Selection of precast concrete structural system and key points of structural design

2.

When the vertical reinforcement of the upper and lower precast shear walls is connected by sleeve grouting, and the vertical distributed reinforcement is connected by the “plum shaped” part, the reinforcement ratio of the connecting reinforcement shall not be less than the minimum reinforcement ratio of the vertical distributed steel reinforcement of the shear wall specified in the current national standard code for seismic design of buildings GB50011, the diameter of the connecting reinforcement shall not be less than 12mm, and the spacing on the same side shall not be greater than 600mm, The unconnected distributed reinforcement is not included in the bearing capacity design of shear wall members and the calculation of distributed reinforcement ratio.

The prefabrication difficulty is low, the cost is low, the mechanical performance is good, the construction difficulty is great, and the wall slab is thick, Structural self-supporting double-sided laminated plate shear wall structure double-sided laminated shear wall, laminated beam, laminated floor, precast balcony and precast staircase walls are connected by additional reinforcement vertically, and the horizontal additional reinforcement connection is simple and integral, and the cost is reduced, and the wall is slightly thicker At present, there is not much engineering experience that can be used for reference in China.

The common precast residential system in China is analyzed.

Control the seismic overturning moment borne by the precast shear wall to be less than 50% of the total overturning moment at the bottom of the structure.

7.

In the high-rise assembled integral concrete structure, the floor shall meet the following requirements: 1) The cast-in-situ floor should be used for the structural transfer floor and the floor as the embedded part of the superstructure; 2) The cast-in-place floor should be used for the roof layer and the floor with complex plane stress.

Indoor beam exposure affects comfort, high cost, and the number of structural floors and total height are limited.

The comparison of various systems is shown in the following table: the connection characteristics of precast components of the system, advantages and disadvantages, precast integral frame structure, precast frame columns, composite beams, composite floors, precast balconies, and precast stair columns are connected by grouting sleeves The beam column cast-in-place joint connection is located in the node area or the middle of the beam span area, with mature technology, good internal space freedom and high degree of industrialization.

The diameter of the reinforcement should not be less than 8mm, and the spacing should not be greater than 200mm.

Structural design requirements 1.

5.

The horizontal reinforcement connection of the precast shear wall adopts the lap anchorage in the cast-in-place section, and the edge component position adopts the cast-in-place method.

When the composite floor is used, the thickness of the post cast concrete composite layer of the floor should not be less than 100mm, and the two-way full-length reinforcement should be used in the post cast layer.

4.

For the assembled integral shear wall structure with both cast-in-place and precast wall limbs in the same floor, the horizontal seismic bending moment and shear force of cast-in-place wall limbs should be multiplied by an increase factor of not less than 1.1.

Articles and pictures are only for learning, such as copyright issues or disagreements.

3.

Indoor exposed beams and columns affect the comfort of residential use.

Rough surfaces or keyways are reserved on the top, bottom and sides of the precast shear wall to connect with the cast-in-place concrete to strengthen the structural integrity.

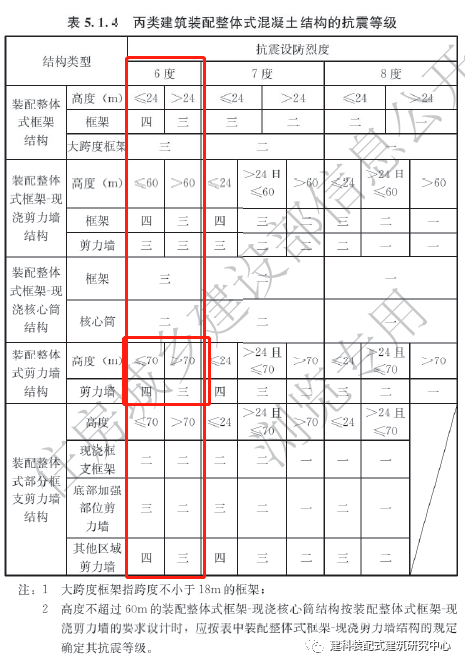

The assembled integral concrete structure of high-rise buildings should meet the following requirements: 1) when setting basements, cast-in-place concrete should be used; 2) The reinforced part at the bottom of shear wall structure and some frame supported shear wall structures should be cast-in-place concrete; 3) The first floor column of frame structure should be cast-in-place concrete; 4) When the shear wall at the bottom strengthening part and the first floor column of the frame structure adopt precast concrete, reliable technical measures should be taken.

5.

The shear wall adopts cast-in-place construction, which is relatively simple and has good integrity.

Precast shear walls, composite beams, precast balconies The precast stair wall is vertically connected by grouting sleeve or grout anchor, and the horizontal additional reinforcement is connected.

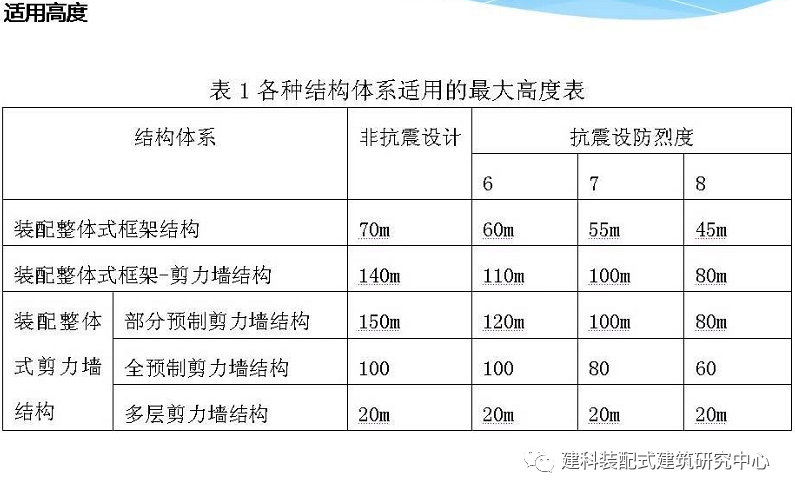

According to the structural system, it can be divided into precast frame structure, precast frame shear wall structure, and precast shear wall structure.

Precast frame columns, composite beams, composite floors, precast balconies, and precast stair columns of precast frame cast-in-place shear wall structures are connected by grouting sleeves, and beams and columns are connected by cast-in-place joints.

Precast shear wall structures are assembled with integral shear wall structures.

The node connection construction is difficult.

According to the requirements of the design code: under the specified horizontal force, when the total shear force borne by the bottom of the precast shear wall component is greater than 50% of the total shear force of the floor, the maximum applicable height of the precast integral shear wall structure is appropriately reduced; When the total shear force borne by the bottom of the precast shear wall structure is greater than 80% of the total shear force of the floor, the maximum applicable height will be reduced by 10m from the original foundation.

6.

It is rarely used in residential buildings in China.

The precast composite shear wall (PCF) is a single-sided composite shear wall, precast balcony, precast stair PCF and the cast-in-place wall form an integral external wall.

When the precast shear wall is connected by sleeve grouting, the horizontally distributed reinforcement of the precast shear wall needs to be densified within 300nm from the bottom of the sleeve to the top of the sleeve.

There are no beams and columns protruding in the room, the degree of industrialization is high, and the construction requirements are high.