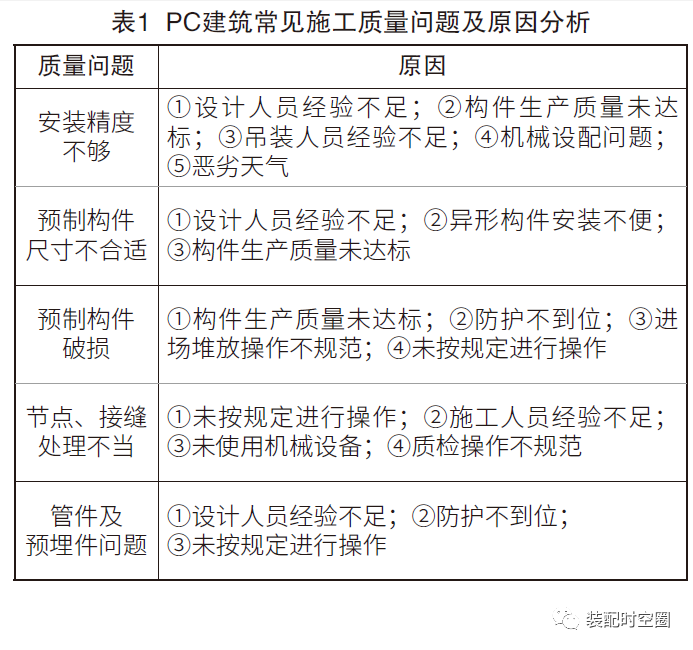

Precast building | research on common quality problems and control measures of precast concrete building

The main reasons are: (1) the designers are inexperienced and do not fully consider the problem of component conflict in the component splitting design; (2) The cost of mass production of some special-shaped components in the precast component factory is high and the production speed is slow, so they need to be cut and processed on site before installation; (3) During the production of precast components, the size of precast components is inconsistent with the design size due to loose quality control, instruments and equipment or production process.

With the support of national and local policies, it is now in great development.

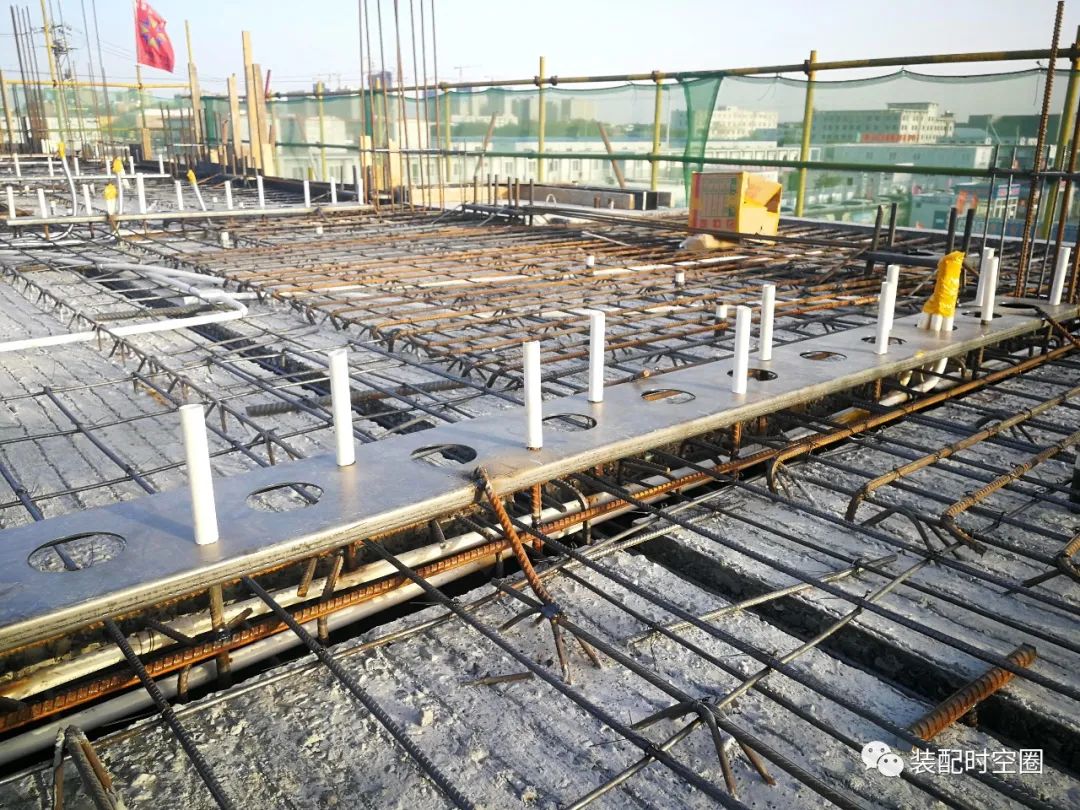

2.5 problems of pipelines and embedded parts the problems of pipelines and embedded parts at the construction site are mainly reflected in the blockage and displacement of embedded pipelines, the obstacles encountered in threading, and the falling off and displacement of embedded parts..

