Precast decoration | precast interior decoration and decoration works under the background of industry 4.0

This article comes from the observation of assembly Yilang digital industrial assembly decoration industry.

In addition, due to the technical convenience brought by digitization, the collaboration speed and efficiency in all aspects have been greatly improved.

Local governments have actively responded to the call.

The intervention of assembly will make the home decoration industry form a pattern of medium and low-end decoration industrialization, fine and manual high-end market.

Continuous on-line assembly enables construction industrialization.

With the introduction of assembly schemes in various provinces and cities, the policy preference has attracted the great attention of many real estate and decoration enterprises, and they have put all their efforts into promoting the development of “assembly”.

If you add building materials, some experts calculate that it is about 40%.

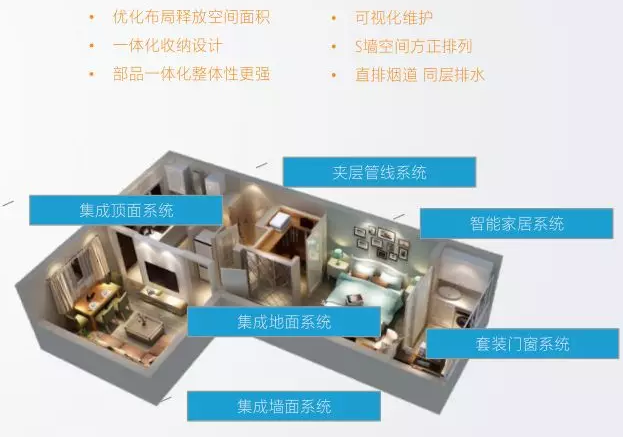

Precast decoration is mainly for interior decoration to build industrialized industrial housing.

It is understood that precast buildings can reduce at least more than 50% of the on-site construction time, and the erection site is basically free of dust and construction waste, minimizing the environmental problems caused by traditional construction methods.

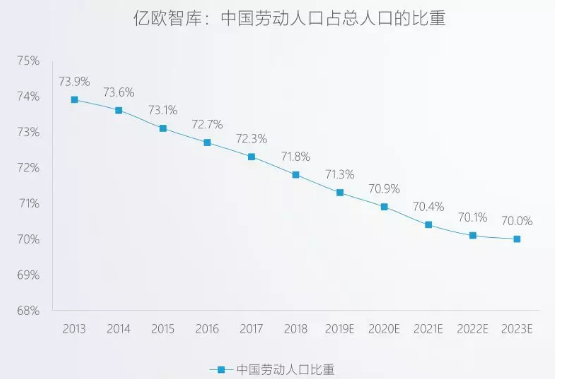

From 2013 to 2018, the proportion of China’s working population fell from 73.9% to 71.8%.

If the decoration industry continues to use the traditional construction methods, there may be labor pressure.

At present, the advantages of precast decoration in standardized and large-scale decoration projects are extremely prominent, such as affordable housing, long rent apartments, hotels, hospitals, etc., which can maximize the advantages of precast decoration, greatly shorten the working period, and enable customers to enter the operation state quickly and reduce costs.

Facing the huge market demand, industrialization has become a way to maximize the decoration efficiency and reduce the cost.

Compared with finished furniture, customized furniture has the advantages of high space utilization, unified style of the whole house and advanced landing service, which has set off the trend of reform in the furniture industry.

Each company has different understanding and implementation methods.

In recent years, precast buildings have attracted great attention from all walks of life.

In other words, about 1 / 3 of China’s energy is consumed in the construction industry.

