Technical dry goods | precast building pipeline separation (SI)

The separation technology project of electrical pipeline and structural part shares the separation method of electrical pipeline and structural part of house type 01.

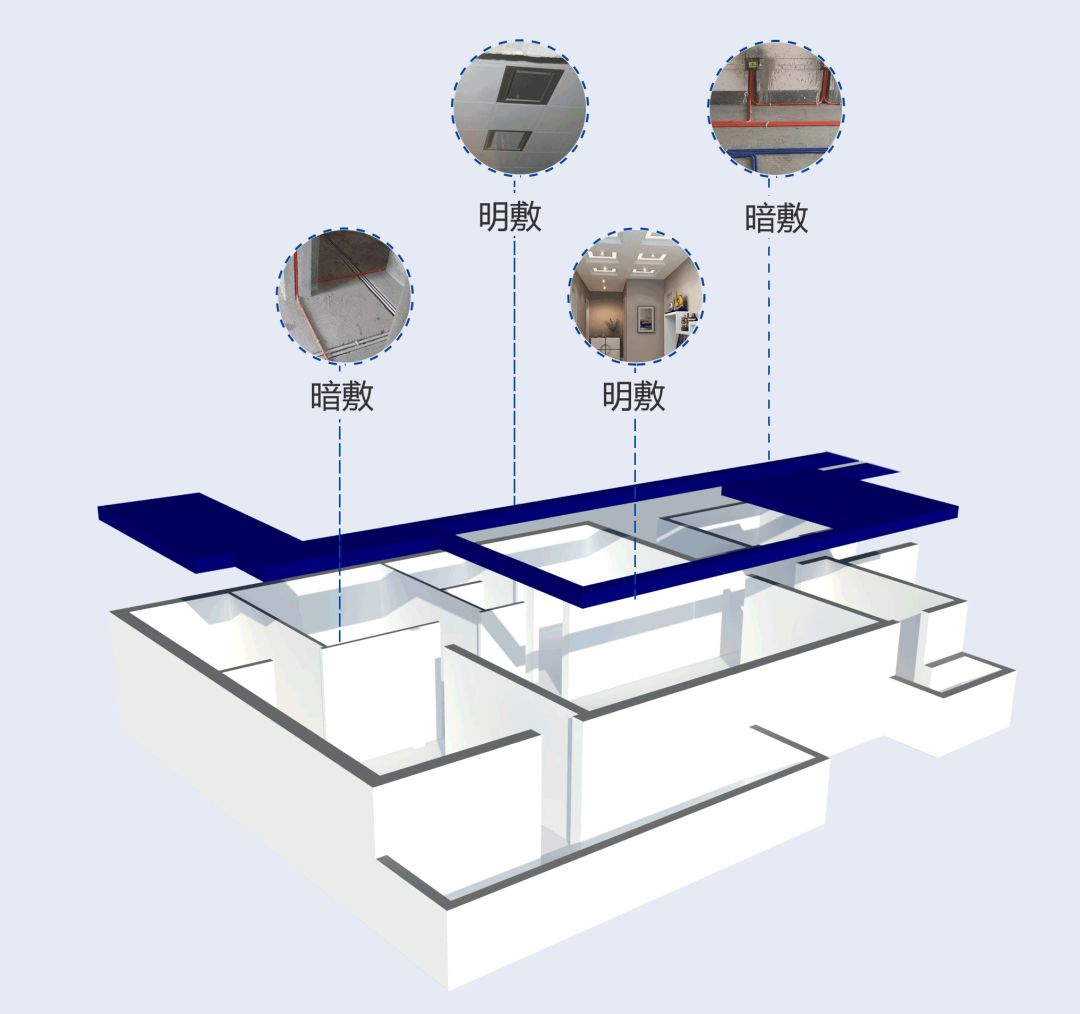

Pipeline separation: for the pipelines exposed in indoor space and laid in the ground overhead floor, non load-bearing wall cavity and ceiling (√) the pipelines are not separated: they are embedded in the structural members (excluding crossing)( ×) Pipeline not separated: the pipeline laid in the cushion of wet operation ground shall be deemed as not separated( ×) ❖ advantages and applicable suggestions: advantages: improve the convenience of daily equipment maintenance, greatly reduce the difficulty of maintenance and improve the transparency of construction; Disadvantages: it has a great impact on hardcover; Affect the indoor clear height and width; At present, there are few examples of drawing review and approval in Wuhan; At present, there are no provisions on the vertical assembly of the main pipeline in a project built by Huazhong government, and there is no specific acceptance of the precast main pipeline in the current direction.

