Precast building 𞓜 characteristics and comparative analysis of precast decoration system

3) Part integration customization.

There are not many enterprises that can provide whole house assembly solutions.

2) The pipeline is separated from the structure.

Assembly type information production and standardized replication have realized the homogenization and expansion of decoration products.

At the same time, according to the statistics of the Ministry of housing and urban rural development, the construction area of newly started precast decoration in 2018 was 6.99 million square meters, accounting for 5.77% of the newly started fully decorated construction area; In 2019, the newly started area was 45.29 million square meters, with a year-on-year increase of 547.93%, accounting for 18.97% of the newly started fully decorated building area.

At the same time, because the life cycle of interior decoration is different from that of building structure, the former is 5-10 years, and the latter is 50 years, so interior decoration must face secondary transformation.

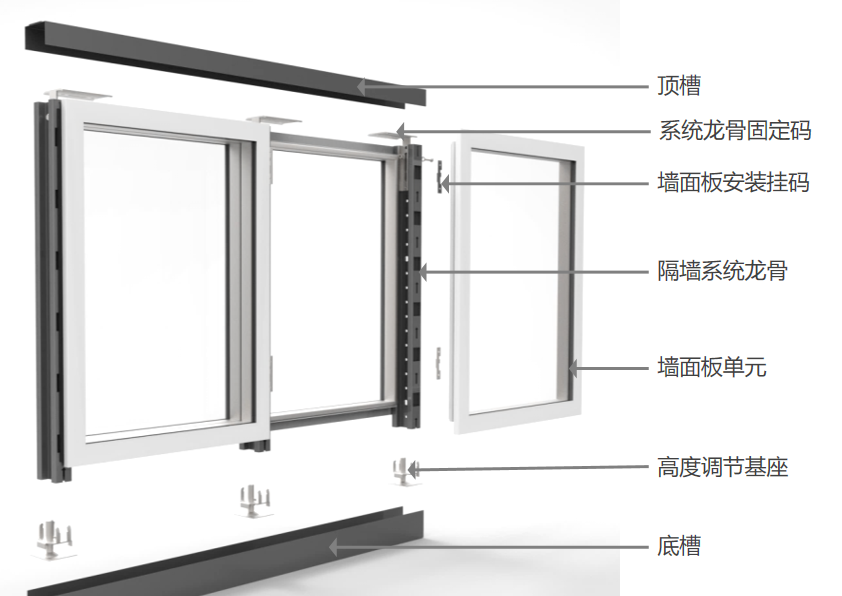

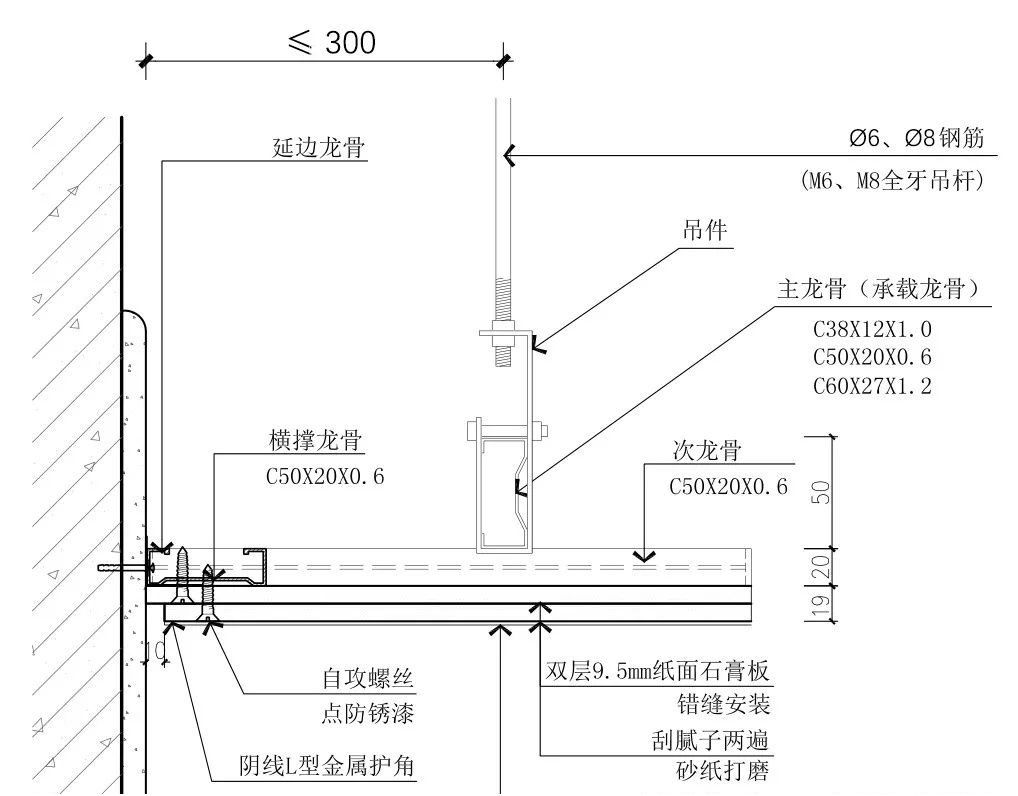

It can be seen from this that to judge whether the decoration method is assembly decoration, the following three aspects should be summarized from its technical characteristics: 1) dry construction method assembly.

It can be expected that the industry concentration will increase significantly in the future, and the “big market, small enterprise” pattern will also be rewritten.

In addition, due to the complexity of the decoration itself, at present, most decoration enterprises in China start from the assembly of components, such as Keyi integrated bathroom, Boloni home and Haier home.

