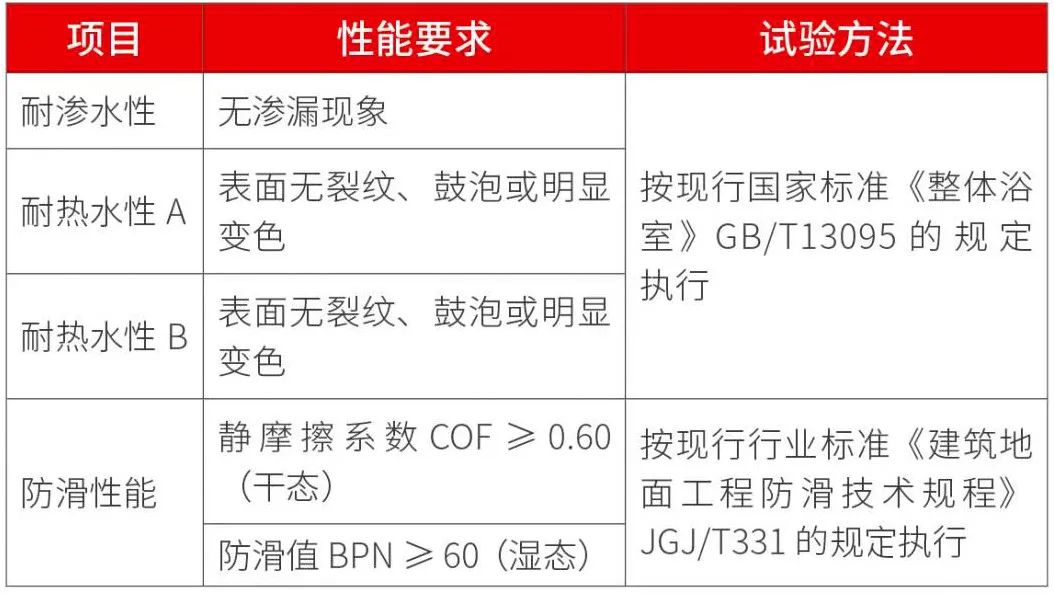

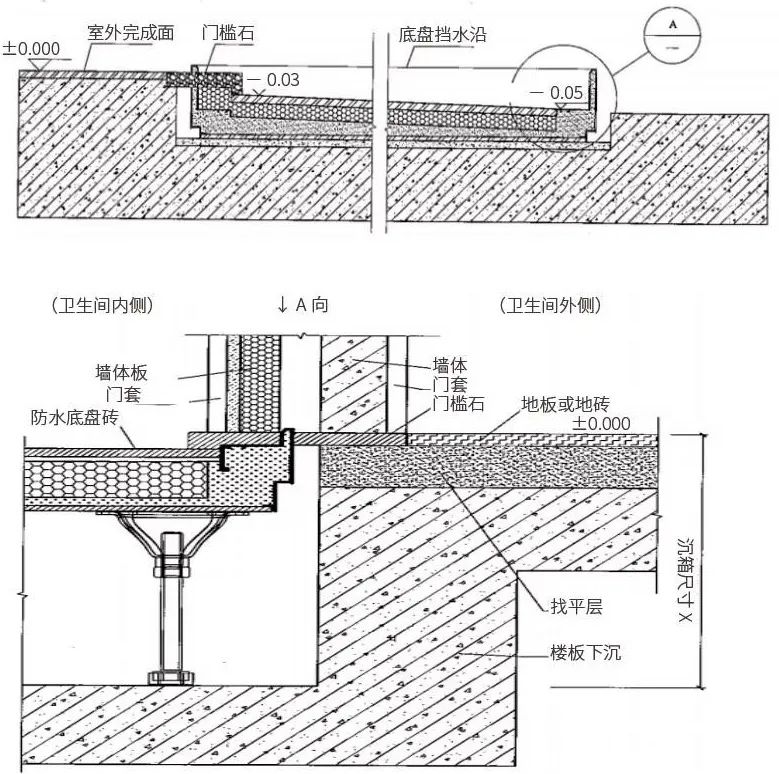

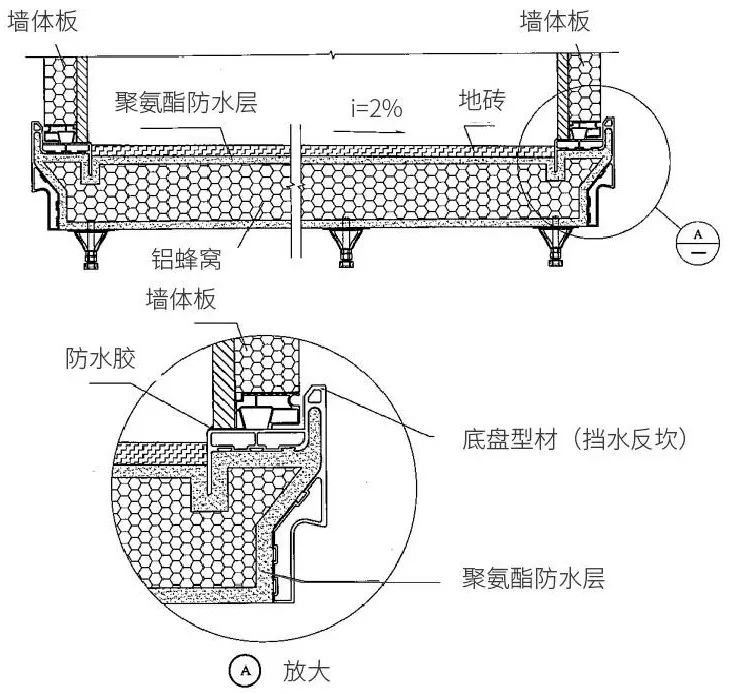

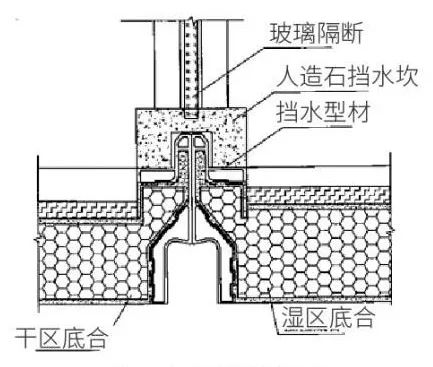

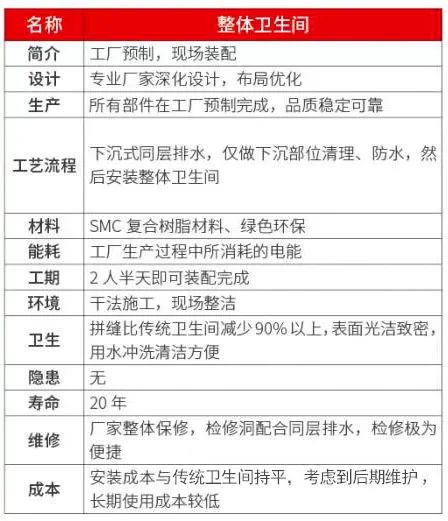

Structural diagram of waterproof chassis △ performance regulations of waterproof plate △ at present, domestic cast integral toilets are divided into SMC color steel plate system, honeycomb aluminum plate system, polyurethane foam system and GRC aluminum zinc plated keel system according to materials.

The key cast toilets are constructed by structural waterproof dry method.

The pipeline connection is convenient, simple and fast.

The precast overall toilet plays a very important role in the precast buildings.

