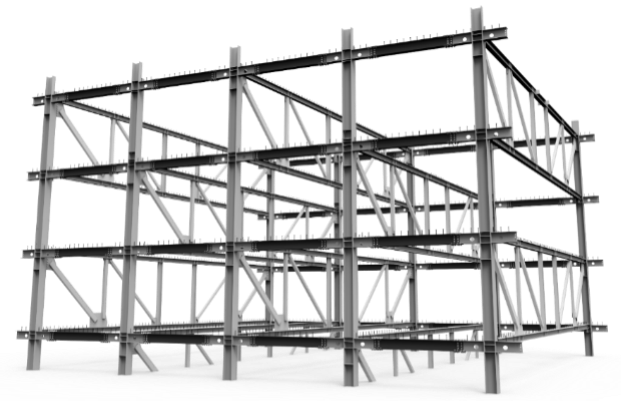

Precast building | “advanced, mature and applicable new technology” Introduction – precast steel frame staggered truss structure system

Fig.

3.

1 Technical content the cast steel frame staggered truss structure system is composed of frame columns, horizontal plane trusses and floors.

The columns are arranged on the periphery of the house without middle columns.

integrated integration technology: realize the integration technology of staggered structure and building maintenance system, equipment system and decoration system, especially the integration technology of truss and internal partition wall to solve the problem of fire prevention of steel structure and integration of pipeline, so as to reduce the amount of fire-proof coating and secondary cutting at the construction site, reduce dust and realize green construction; 3.

At present, steel frame structure, steel frame supporting structure, steel frame steel plate shear wall structure, etc.

1 isometric drawing of staggered truss due to the characteristics of spatial stress coordination of staggered truss structure, the floor participates in the overall calculation of the structure under the horizontal force generated by earthquake or wind load.

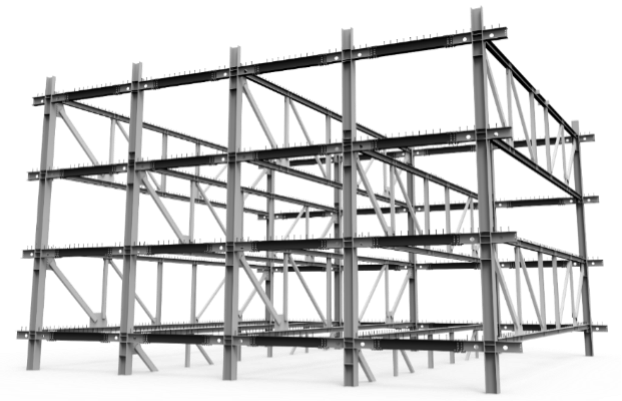

Fig.

During the construction of staggered truss, when the column, truss, beam, support and other large components are installed, they should be corrected and fixed by units to form a space stable system.

The truss mid span section can be made into a rectangular door opening without diagonal web members, and a corridor can be set or connected to adjacent rooms.

It can form a large bay with twice the column spacing, and obtain a large bay and depth in the architectural function, which is convenient for free layout.

The deviation of the shape and geometric dimension of truss fabrication shall comply with the design requirements and relevant provisions of the current national standards code for acceptance of construction quality of steel structures gb50205 and technical specification for steel structures of high rise civil buildings jgj99.

Combined with automatic welding equipment, the automatic production of staggered truss structure is realized; 4.

The structure of staggered truss mainly includes steel column, plane truss and frame beam.

Along the height direction, the truss is staggered on the adjacent frame columns.

Both ends of the truss are supported on the peripheral frame columns.

In addition to meeting the quality standard of steel structure, the steel members shall focus on ensuring the accuracy of plane truss, adopt standardized formwork for processing and manufacturing, and take measures to ensure that there is no deformation outside the truss surface during transportation.

industrialized production of staggered truss structure; The steel column adopts hot-rolled H-shaped steel column, and the truss web member adopts finished rectangular steel pipe.

2.

During the installation of the floor slab, the symmetrical hoisting method shall be adopted to prevent the stability problem during the out of plane construction of the truss.

4.

high construction efficiency: all nodes are connected by bolts, and the construction is convenient; 7.

good space removability: it can realize the single span structure without column in the middle, which is convenient for later building transformation; 6.

3.

scope of application staggered truss structure is applicable to multi-storey and high-rise buildings with regular plane of apartments, hotels, dormitories, hospitals and other buildings in areas with seismic fortification intensity of 6~8 degrees.

Source: precast steel frame staggered truss structure system of China Architectural Society recommended by: Zhejiang Lvzhu Integrated Technology Co., Ltd.

technical advantages 1 Standardization of staggered truss structure: due to the unique stress characteristics of staggered truss structure, the specification of truss can be locked, so as to realize standardized production; 2.

technical indicators for construction and installation (1) the installation and construction organization design of staggered truss steel frame structure shall be carried out according to the requirements of design documents and construction drawings, and the steel structure shall be installed according to the construction organization design.

The height of the truss is the same as the floor height, and the length is the same as the width of the house structure.

One end of the floor is supported on the top chord of the truss, and the other end is supported on the bottom chord of the adjacent truss.

The characteristics of staggered truss structure are highly consistent with the needs of apartment buildings.

They use a large amount of steel and have a high cost, which can not meet the needs of high standardization of apartment buildings.

are almost adopted for apartment steel structure construction products.

good economic performance: 20% less steel and 30% less foundation; 5.

large structural stiffness and good comfort.

(2) The installation of staggered truss steel frame structure and the construction of floor shall be carried out successively, and the distance between the two operations shall not exceed 5 floors.

2 hoisting construction of truss 2 Technical index 1 Technical indicators in design (1) the design and construction of the technical system of staggered truss structure shall comply with the relevant provisions of the current national standards code for design of staggered truss steel structures jgj/t329, code for seismic design of buildings GB50011, standard for design of steel structures GB50017, etc; (2) The safety grade and design service life of the structure shall meet the provisions of the current national standards unified standard for reliability design of engineering structures gb50153 and unified standard for reliability design of building structures gb50068; Staggered truss structure shall be designed for bearing capacity limit state and normal service limit state; (3) composite beam effect should not be included in the analysis of vertical load of staggered truss structure; Composite beam effect should be taken into account in the analysis of transverse horizontal load of staggered truss structure; (4) The economic height width ratio of staggered truss structure should be 3~6, and the span of truss should not be greater than 21m; The span height ratio of truss should be 5~6; The longitudinal column spacing of the structure should be 6~9m; (5) when vierendeel truss is used in the design, the truss joint shall be designed as rigid joint, and the connection between truss chord and column shall be designed as rigid connection; When the mixed truss is adopted, the chord shall be continuous, and the connection between the truss web member and the chord, and the connection between the truss and the column can be designed as hinged.

The installation procedure must ensure that the structure forms a stable space system without causing permanent deformation of the structure.

Staggered truss, steel frame structure and steel frame supporting structure can be mixed to meet the specific needs of buildings..

In the design stage, the characteristics of floor coordination should be fully considered for overall analysis and calculation, and the deformation coordination between the floor and the main structure cannot be considered by using the traditional frame system theory, In particular, the anti-seismic structural measures and calculation review for the connection of floor slab and plane truss chord shall be considered.

after the production and manufacturing of technical index components is completed, the inspection department shall inspect and accept the finished products in accordance with the requirements of the construction details and the provisions of this specification.