Among them, due to the differences between conventional projects and precast buildings, how to solve the differences between electrical conduit laying and conventional? Maybe you can find the answer after reading today’s “electrical pipeline and separation application of precast residential buildings”.

The “pipeline separation” technology is adopted.

With the further development of precast buildings, people are not satisfied with the current construction methods, and hope to upgrade the overall quality of precast buildings and the scientific and technological content of the construction industry through new construction methods and breakthroughs in different professional technologies.

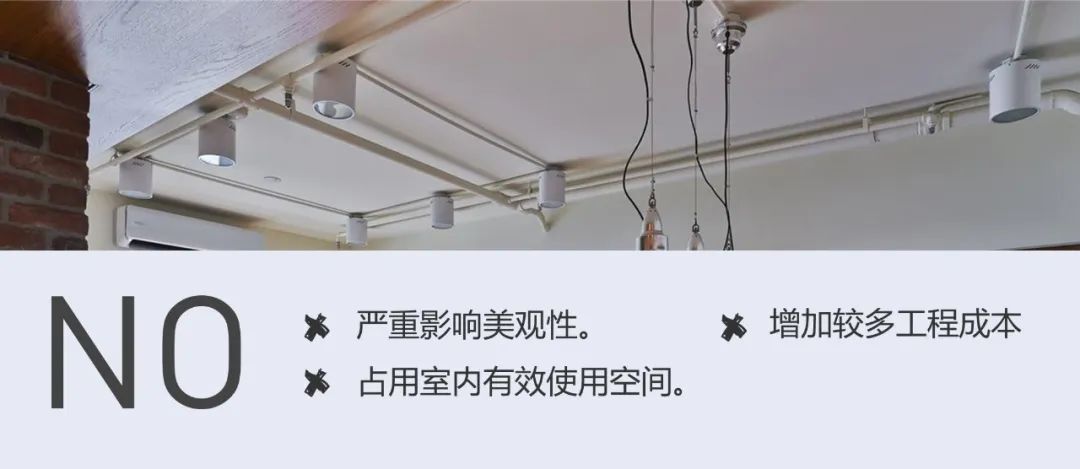

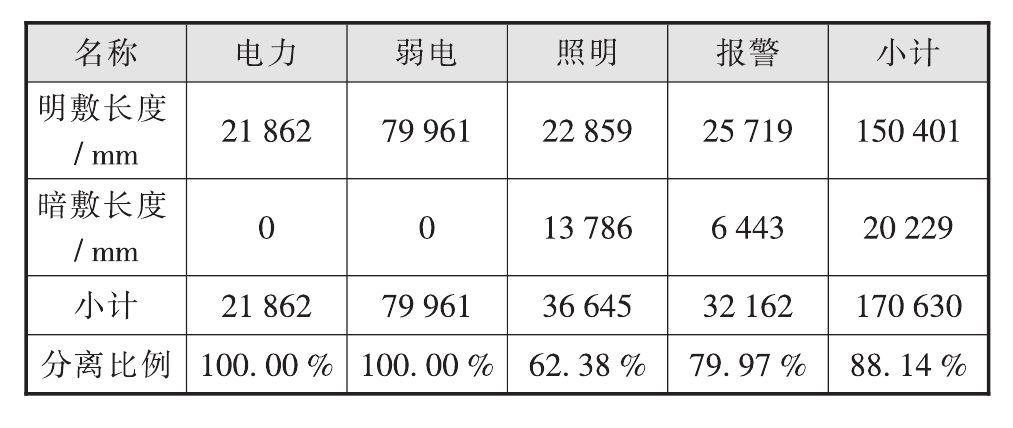

Several methods of separating electrical pipeline from structure 01 several methods of separating electrical pipeline from structure in precast residential projects, all electrical pipelines laid in the open or in the overhead floor and ceiling can be completely separated, but there are many disadvantages.

