Research on the construction of “the first mock examination to the bottom” assembled fever clinic

The cast fever clinic has high requirements on the construction technology and construction progress, so it is necessary to quickly and accurately locate the components and complete the installation with high quality.

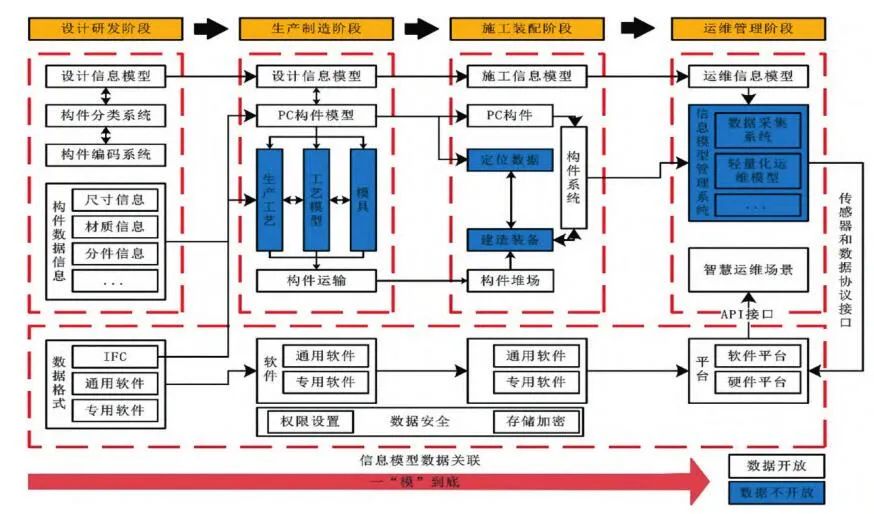

The “the first mock examination to the end” of precast buildings refers to the application of BIM (Building Information Modeling) technology to the design of the project, the manufacturing, transportation, installation, facility operation and maintenance and other subsequent processes of precast components.

58), the fever clinics can be divided into modules, and standardized module design can be carried out for some spaces to form a modular medical space (Table 1).

In combination with the relevant requirements of the Management Specifications for the Setting of Fever Outpatients (Joint Prevention and Control Mechanism YJF [2021] No.

The construction process of precast buildings is to produce precast components such as walls required by the building in the factory workshop according to the design requirements, and then transport the precast components to the construction site and install them through mechanical splicing.

For example, Wuhan Huoshenshan Hospital was completed and put into use in only 10 days.

Building a clear and clear component system is the basis for the design of precast buildings.

After the “SARS” incident in 2003, fever clinics came into being to reduce cross infection within medical institutions.

By dividing the assembly module, the fever clinic can be divided into several modules such as office, consulting room and toilet for design.

It can give full play to the advantages of BIM technology in data integration and information collaboration, integrate the whole industrial chain of precast buildings, and achieve the full process and all-round information integration and application of precast buildings from design, production, construction to operation and maintenance, so as to improve the construction quality, construction and operation and maintenance efficiency of precast buildings.

Each stage of the whole life cycle of precast buildings revolves around building components.

At present, the common problems in BIM application of precast buildings are: the design principle of precast buildings is not considered at the beginning of the design, and the components are disassembled later; Repeated modeling cannot achieve “the first mock examination to the end”.

Since the outbreak of COVID-19, in order to effectively respond to the normalization of epidemic prevention and control, the construction of fever clinics has attracted much attention.

1、 Assembled design components are the basic elements of a building.

A single room that cannot form an assembled module can be disassembled into multiple sub units for subsequent construction in the form of components.

The solution to these problems is to guide the industry to carry out BIM positive design, and strive to make BIM technology run through the whole process of “design production construction operation and maintenance”.