According to the research of design and construction of precast decoration, the annual loss caused by the secondary decoration is more than 30billion yuan.

However, due to the combination of traditional decoration and main structure, it is inevitable to smash and chisel during transformation, resulting in a large amount of construction waste and environmental pollution.

The affordable housing is mainly used as a test field for precast decoration technology, with a construction demand of 10-20 million units per year..

Throughout the home decoration industry, it is still in the development stage of long chain, poor management level and low efficiency.

to realize the support and connection structure.

Assembly decoration is to directly hit the pain point and subvert the decoration industry from the bottom logic.

The circuit is widened and there are many participants, making the precast decoration closer to the needs of users.

Many leading enterprises are also expected to establish scale advantages and build a moat through rapid production expansion.

According to relevant research results, the number of deaths due to indoor pollution in China reaches 111000 every year, and 42.1% of the total number of newly added children with congenital disabilities is related to indoor air pollution.

Yasha has entered the field of precast decoration since its listing in 2012.

Many on-site construction processes and complex processes lead to many hidden dangers.

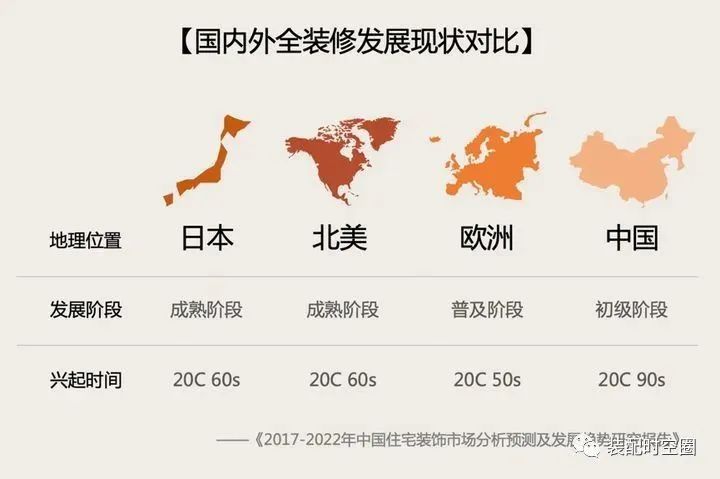

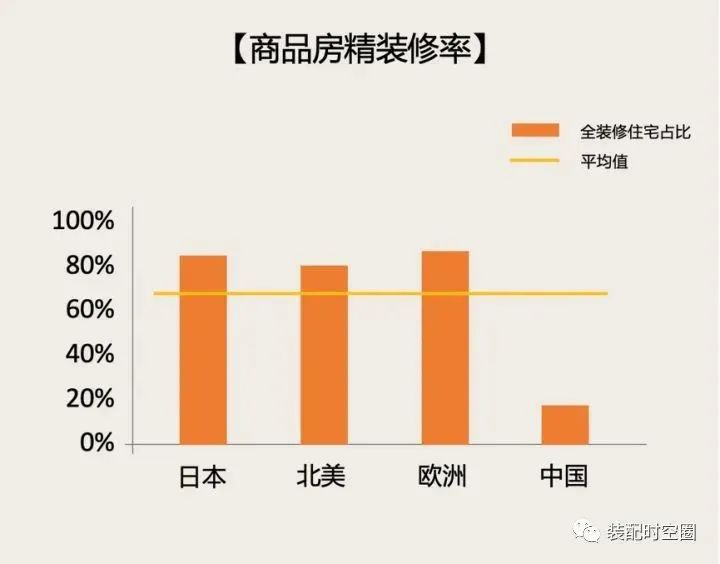

The proportion of fully decorated houses is about 20%, which is far lower than the level of 80% in Japan, the United States and other countries, which limits the application of precast decoration.

