(precast Engineering) position deviation of embedded parts of precast components

3.1.4 during concrete pouring, the vibrating rod shall not directly touch the formwork, embedded parts and fixed reinforcement of embedded parts.

2.3 during the production process of components, the production personnel and special inspectors did not check against the design drawings, resulting in incorrect use of embedded parts, missing quantity, out of tolerance of buried height or out of tolerance of centerline position offset.

Before concrete pouring, the quality inspector should carefully check the specification, quantity, position, elevation, surface flatness and installation quality of embedded parts.

Pouring can be carried out only after passing the acceptance.

2.5 during concrete pouring, the embedded parts are displaced after being impacted by the vibrator.

4.3 concrete vibration…

After the completion of concrete pouring, the position of each embedded part should be carefully checked.

04 key points of quality control 4.1 specification and size of embedded parts.

3.2.3 after the completion of concrete pouring, the position of each embedded part shall be carefully checked, and the deviation shall be corrected in time after it is found.

If the position error exceeds the requirements and the quantity does not meet the requirements of the drawing, it must be made again.

02 cause analysis 2.1 purchased embedded parts or self-made embedded parts are directly used without acceptance.

3.1.3 strengthen the process inspection and earnestly implement the inspection system.

03 prevention measures 3.1 construction measures 3.1.1 process the embedded parts in strict accordance with the specifications and dimensions required by the design to ensure that the specifications and dimensions of the embedded parts are correct.

3.2 management measures 3.2.1 the special inspection personnel can only use the purchased or self-made embedded parts after their materials, specifications and dimensions are accepted.

2.2 the positioning holes of embedded parts are omitted during mold manufacturing, the positioning tools are deformed after repeated use, and the positioning holes are inaccurate.

If any displacement is found, the embedded parts should be fixed again before the concrete sets (as shown in figure 3.1.4).

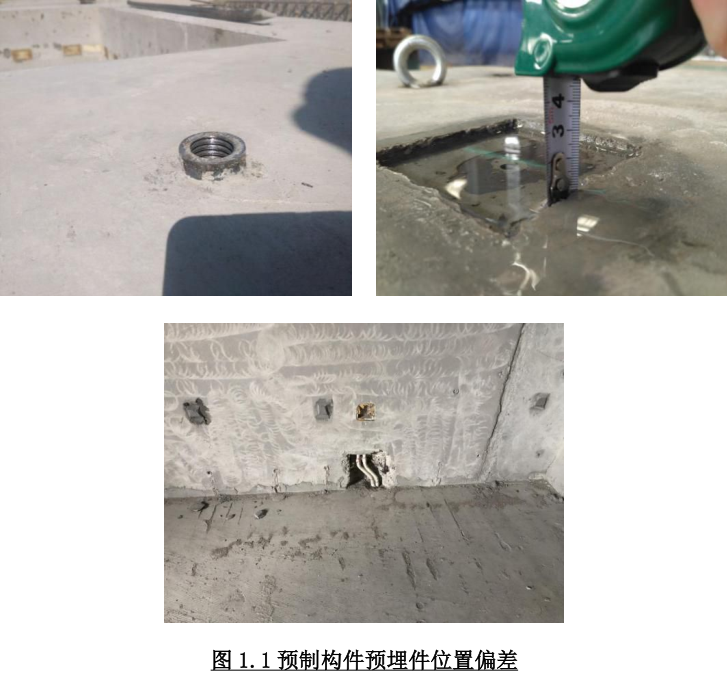

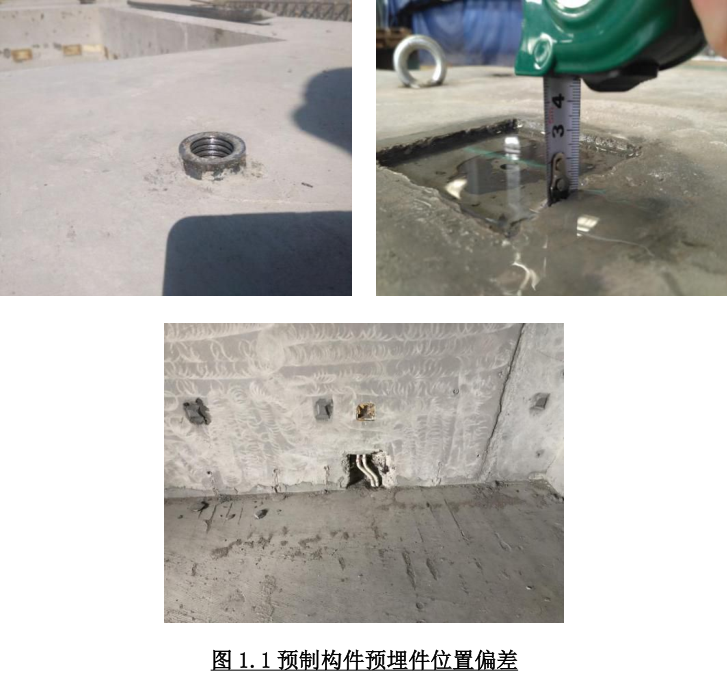

Content source: Guide to prevention and control measures for common problems of engineering entity quality in Hebei Province (2021 Edition) 01 phenomenon description: the position of embedded parts such as center line box, line pipe, lifting point and embedded iron parts of components is offset and twisted, the upper surface is uneven, the protruding concrete surface or the subsidence depth is out of tolerance (as shown in Figure 1.1).

3.1.2 when embedded parts are buried, they should be firmly fixed, and the embedded box should be blocked.

2.4 the operator did not fix the embedded parts firmly.

4.2 positioning and fixing of embedded parts.

2.6 when plastering, the displaced embedded parts are not carefully corrected back to the correct position.

3.2.2 strengthen technical disclosure, do a good job in concealed acceptance before concrete pouring, and the installation and positioning accuracy and fixation firmness of embedded parts should meet the requirements of technical specifications.