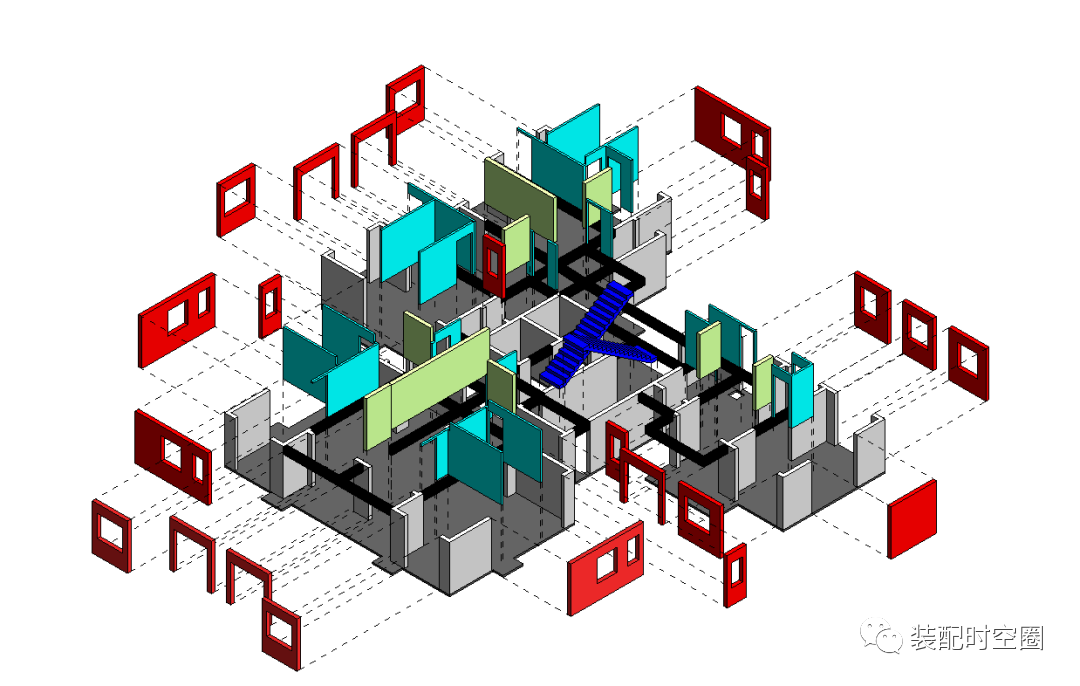

The precast technology mainly includes concrete building system, steel structure building system, interior decoration system, external enclosure technology system, equipment and pipeline and other product technology systems..

The future development demands of the construction industry will mainly focus on the realization of industrialization.

Customized furniture is personalized furniture tailored for consumers with the help of modern information technology and flexible production technology.

China Construction standards design and Research Institute said that the direct energy consumption of buildings has increased from 10% in the late 1970s to 30% in recent years.

Whether it has experienced package or Internet Storm, non-standard operation has always been a major pain point in the industry.

After the 1990s: finished furniture became popular, large-scale production, multi production base layout, improved manufacturing efficiency, expanded transportation radius, enhanced brand, and large enterprises appeared, but the personalized design was weak and the level of intelligence was low.

Home decoration is a typical labor-intensive industry.

The decoration method provided by assembly is the transformation from on-site service of craftsmen to industrialized production.

Assembly technology can be said to be a process or an idea of industrial construction.

At present, the vast majority of domestic buildings still use the traditional cement mortar construction method, which not only has a long construction period, consumes a lot of manpower, but also has serious environmental pollution.

Under the call of the national top decision-making level to “develop precast buildings and promote the industrialization of new buildings”, local governments have also responded to the call and actively planned relevant policies for precast interior decoration.

After 2000: customized furniture began to prevail gradually.

The pollution problem of the traditional construction industry is serious, and it is imperative to complete the construction industrialization.

However, looking at the development of the industry, it is still in a development stage of subcontracting at all levels, poor management level and low efficiency.

In the context of industry 4.0, the industrialization path of the large residential industry should take the assembly type as the main path, extending upward to architectural design and construction, downward to include home decoration and local renovation.

Precast buildings have risen to the national policy level.

Whether at the national, market, industry or user level, there are higher requirements and standards for construction industrialization.

In addition to the consumption of building materials, there are also varying degrees of pollution.

Let’s review the development path of China’s customized furniture industry: before the 1990s: China’s furniture was mainly made by hand, one-to-one production, there was no large-scale mechanized equipment, the production cycle was long, the sales radius was short, the work efficiency was low, and the manufacturers were mainly regional small enterprises.

Keynes theory pointed out that wages have downward rigidity, the transfer of rural labor force to cities has slowed down significantly, and the annual net increase of migrant workers has decreased from 12.45 million in 2010 to 1.84 million in 2018.

During the two sessions in 2019, the changes in the number of labor force population deserve the attention of the whole industry: from the supply side, the population of working age continues to decrease, with a cumulative decrease of about 28 million since 2012.

The home decoration industry has developed for nearly 30 years.

The assembly type, a seemingly unfamiliar word, will be related to everyone’s daily life in the future.

Different companies will build their own assembled products from different angles, different customer positioning and different structural analysis.

Within ten years, the average wage of urban unit employment increased by 2.57 times, and the compound annual growth rate reached 10%.

The construction industry brings 60 trillion output value to the world and 20 trillion growth to China’s GDP every year.

With fewer and fewer traditional craft employees and less and less non renewable material resources, it is urgent for the construction industry to change the decoration mode of the inherent mode.

One way to realize industrialization is to develop precast technology.

The change in the number of labor force population is also a reminder that the labor dividend is fading.

In the traditional wet decoration, each decoration site is a small production workshop, and the quality of products depends on the skills of constructors in each process, such as water, electricity, wood, tile and oil.

Compared with hand-made furniture, customized furniture has stable quality and strong environmental protection.