For example, Vanke has closely combined the precast building with the precast decoration scheme by creating a “5+2+x” industrialized construction system, that is, a five piece system (full concrete external wall, precast internal partition wall, system template, climbing frame, interspersed efficiency improvement) + precast decoration + appropriate prefabrication, which has effectively reduced the implementation cycle of the demonstration project and accelerated its own turnover.

1、 Concept assembly decoration, also known as industrialized decoration.

3) The decoration environment is seriously polluted.

4) Serious waste of material resources.

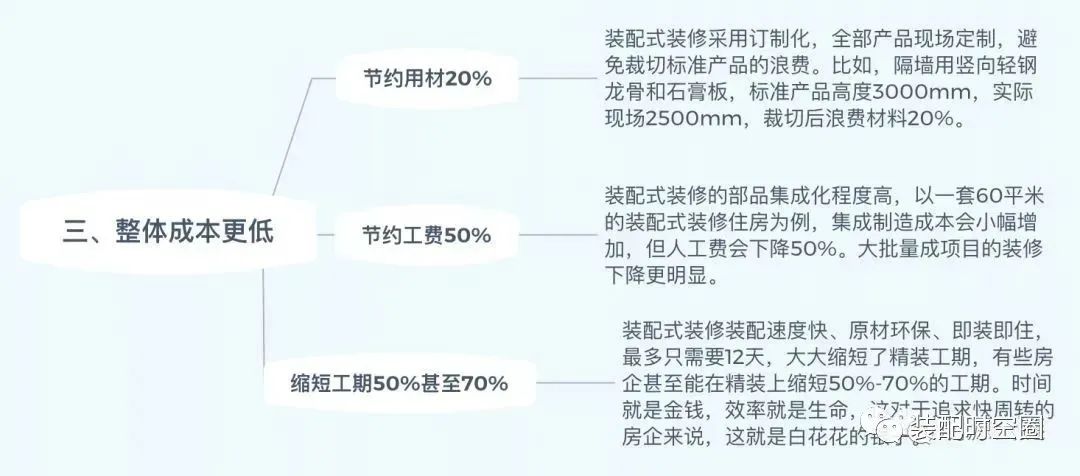

The pre positioning, standardization and industrialization of the decoration process have reshaped the industrial chain while improving efficiency.

Current situation of precast decoration precast decoration technology is currently mainly used in the decoration of affordable housing, long-term apartments and hotels.

Specifically: 1) there are many common problems in decoration quality.

The common problems of moldy walls, wet and powdered walls and peeling of wall tops in traditional decorated houses are caused by the difficulty in controlling the quality of traditional wet operation; Problems such as uneven ground and water and electricity pipe rupture are caused by poor construction accuracy.

Why should we vigorously develop precast decoration? The traditional decoration method has been prevailing in China for a long time, with many on-site links, many types of work, heavy reliance on manual operation, long time-consuming, difficult to guarantee quality and other shortcomings.

The heavy reliance on manual operation has become an important factor for the low entry threshold and poor competition pattern of the traditional decoration industry.

In 2017, the technical standard for precast concrete buildings and the technical standard for precast steel structure buildings issued by the Ministry of housing and urban rural development clearly gave the definition of precast decoration, which refers to the decoration method of combining and installing the factory produced interior parts on site by using the dry construction method.

2) There are many hidden dangers in the decoration process.

Development status of precast decoration in China at present, the development level of precast decoration in China is relatively low.

The prevalence of “decoration guerrillas” in China has obviously restricted the development of the decoration industry.