The difference between pipeline separation and traditional practice in traditional buildings, equipment pipelines for interior decoration are embedded in structural components such as concrete floors and walls or building surfaces.

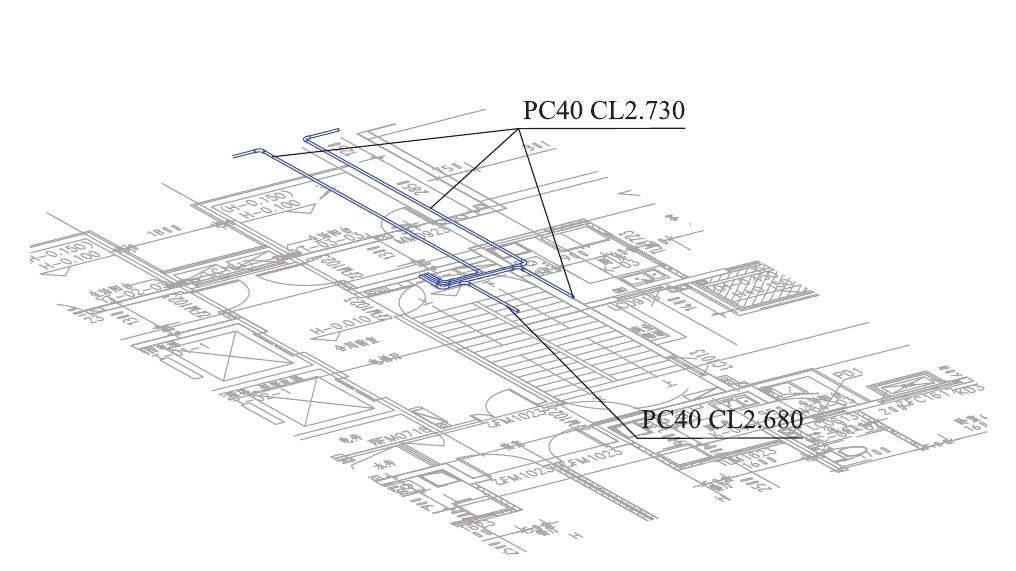