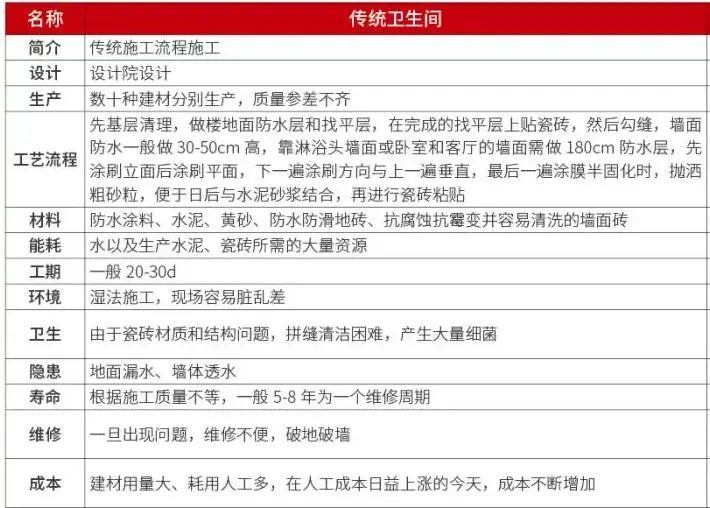

Construction comparison between the cast toilet and the traditional process toilet.