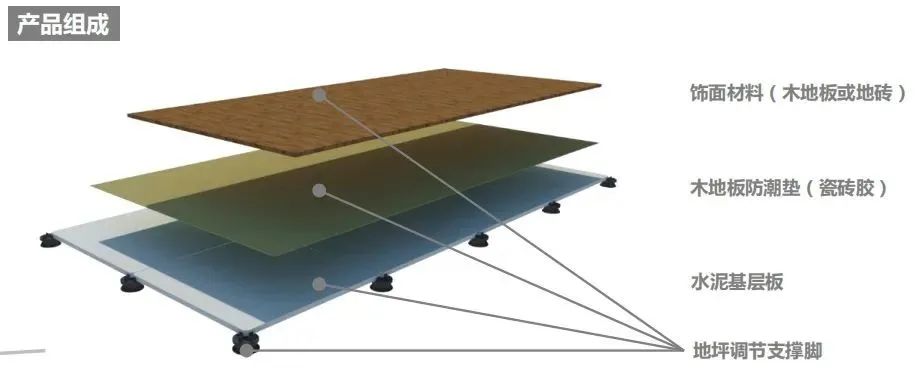

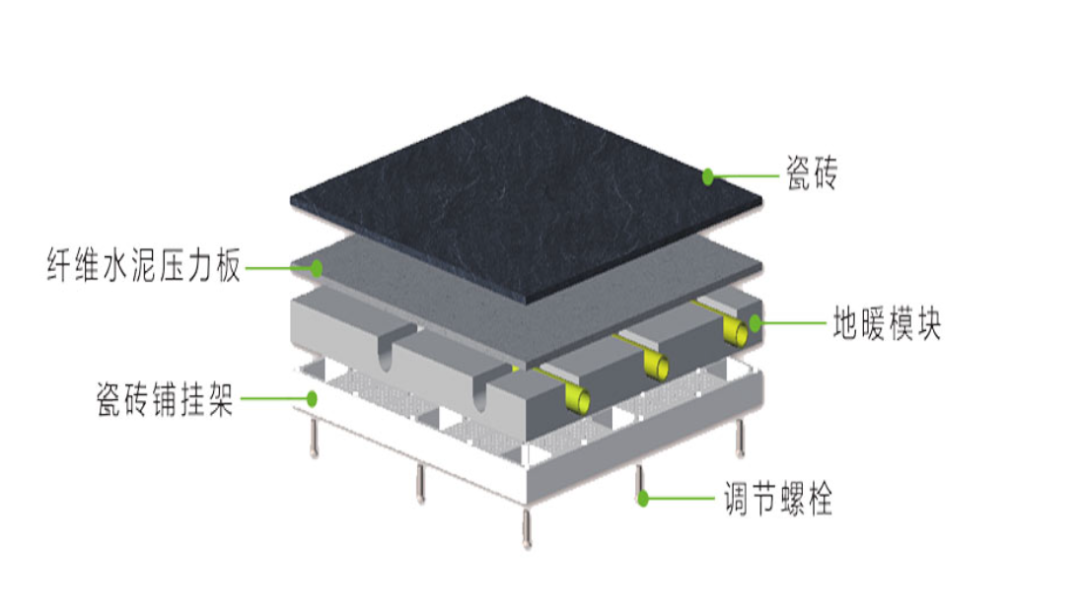

The so-called dry construction method is to avoid the wet operations such as gypsum putty leveling, mortar leveling, mortar bonding, etc.

A large number of houses delivered are in the form of blank houses or semi-finished houses.

The precast decoration has the industrialized thinking of standardized design, industrialized production, precast construction and information coordination.

The difficulty of on-site management has become the main obstacle for most decoration companies with limited management radius and difficult to break through the scale.

The content of formaldehyde in traditional decoration materials is high, which is easy to cause indoor pollution.

Component integration is to integrate multiple dispersed components and materials into an organism through specific manufacturing supply.

That is, the equipment and pipelines are not embedded in the building structure, but filled in the gap between the six sides of the cast space and the supporting structure.

As the traditional decoration will partially damage the protective layer of the main structure, wall chiseling and other behaviors are more likely to cause structural safety problems (such as the Quanzhou hotel incident).

used in the traditional decoration method, but to use anchor bolts, supports, structural adhesives, etc.

At present, the company has the highest number of precast decoration patents in the industry.

Traditional decoration uses a large amount of materials during the first decoration, and the secondary renovation causes a waste of materials.

The dry construction method is realized while the performance is improved, which is easy to deliver and assemble.

Part customization emphasizes that although the cast decoration is industrialized, it still needs to meet personalized customization, so as to avoid secondary processing on site.