Observe the green campus demonstration project of the Ministry of housing and urban rural development: “precast + BIM application + green

2、 Innovative design of fully assembled structural system design for teaching buildings, teachers’ apartments and other buildings, innovative design and implementation of fully assembled concrete structural system, breaking through the traditional design methods of partial prefabrication and partial cast-in-situ, and using precast components from positive and negative zero to solve the assembly problem of mixed prefabrication and cast-in-situ, The whole assembly design system of concrete structure building with prefabrication and assembly as the core is established.

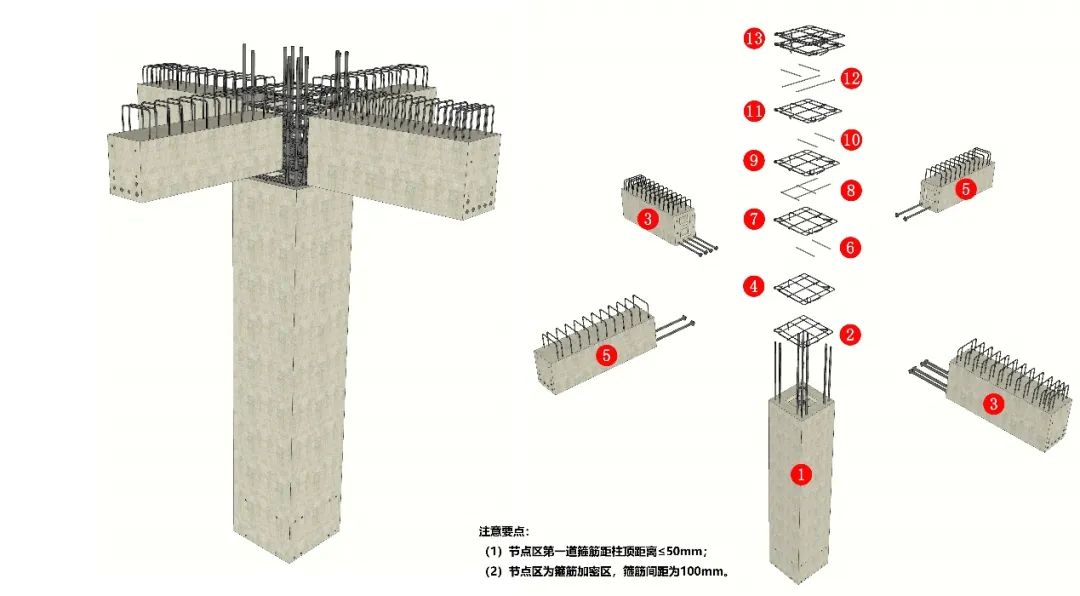

Among them, the teaching building, student dormitory and teachers’ apartment adopt the fully precast frame structure system, and the precast parts include precast columns, composite beams, composite floors (including roof slabs) and precast stairs; The concert hall and gymnasium adopt the composite structure system of “beam column joint steel sleeve + long-span steel beam + laminated plate and reinforced truss floor support plate”; ALC light partition wall is adopted for the wall to fully realize the integration of thermal insulation and wall plastering free.

The precast column details show the beam column joint effect, the superposition beam hoisting effect and the binding effect of stirrups in the core area.

Innovative design: starting from the first floor, all precast beam and column reinforcement are designed with large diameter, large spacing and small number.

At the same time, the industrialized construction method transfers most wet operations to factories, effectively reduces the discharge of harmful gases and sewage, reduces construction dust and noise pollution, and reduces the discharge of solid waste, which is conducive to environmental protection; Significantly reduce the labor intensity of workers and the incidence of safety accidents; Improve the construction speed, improve the construction quality and ensure the efficiency of safe and civilized construction.