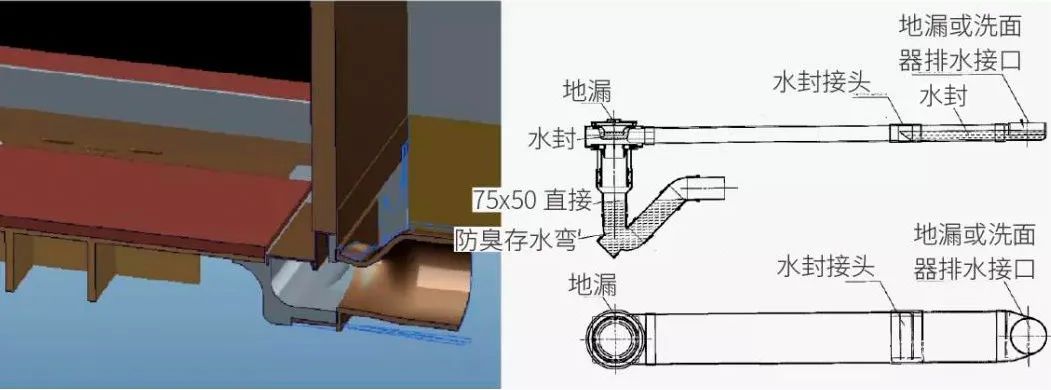

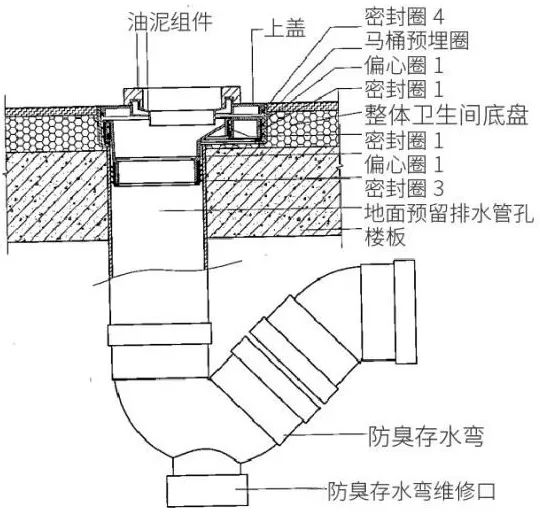

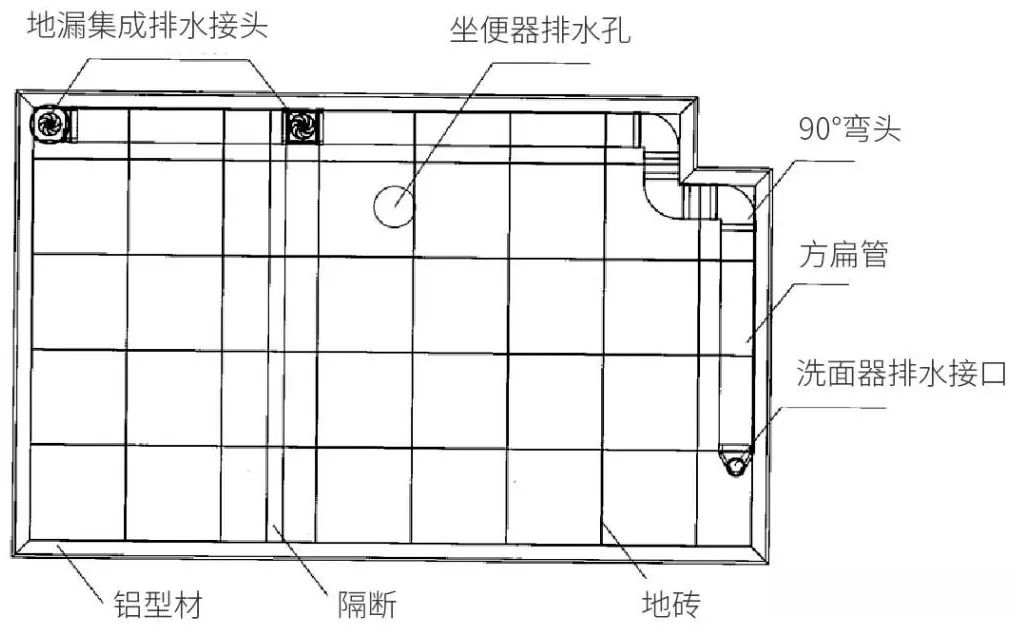

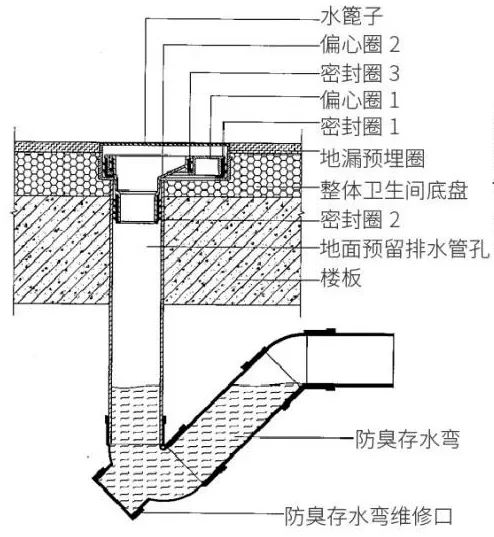

Floor drain drainage structure: according to the site construction conditions, the cast toilet has two drainage modes: the same floor drainage and different floor drainage.

The performance of the waterproof plate shall comply with relevant regulations.

Structural drawing of integrated drainage of waterproof chassis △ embedded construction method is adopted for the drainage pipe through the floor fittings of non falling plate assembled integrated toilet, and the subsequent dry construction method is adopted to improve the construction efficiency.

Hardbound house repair can not only improve the construction quality and help realize the industrialized production of residential decoration, but also bring a premium and become a new profit growth point.

The waterproof plates under different systems are different.

Precast buildings have a good development trend in China.

There are three main leakage risks: floor drain and drainage; Internal corner connection of wallboard and chassis; The connection between toilet and lintel.

The waterproof chassis has its own floor drain and drainage interface, the outlet is oval, and is equipped with a soft adjustment device, which can realize the rapid connection between the chassis’s own interface and the integrated water seal interface of the drainage collector in any direction..

For most real estate related enterprises, this is both an opportunity and a challenge.

The differences between the waterproof panels under the four systems △ 02 installation process of the cast toilet 1.

If the same floor non falling plate is used for drainage, the drainage collector (integrated water seal) shall be embedded in advance, the dry and wet floor drain and washbasin shall be connected to the integrated water seal, the rear drainage toilet shall be discharged separately and connected to the riser, and the collecting water seal shall be provided with an emergency ponding discharge port.

