Precast building | advanced, mature and applicable new technology: integrated toilet construction technology

They are “plug and play” molded products.

6.

Other standards and specifications to be referred to also include: Code for quality acceptance of residential interior decoration engineering JGJ / T304, sanitary ceramics GB / t6952, toilet cleaner JG / t285, code for construction quality acceptance of building water supply, drainage and heating engineering gb50242.

3.

Joint treatment: after the connection between the integrated toilet and the main air, water and power system pipelines of the building structure is completed, the gap between the bottom plate of the integrated toilet and the lower plate groove shall be grouted after passing the acceptance.

Interface connection: the stone surface, wall surface, ground and other contact parts of various sanitary appliances shall be sealed with silicone glue or waterproof sealing strip.

5.

The main construction processes of integrated toilet construction technology are as follows: 1 Process flow: Measurement and setting out → installation of equipment end and branch pipeline → chassis installation → installation of wallboard and accessories → installation of top plate and other parts → installation of internal equipment → interface connection → joint treatment.

The installation of chassis, keel, wall panel, doors and windows are connected with bolts, and the top cover and wall panel are connected with connectors.

Drainage on the same floor is adopted, and the pipeline connection is convenient.

At first, the whole bathroom was mainly used in engine room, hotel, hospital, fast loading house and other fields in the domestic market.

Installation of wallboard and accessories: first install the wallboard on the edge of the chassis, tighten the clip at the joint, and embed it with sealant at each joint; Install the bathtub, connect the water outlet and level the bathtub; Then install other wall panels and embed all joints.

The customized sanitary ware, electrical and hardware are connected with the chassis and wall panel by bolts.

3.

All decoration materials are precast and produced in the factory to form standardized and universal parts, which are delivered to the site for assembly construction on time, in accurate quantity and specification.

This technology does not include the integral toilet on high-speed railway, aircraft and ship.

Apply sealant at the joints of all plates and walls.

5.

The molded chassis is integrated to effectively improve the waterproof and leak proof performance.

The integrated toilet and precast building can be constructed at the same time, which provides an industrialized overall solution for the whole interior decoration of the residence.

The integrated design is adopted to carry out modular decomposition of all components in the house to reduce the proportion of on-site operation.

The basin under the table must be installed at the reserved hole on the artificial stone table in advance, firmly bonded with marble glue, and the joint shall be sealed with anti mildew sealant.

According to the new technological achievements submitted by enterprises, the construction industry modernization development committee of China Architectural Society has launched 21 advanced, mature and applicable new technologies after consulting experts.

4.

Chassis installation: install and fix the chassis and level it with fine-tuning bolts.

2.

Installation of internal equipment: place sanitary equipment according to the drawing design requirements and connect each pipeline interface.

Scope of application: the whole bathroom was first introduced into China in the 1990s.

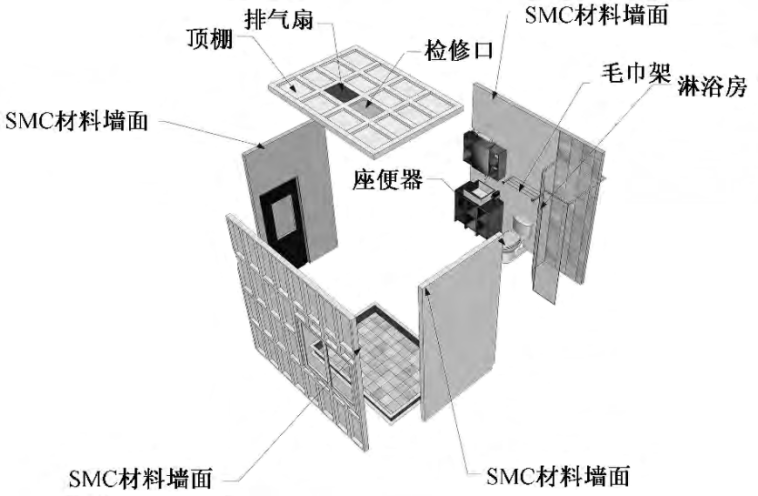

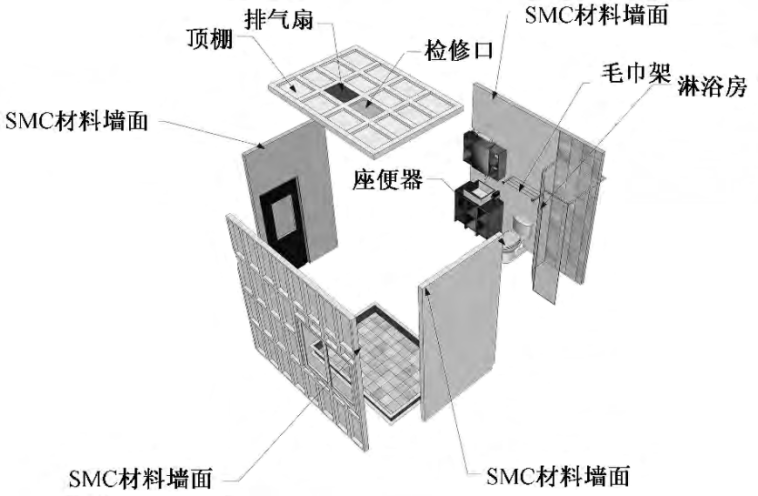

Figure 1 integrated toilet 2 The technical index “8.3 integrated toilet” in JGJ / t445 “coordinated standard for dimensions of industrialized houses” stipulates the design of integrated toilet.

The engineering example is applied to the electromechanical installation project of the R & D center of CSCEC Chengdu Green Building Industrial Park (phase I project)…

8.

5.

The water supply and drainage pipe shall be connected with the reserved pipe with special joints and glued.

Recommender of integrated toilet construction technology: China Construction Installation Group Co., Ltd Technical content integrated toilet refers to the toilet that is integrated by the floor, ceiling, wallboard, sanitary ware equipment and pipelines produced by the factory and mainly assembled by dry construction method.

It has the advantages of short construction period and controllable quality of precast building.

7.

Special steel clips are used to connect the bottom plate and wallboard, between wallboard and wallboard and between the top plate.

The standardization, modularization, industrialization and generalization of residential decoration parts are realized, and many contradictions and problems of traditional residential decoration are solved.

Installation of top plate and other parts: first install the top plates on both sides, then install the middle top plate, finally seal the top plate joint with plastic strip, and then install the door, doors and windows and fasten them with screws.

This issue introduces the construction technology of integrated toilet.

It carries out accurate production according to the given design and technical requirements under the condition of factory assembly control, so as to achieve optimal control in quality and cost.

4.

At present, in the construction field, it is mainly used in residential buildings, hospitals, express hotels and other civil buildings.

The floor drain pipe at the bottom of the chassis is connected with the sewage pipe with glue, and the floor drain and sewage pipe flange are installed on the chassis surface.

Installation of equipment end and branch pipeline: install water outlet, sewage pipe and pipe rack of water supply system.

3.

4.

Technical advantages 1 Separate and independent from the framework of the building to achieve good load-bearing support.

2.

A set of molded integrated toilet products include external frame structures such as top plate, wall plate and waterproof chassis, as well as internal components such as sanitary ware, hardware, ceramic tile, lighting and water, electricity and air system in the bathroom.

They can be assembled in hotels, residences, hospitals and other environments according to their use needs.

The bolt connection shall be covered with special nuts, and the outer ring shall be sealed with sealant.