Precast buildings: carbon neutral emerging Blue Ocean (with shares)

At this stage, the precast building technology system is more perfect, the component quality and construction technology level are greatly improved, and the common quality problems such as cracking and leakage are basically solved.

The R & D process of each architectural firm includes the R & D and assembly related products in the early stage, and the R & D process of each architectural firm.

The level of construction industrialization, digitization and intellectualization has been greatly improved, the green transformation of construction mode has achieved remarkable results, and the transformation of construction industry from large to strong has been accelerated, providing strong support for the formation of a strong domestic market and the construction of a new development pattern.

The midstream production link mainly refers to the manufacturing of precast components in the factory, which operates on the production line through formwork assembly, pouring and other processes, and mainly involves the manufacturers of various precast components.

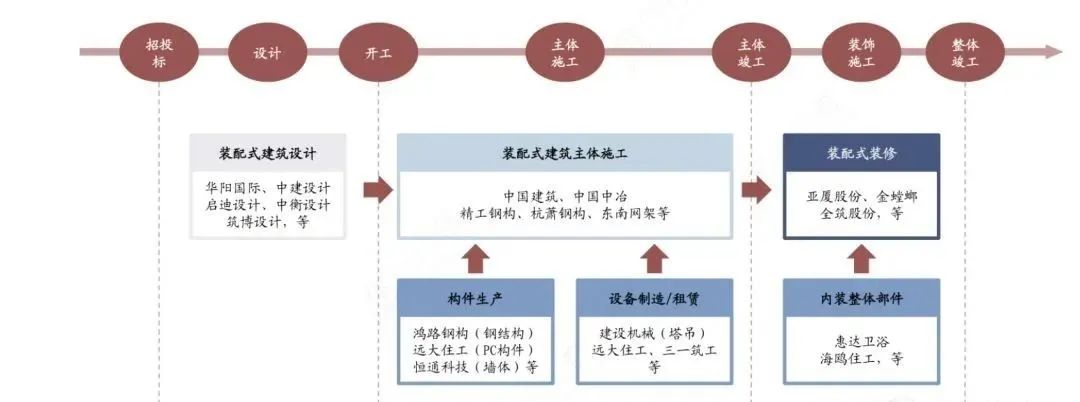

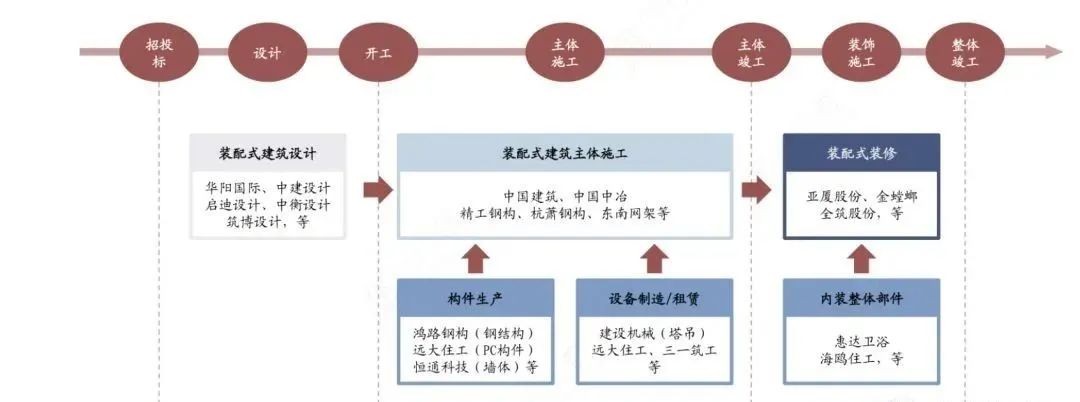

The upstream is architectural design and product R & D; Midstream includes manufacturers of concrete precast components, steel precast components and other components in the factory and contractors who assemble components on site; The downstream is the developer and construction operation and maintenance unit of construction projects.

In the long run, with the continuous improvement of the standardization degree of the precast construction industry, the growth space of the subdivided industry leaders focusing on the fields of design, production and manufacturing is broader, and the profitability can be continuously improved through large-scale advantages and fine management.

The production capacity of precast components is another key factor determining the development speed of precast buildings.

The fixed cost of this part will be greatly diluted, which will further reduce the total cost of precast buildings.

Main participating enterprises of precast buildings: Source: the 14th five year plan for the development of construction industry issued by the Ministry of housing and urban rural development of CSC proposes that precast buildings will account for more than 30% of new buildings by 2025; The emission of construction waste at the new construction site shall be controlled below 300 tons per 10000 square meters.

From the perspective of regional market, in recent years, a large number of precast component factories have been built in the Yangtze River Delta, such as Jiangsu, Anhui and Zhejiang, which is also the premise for the rapid development of precast construction industry in Jiangsu, Zhejiang and Huizhou.

It is urgent to accelerate the implementation of energy conservation and emission reduction in the industry.