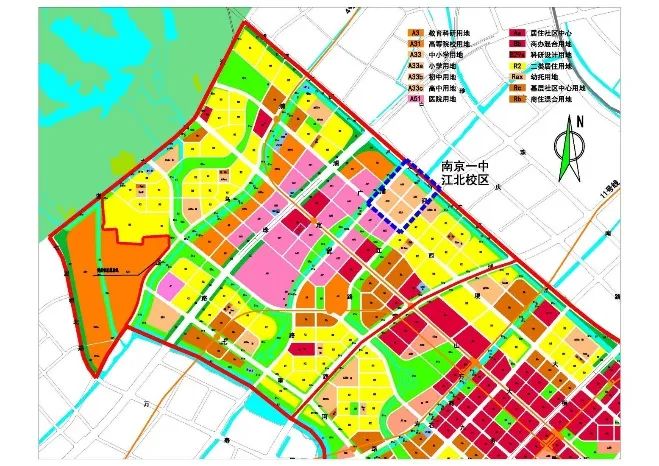

1 middle school (High School Department) will build a high standard boarding high school with 14 track system and 42 classes according to the positioning standard of “international famous and domestic first-class”, which will be used as the high School Department of Nanjing No.

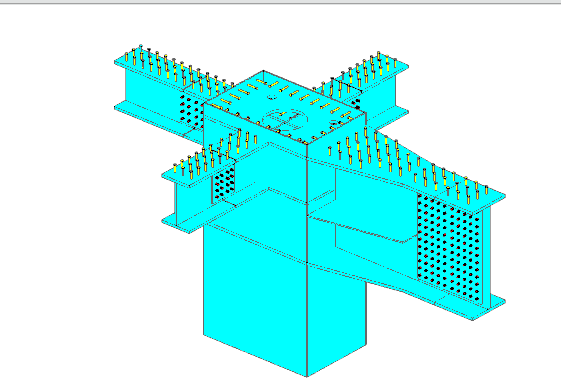

Give full play to the material characteristics of concrete compression, high stiffness, steel structure tension and convenient bolt assembly, make full use of the mechanical properties of materials, significantly reduce the beam section size, not only save the amount of steel and concrete, but also reduce the beam height, increase the clearance and reduce the floor height; The laminated plate and floor bearing plate are free of formwork system, which can effectively reduce the beam height and self weight; Reduce the number of component hoisting, so as to save the power consumption of tower crane, reduce the formwork support of prestressed beam and horizontal plate, and greatly improve the assembly efficiency and benefit..

For the collision of post cast joint reinforcement at the connection between precast beam and column components, the design technology of large diameter, large spacing and small number of beam and column reinforcement is innovatively applied to ensure the connection stiffness of reinforcement and realize the effective coordination of beam and column reinforcement, Improve construction efficiency.

At the same time, the project also undertakes four 13th five year plan topics such as “6.4 demonstration of key technologies for efficient construction of precast industrialized buildings” of the Ministry of science and technology of the people’s Republic of China, and is committed to building a green campus, a century old building and a national first-class high-quality project.

Conventional design: the first floor is cast-in-situ, and the subsequent floor is precast.