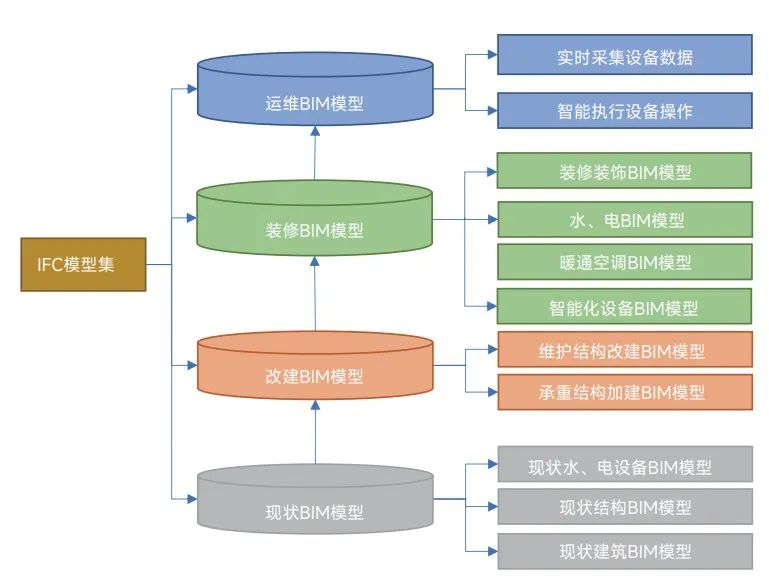

It has five characteristics: multiple software read-write, self file clear code readability, clear structure, professional base class and customizable..

80) and the Construction Standards for Fever Outpatients in Medical Institutions of Jiangsu Province (2021 Edition) (SFJY [2021] No.

The idea of component classification and segmentation based on “component method” is the core idea of building project information management using BIM technology.

Figure 1 Model architecture based on IFC IFC is a file format used to exchange and share between different construction entities.

2、 The biggest difference between the precast building construction project and the traditional construction project is the construction automation and mechanization.

It is of great significance for BIM system’s building component information collection and input, material and engineering quantity statistics, building construction, operation and maintenance, and information management of the whole life cycle.

After the completion of production in the factory, the modules are transported to the site for assembly.

While improving the quality and safety factor of precast buildings, the waste of materials and energy is reduced, and the construction period is greatly shortened.

The isolation ward of the Third People’s Hospital in Jiangdu District, Yangzhou City and the emergency project of Nanjing Public Health Medical Center have effectively improved the construction efficiency by using assembly technology.

At the beginning of the COVID-19, precast buildings played an important role.

Using this idea to number and classify components is the basis for BIM technology to be applied to the whole life cycle management of building construction projects.

“The first mock examination to the end” is mainly realized through six “model” technologies, including: “model” foundation – architecture of full life cycle building information data system based on IFC (Industry Foundation Classes) data format; “Model” simulation – information architecture table, performance simulation and auxiliary design at the design stage; “Model” transfer – transportation planning and yard management in the transfer stage; “Mold” assembly – intelligent engineering management and carbon emission monitoring in the assembly stage; “Model” operation and maintenance – intelligent operation and maintenance management software module development in the operation and maintenance stage; “Model” statistics – material statistics in the reuse stage.

It has the characteristics of short construction time, effective saving of manpower and material resources.

Effective integration of BIM technology and precast buildings can achieve lean construction of fever clinics.

In BIM forward design, it is necessary to use theory and method to guide the design of precast buildings, and to formulate a series of rules to standardize BIM modeling and collaborative work.

The precast building has the characteristics of standardized component design, refined factory production and lean engineering management.

Fever clinics can intervene patients with potential infectious diseases in advance, which can effectively prevent and control cross infection in hospitals.

Precast buildings are assembled by building components with various functions, scales and levels.

As early as the 19th century, the “mobile hospital” was the embryonic form of the assembly hospital.

The establishment of theories, methods and rules is the guarantee for the successful application of BIM positive design in the construction of precast buildings.

Practice has proved that it is of great significance to improve the construction efficiency of fever clinics based on the concept of “combination of epidemic prevention and control”, combined with BIM and assembly construction technology, for timely response to epidemic prevention and control in emergency situations.