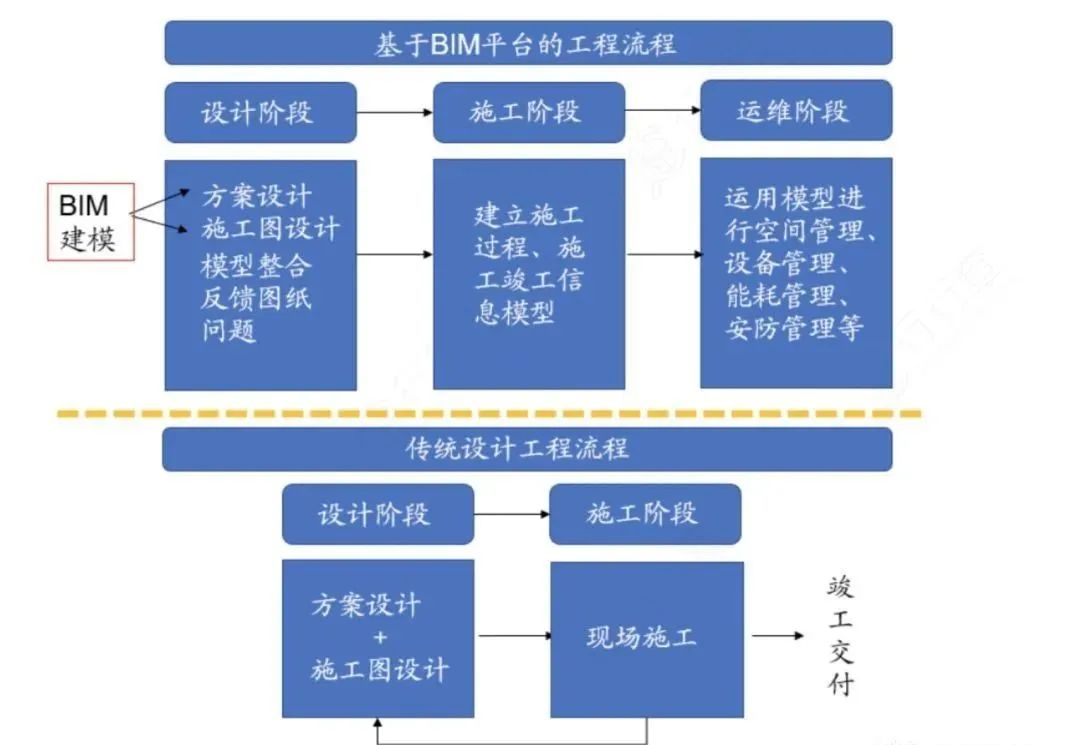

The process of precast building industry chain is long, and the additional cost brought by design change is large, so the requirements for the accuracy of component deepening design and the matching degree with production are higher; The information system based on BIM Technology helps to improve the design accuracy, reduce the project cost and shorten the project duration.

Precast building design is usually divided into early stage technical planning, scheme design, overall design, construction drawing design and component design (component splitting, component detail drawing and component node optimization).

The industrial chain of precast construction industry can be divided into three parts.

Its emission reduction is of great significance to the overall goal of double carbon.

Midstream: the production link of precast components.

The design enterprise carries out personalized design for the project according to the requirements of the developer, issues the drawings to the manufacturer, prefabricates the building structural parts, and then transports them to the construction site to complete the subsequent construction and decoration, and finally the sales unit completes the sale.

According to the prediction of China Building Energy Conservation Association, according to the current situation, the peak time of carbon emission in China’s construction industry is expected to be around 2039, nine years later than the whole country.

The fixed cost of precast components accounts for a large proportion in the cost of precast construction.

The two major characteristics of precast building construction are complex structural design and many precast components.

According to the plan, a high-quality development system framework for the construction industry will be initially formed by 2025.

Among them, the production and use of concrete precast units (PC components) are the core.

A market mechanism for the treatment and reuse of construction waste has been preliminarily formed, and a number of green construction demonstration projects have been built.

Under the guidance of the government’s precast building development plan and incentive policies, as the development focus of building industrialization, precast buildings are expected to usher in explosive growth opportunities..

The proportion of carbon emissions from construction related industries is as high as 51%, which is much higher than that of other industries.

As the enterprises with the development of the whole industrial chain have more or less management limits, cash flow pressure and investment capital restrictions, at the same time, the demand of precast buildings for on-site workers is greatly reduced, only simple assembly on site is required, and the core value of the industrial chain is integrated into the end of the factory.

At present, the pattern of PC component industry is scattered, and Cr5 is 44.7%.

The construction mode of precast buildings is design factory manufacturing on-site installation.

Frost & Sullivan predicts that the compound market growth rate of PC components will remain at 65% from 2020 to 2023.

The construction of precast buildings is the most important way to realize green environmental protection in the construction field.

Compared with the traditional design on-site construction, it is possible to find that the components manufactured in the factory can not be used until the installation stage due to the unreasonable design drawings, resulting in a waste of resources.

With the gradual growth of industrial development and the increase of the quantities of precast buildings, the amortization cost of land, plant, equipment and formwork of PC component factory will have a large room for decline.

Because the industrialized production of precast buildings greatly reduces the pollution caused by on-site construction and improves the environmental friendliness of construction, it has become the main direction of the reform of the construction industry.