The specific performance on site is that the components are missing edges, hanging angles, cracks and even fractures.

The biggest difference between precast buildings and general cast-in-situ buildings is the different construction methods.

The inappropriate size of precast components is not only a lot of quality problems in PC building construction, but also a major reason for insufficient installation accuracy.

By combing the common quality problems and causes of precast buildings, looking for their control measures from their roots is a feasible way to solve this problem.

It is mainly reflected in the large joint error and different height between wallboards or laminated plates at the construction site.

The main reasons for improper treatment of joints and joints are as follows: (1) there are problems in the quality control of grouting materials, such as failing to configure according to the mix proportion, placing for too long and the slump does not meet the requirements; (2) Operators lack professional construction experience and are not skilled in grouting technology and joint treatment technology; (3) No special grouting machine is used, and manual grouting is directly used; (4) After the grouting is completed, the compliance testing instrument is not used to confirm its quality.

2.1.

The introduction of its unique process flow such as factory prefabrication and on-site installation has added new quality risk points.

2.3.

The main reasons are: (1) the production of precast components is not strictly controlled, the quality is poor, there are missing edges, hanging angles, cracks, etc.

Abstract: by combing the common quality problems in the construction of precast concrete buildings, analyzing their causes, this paper puts forward some measures to improve the construction quality of precast concrete buildings, such as improving the management system of precast buildings, implementing lean management, applying BM technology, supporting qualified and efficient construction machinery and strengthening the professional degree of employees, In order to provide reference and ideas for the quality management of precast buildings.

when leaving the factory, and the entry inspection is not in place; (2) The protection is not in place during transportation, resulting in excessive turbulence, resulting in component damage; (3) When the components are stacked on site, the ground is not hardened, resulting in uneven settlement, resulting in damage to the components; (4) The operators on the construction and installation site are not familiar with the construction process, and there are errors and illegal operations, resulting in the collision of components.

Its common manifestations on site are: insufficient grouting of grouting sleeve, insufficient joint strength, cracks at joints, weak connections and serious leakage in the later stage.

Prefabrication building has the advantages of high construction efficiency, good quality, low labor cost and green environmental protection.

Therefore, improving the construction quality management level of precast buildings and reducing the incidence of construction quality problems of precast buildings are urgent problems to be solved in the development of precast buildings and the realization of China’s construction industrialization.

Improper treatment of joints and joints.

Improper treatment of joints and joints is also the most common quality problem in PC buildings.

1.

2.2.

Its consequences on the construction site are mainly reflected in the large joint error and different height after installation.

At the same time, China’s precast buildings are currently in the development stage, have not yet formed a perfect design, production and construction installation system, the quality management process is not perfect, and there is a lack of perfect guiding documents and specifications, which brings challenges to the quality management of precast buildings.

Insufficient installation accuracy is a common construction quality problem of PC buildings.

In the development of precast buildings in China, there have been quality problems, which have been suspended for a long time.

2.

Quality management is an unavoidable problem in the development of precast buildings.

Damage of precast components.

Installation accuracy.

Joints and joints are the places where quality problems often occur in PC buildings.

The main reasons are as follows: (1) the designer is inexperienced and does not consider it fully when splitting the structure, resulting in the error of design size; (2) During the production of precast components, the size of precast components is inconsistent with the design size due to lax quality control, mechanical equipment or production technology; (3) Insufficient installation experience of hoisting personnel leads to insufficient installation accuracy; (4) Improper selection of hoisting equipment and long-term maintenance of equipment and instruments; (5) Bad weather during installation, such as strong wind, makes the component hoisting process difficult to control and installation deviation occurs.

For example, the workers do not use reasonable machinery, directly turn over the precast components or use the operating stick to shift, and the collision occurs during hoisting.

At the same time, there are serious conflicts between components, and some components need to be cut on site.

Common construction quality problems and analysis of precast buildings at present, the common construction quality problems of precast buildings mainly include insufficient installation accuracy, inappropriate size of precast components, damage of precast components, improper joint treatment, pipeline and embedded parts, etc.

Damage of precast components is also a common construction quality problem in the construction of precast buildings.

2.4.

With the gradual popularization and application of precast buildings, its quality control must be paid attention to.