Spoiler before assembly project (colored egg at the end of the article)

Take another look at the following paragraph of the 14th five year plan.

The overall index of cast-in-situ control is also controlled by assembly type.

In my spare time, I can’t help but make complaints about it (after all, the formal curriculum is not suitable for everyone’s precious time).

Develop and use parametric and generative design software to explore the application of artificial intelligence technology in design.

In February 2017, the implementation opinions of the general office of Beijing Municipal People’s Government on accelerating the development of precast buildings were released, and the development of precast buildings in Beijing has entered a comprehensive promotion stage.

This standard is prepared in accordance with the principles of standardized design, factory production, assembly construction, integrated decoration, information management and intelligent application, the basic requirements of systematic integrated assembly, the compilation principles and evaluation methods of the national standard evaluation standard for precast buildings GB / t51129, and in combination with the development of precast buildings in Beijing.

The first time I came into contact with the assembled structure was about 2015.

Beijing, Shanghai, Guangzhou and Shenzhen (no discrimination against other places) generally have a very good understanding of the government’s intention.

The second topic is whether the safety of concrete assembly is guaranteed? Honestly, I don’t know..

Improve the requirements for the preparation depth of construction drawing design documents, improve the fine design level, and provide the basis for subsequent fine production and construction.

Build a standardized design and production system for precast buildings, promote the intelligent upgrading of production and construction, expand the use scale of standardized components and parts, and improve the comprehensive benefits of precast buildings.

The reason is very simple.

Therefore, for friends who have been doing concrete design for many years, we must despise them strategically and pay attention to them tactically.

One characteristic of concrete assembly type is that it is “equivalent to cast-in-situ”.

First of all, this problem has nothing to do with the curriculum of Luban structural Institute.

To some extent, they represent a trend of the industry.

It is not difficult to see the red font above, so we should vigorously promote the application of precast buildings.

The first is whether the concrete assembly has a future? The answer is yes.

The former tells you that his calculation is not difficult, while the latter tells you that the assembly rules are very important.

We can tell you an industry law: follow the direction of the government.

Improve the steel structure building standard system, promote the establishment of a general technical system for steel structure housing, improve the pricing basis of steel structure building projects, and guide the coordinated development of upstream and downstream industrial chains with standardization as the main line.

We should care about the trend represented by numbers.

At that time, the assembled market was the same as the Fourth Ring Road in Beijing in the 1970s, a vegetable field.

For more articles on the 14th five year plan, you can click: the way out for structural engineers.

At the domestic construction level, the ideal is very plump and the reality is very skinny.

To put it bluntly, there is nothing remarkable about large calculation.

Only in order to realize the concept of “equivalent cast-in-situ”, some strengthened calculation and construction measures have been taken.

Improve the precast concrete building structure system applicable to different building types, and increase the integrated application of high-performance concrete, high-strength reinforcement, energy dissipation, shock absorption and prestress technology.

The Beijing urban master plan (2016-2035) specifies that precast buildings will be fully adopted by 2035.

Let’s think about the assembly project market in the past few years.

In recent years, with the continuous promotion of the country, the first tier cities represented by Beijing, Shanghai, Guangzhou and Shenzhen have taken the lead, and the norms and Atlas have been gradually improved.

Seeing the red font above, it is not difficult to understand that in the next ten years in Beijing, the proportion of precast applications will be higher and higher.

However, I am still afraid of the assembly type.

In fact, from my personal point of view, I dislike the assembled structure.

Apply digital means to enrich scheme creation methods and improve the creation level of architectural design schemes.

Actively promote the application of assembly decoration in commercial housing projects, promote pipeline separation and integrated decoration technology, promote integrated modular building components, and promote the deep integration of assembly decoration and precast buildings.

Here are five topics.

Research and apply geotechnical engineering survey information mining and integration technologies and methods to promote the digitization of the survey process.

Will the requirements of Beijing, Shanghai, Guangzhou and Shenzhen landmarks be faster and higher than those in other places? Let me show you the general provisions of the evaluation standard for precast buildings (DB11 / t1831-2021) issued by Beijing in 2021.

Cultivate a number of precast construction production bases.

If you don’t play according to the rules, there are great potential safety hazards.