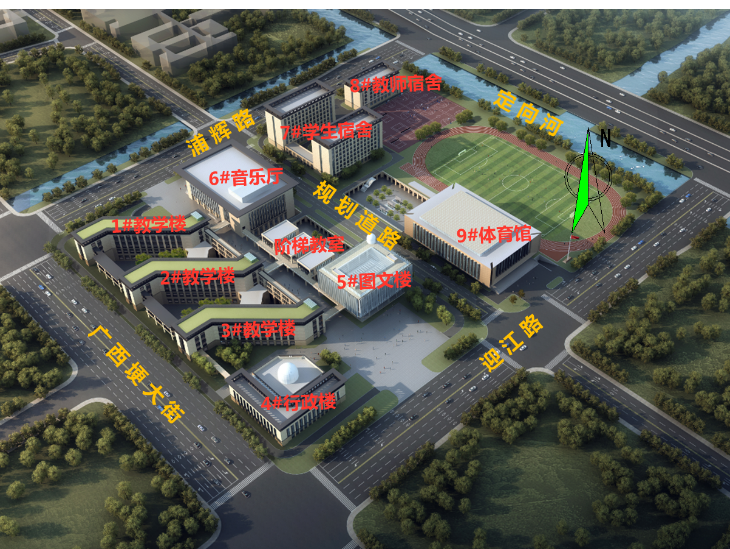

The project has 11 single buildings, including teaching building, dormitory building, picture and text building, gymnasium (open to the outside world) and Concert Hall (open to the outside world).

The design method of non reinforcement and close fitting of plate joints of laminated plates.

It is a fully precast structure, with a maximum prefabrication rate of more than 50% and a prefabrication and assembly rate of more than 60%.

1 middle school (High School Department) Jiangbei campus of Nanjing No.

The traditional laminated plate with reinforcement does not have reinforcement and the plate joints are closely jointed, which avoids the later formwork erection of the plate strip and plate joints in the traditional cast-in-situ area, reduces the process and shortens the construction period; Improve the efficiency and accuracy of on-site hoisting and installation; It is convenient for the factory to produce non reinforced laminated plates.

1 middle school in the future.

It is internally divided into East and West plots by an urban road.

In the design stage, the standardization of laminated plates is realized through “unchanged standard layer and unified bay”, which is convenient for factory production and improves on-site construction efficiency.

In the middle, the campus is connected into a whole through a sinking channel.

Aiming at the problem of low production and assembly efficiency caused by reinforcement of conventional horizontal plates, the design method of non reinforcement of laminated plates is innovatively adopted to facilitate the efficient placement of molds and improve the production efficiency of laminated plates; Aiming at the traditional separation connection mode of laminated floor, the design method of slab joint close fitting is innovated, which avoids the problems of low production and assembly efficiency caused by excessive reinforcement and reserved post pouring of slab joint under the traditional connection mode.

Through technical measures such as reinforcement equal strength replacement, reinforcement sleeve connection and pier head anchor connection, the complexity of reinforcement at the joint connection position is solved, the collision and conflict of reserved steel bars between components during hoisting are effectively reduced, the bending of reinforcement at the upper part of the beam is avoided, the anchorage length is reduced, and the use of steel is saved, Reduce the construction difficulty, realize efficient assembly and speed up the construction progress.

For the long-span structure of concert hall and gymnasium, the structural form of “cast-in-situ concrete column + beam column joint steel sleeve + long-span steel beam + laminated plate and floor bearing plate” is adopted.

The campus covers an area of 150 mu, with a total construction area of 107728 m2.

The teaching group is distributed in the West plot, and the living and sports area is distributed in the East plot.

Construction concept the first “green campus demonstration project of the Ministry of housing and urban rural development” and “green technology demonstration project of the Ministry of housing and urban rural development” in Jiangsu Province are built by China Construction Technology Group Co., Ltd.

The campus has 8 floors above ground (the highest), 1 floor underground (local mezzanine), and the building height is 30.4m (the highest).

The fully assembled concrete structure system is realized through the design of axial compression ratio control, connection strengthening design technology, structural form layout rules and seismic performance design technology.

in the way of integration of design and construction, using the new construction technology and new concept of “precast building + BIM application + green building”.

Break through the routine, adopt precast components in large quantities from the first floor, reduce the processes such as reinforcement turnover processing, full frame formwork system erection and formwork turnover processing, and shorten the construction period; Reduce the use of cast-in-situ construction formwork, concrete, water and other resources of first floor components.

The laminated plate has no reinforcement, reduces the difficulty of mold opening, improves the reuse rate of mold, effectively reduces the production cost of laminated plate, and is conducive to the promotion of industrialization.

The design system of cast steel-concrete composite structure adopts the innovative technology system of composite floor.

1、 Project introduction Jiangbei campus of Nanjing No.