01 application prospect of precast integral toilet with the promotion of national policies related to environmental protection and green buildings in recent years, more than 30 provinces and cities have issued special guidance and relevant supporting measures for precast buildings to support the development of relevant industries.

The assembled toilet is composed of waterproof plate, wall plate and top plate.

Leakage has become a quality pain point and a hot issue in recent years.

The advantages of the cast toilet compared with the traditional process toilet are as follows: ① the cast toilet adopts an integrated chassis to effectively prevent leakage and improve the anti leakage safety of the sanitary room; ② Factory standardized production of structural accessories, strong controllability and guaranteed quality; ③ Due to the standardization of customized production and the improvement of material utilization, there is almost no construction waste for on-site assembly, which is energy-saving and environment-friendly; ④ Only two people are required for on-site assembly.

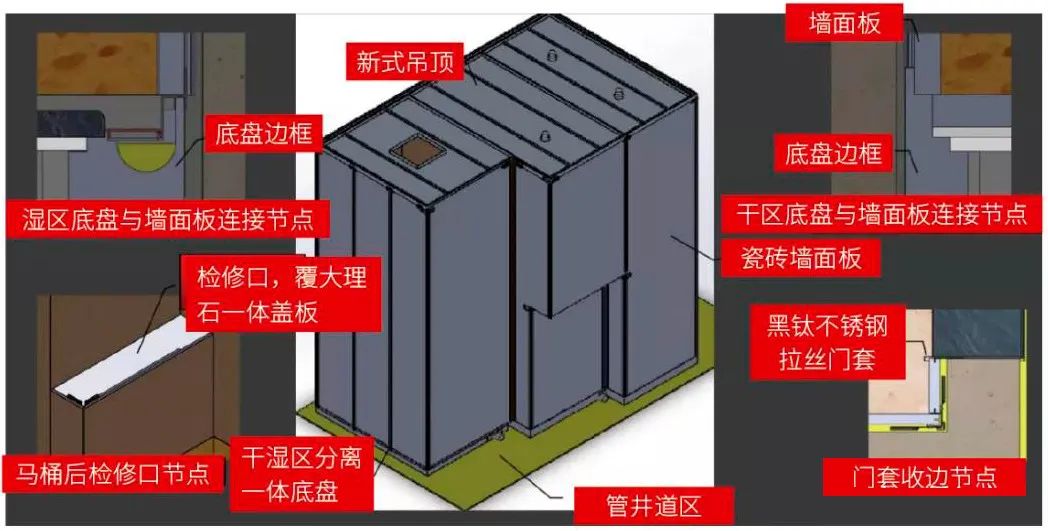

Relevant policy documents △ analyze the key points of leakage prevention and control of the process from the perspective of new technology of precast toilet: the main frame of precast integral toilet is composed of waterproof plate, wall plate, top plate and supporting keel, which is combined with various sanitary ware and functional accessories to form an independent bathroom module assembled and installed through on-site assembly or overall hoisting.

The height difference design is adopted in the shower area, which has the function of dry and wet separation.

Corresponding to different building schemes, the same floor drainage can avoid the property right dispute caused by crossing the floor, reduce noise and facilitate maintenance.

The Ministry of housing and urban rural development has formulated the detailed scoring table of precast buildings in the national standard of scoring standard for precast buildings, which stipulates that the score of the overall toilet accounts for as high as 6%.

Integrated toilet local structure △ the waterproof plate is made of special materials, which can achieve no difference in door frame.

The bottom plate component with waterproof, anti-skid, anti leakage, drainage and bearing functions is an important part of the overall toilet.

In recent years, there have been nearly 10000 complaints about leakage in fine decoration projects △ combined with the application of new construction technology in the decoration industry, this paper will explore the means of leakage prevention and control of precast integral toilet in waterproof engineering in fine decoration projects.