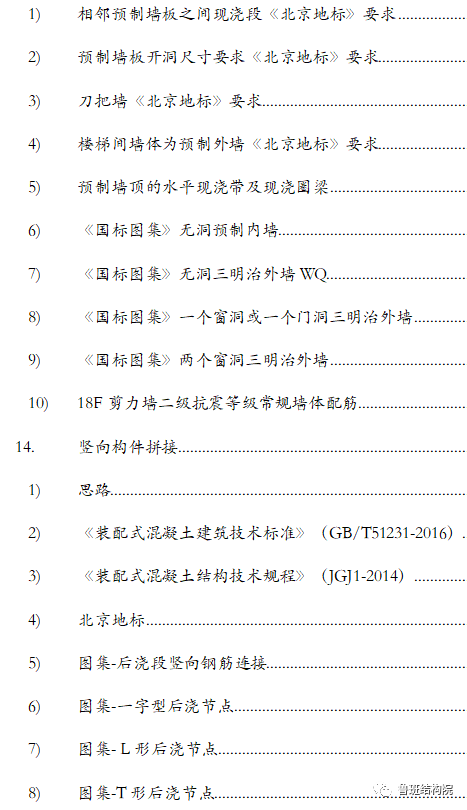

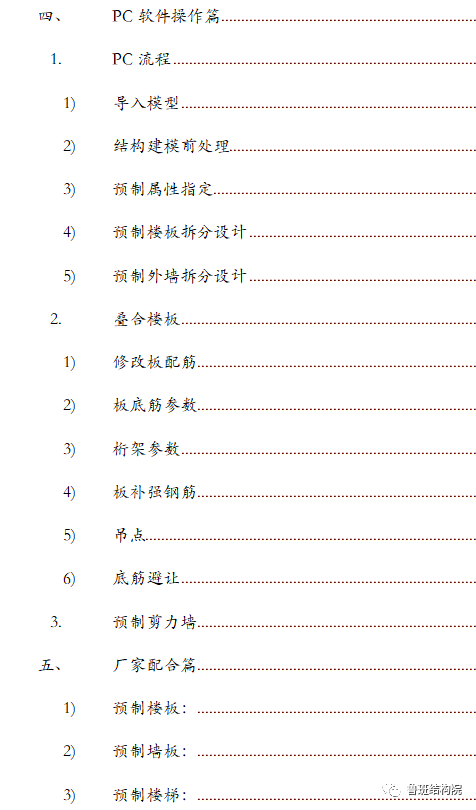

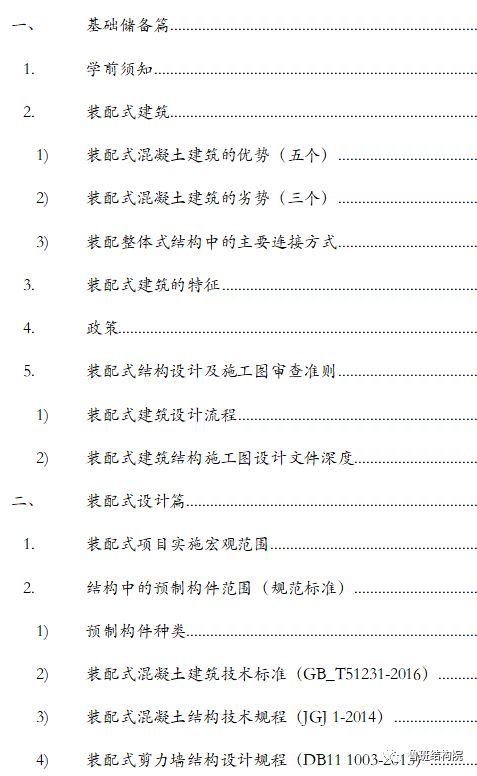

After about three months of preparation, the outline of the concrete precast topic is coming to an end.

It’s just a matter of fact.

We don’t need to care too much about numbers.

The contents are as follows: 1.0.1 the development of precast buildings is conducive to saving resources and energy, reducing construction pollution, improving labor production efficiency and quality safety level, accelerating the transformation of production mode in the construction industry, comprehensively improving construction quality, and realizing energy conservation, emission reduction and sustainable development, It is an important embodiment of implementing the development concept of innovation, coordination, green, openness and sharing in the field of housing and urban-rural construction, and promoting the innovation of construction methods in accordance with the requirements of applicability, economy, safety, green and beauty.

Encourage large-scale design enterprises to establish a digital collaborative design platform, promote the integrated design of buildings, structures, equipment pipelines and decoration, and improve the collaborative design ability of various disciplines.

Note that steel structure housing is also a trend, but at present, some hard injuries have not been solved, but it does not hinder its future.

Some friends may think 2035 is too far away.

Vigorously promote the application of precast buildings, actively promote the construction of high-quality steel structure housing, and encourage schools, hospitals and other public buildings to give priority to the use of steel structure.

In order to promote the sustainable, healthy and high-quality development of precast buildings in Beijing, reflect the specific requirements and characteristics of the development of precast buildings in Beijing, and meet the high-quality needs of building users, it is urgent to build a set of evaluation system of precast buildings suitable for the actual development of Beijing, and carry out scientific, unified and standardized evaluation.