The 2167th day of learning with you in Xinzhu classroom, from the perspective of relevant national policies and the sustainable development direction of energy conservation, water conservation, material conservation and environmental protection in the construction industry, the fine decoration delivery of commercial housing is the general trend.

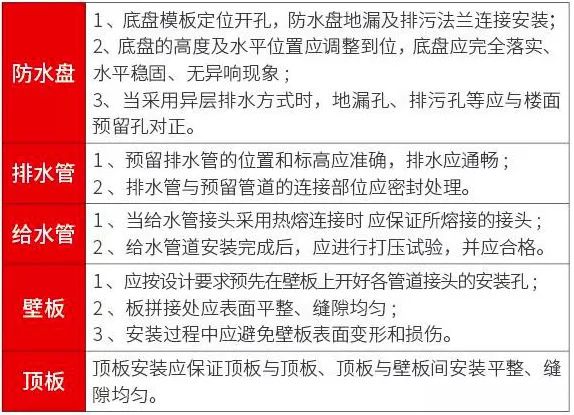

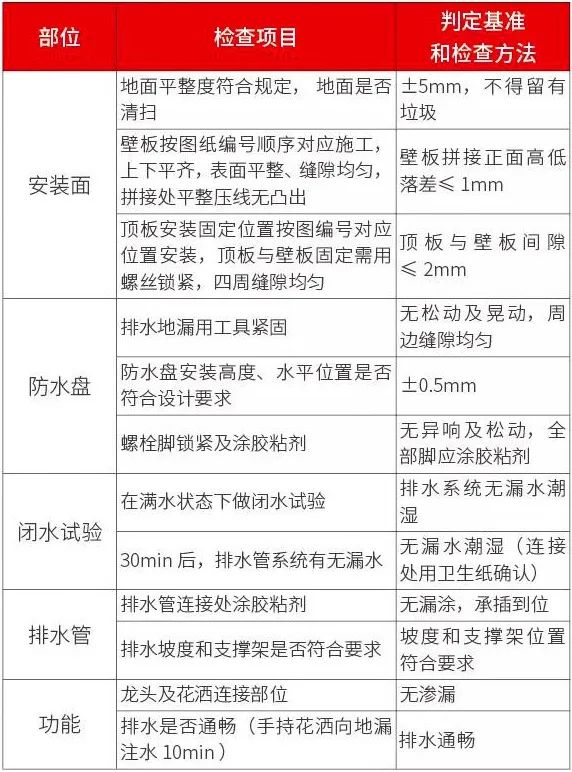

Attention should also be paid to relevant requirements during the installation of various parts: the installation of various parts requires △ 03 leakage prevention and control of cast toilets.

Only the aesthetic joint filling of ceramic tiles is required after the installation of ceramic tile panels.

Installation sequence of on-site cast integral toilet: ① determine the elevation of waterproof plate according to the design requirements, then install waterproof plate and connect drainage pipe; ② Install wall panels and connect pipelines; ③ Install the top plate and connect the electrical equipment; ④ Install closing of doors and window sleeves; ⑤ Install internal sanitary ware and functional accessories; ⑥ Cleaning, self inspection, inspection application and finished product protection.

It is expected that precast buildings account for more than 20% of new buildings, It accounts for more than 30% of provincial and municipal buildings and more than 40% of indemnificatory housing projects.

After the deviation of embedded parts, there is a riser positioner; The horizontal drainage branch pipe is constructed after the waterproof chassis is installed.

The waterproof chassis has no holes to prevent leakage.

Traditional craft toilet: ① due to the uneven construction level of on-site workers and management level of management personnel, and poor controllability of project quality, it is difficult to meet the requirements of specifications and standards, affecting the safety of anti leakage; ② The construction mode adopts on-site waterproof construction, on-site pouring of protective layer and on-site wet operation, and there is a large amount of construction waste in production; ③ Due to the great influence of natural factors and construction procedures, all professional departments cannot carry out cross construction.

There is no need to do any waterproof construction on the construction site.

Dry construction.