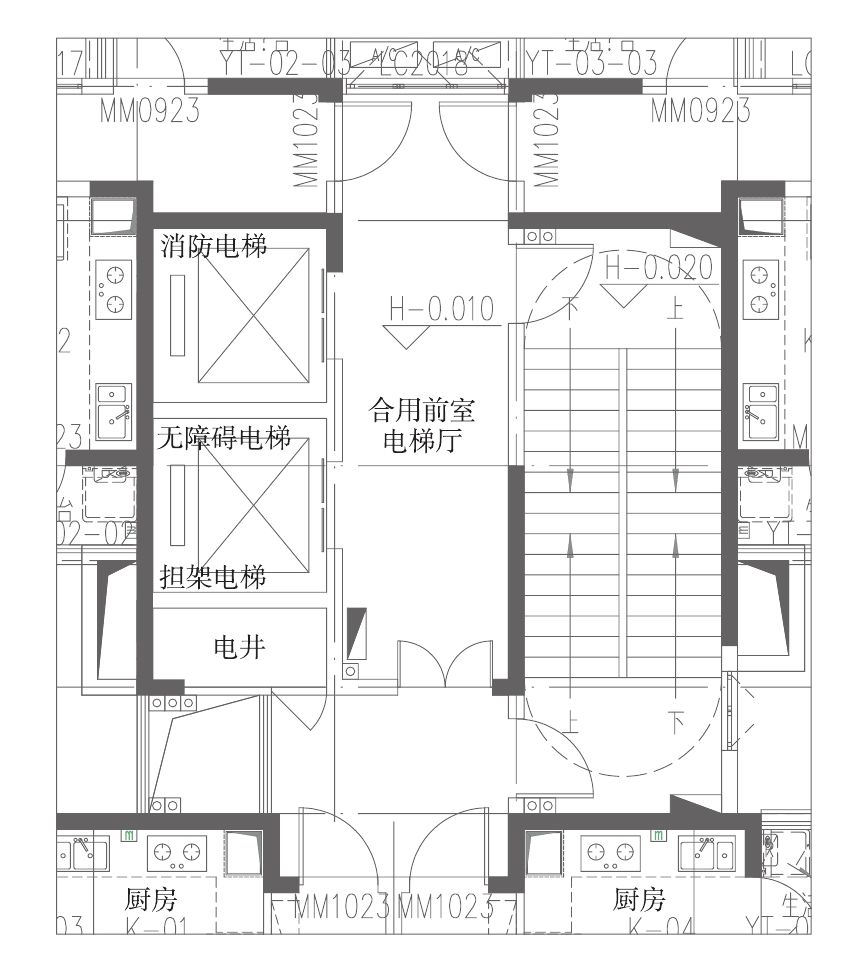

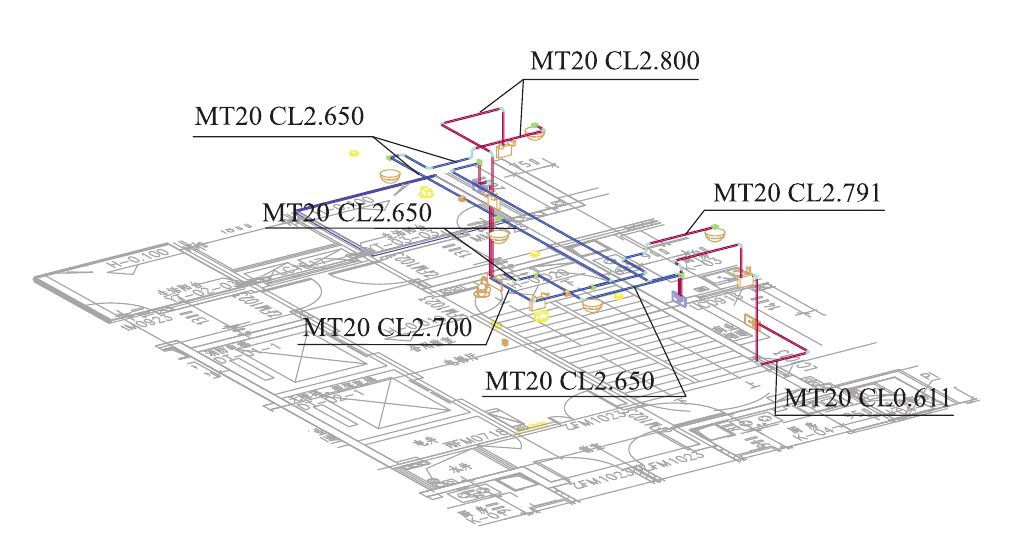

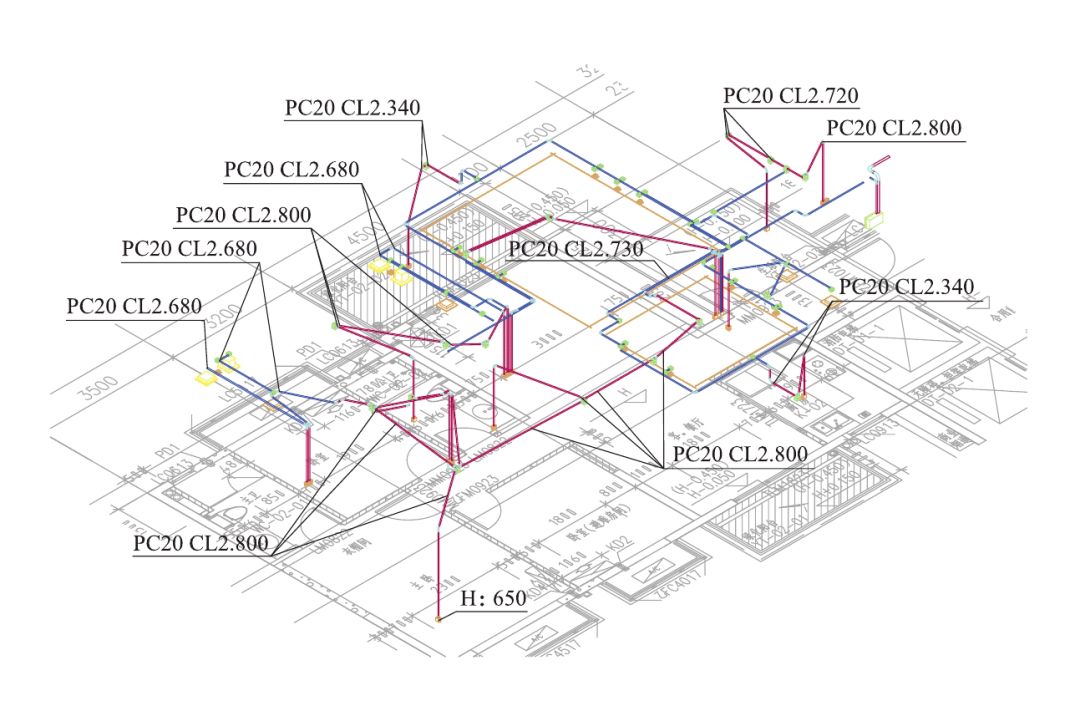

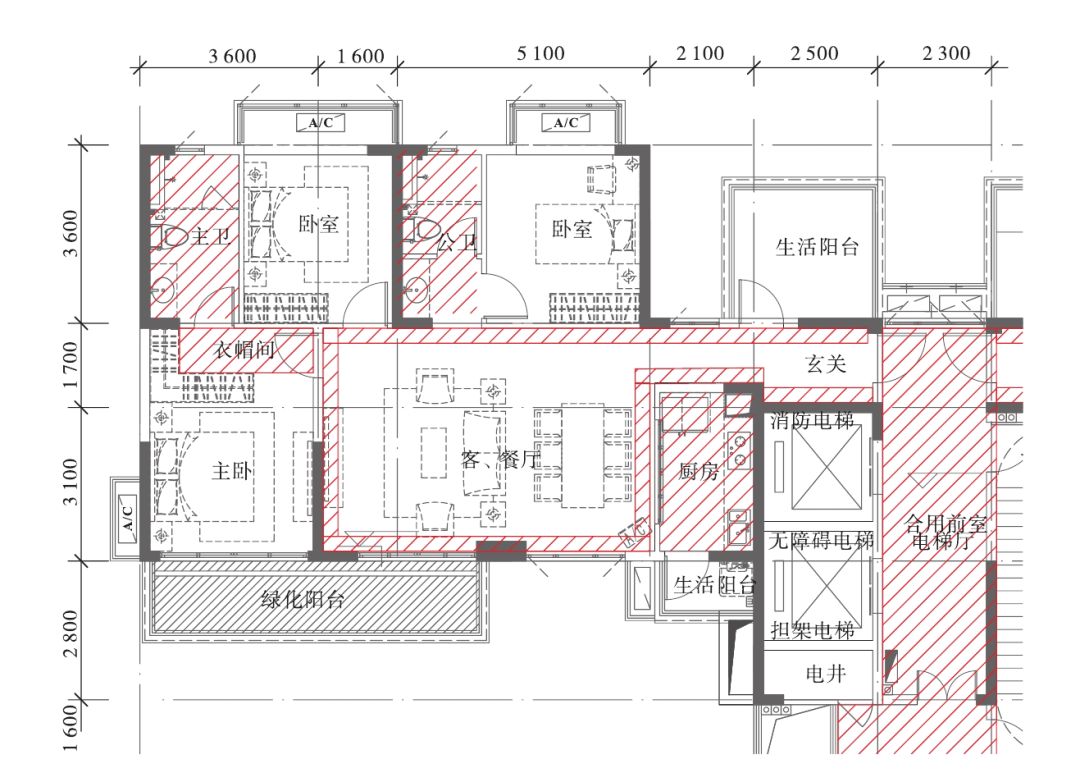

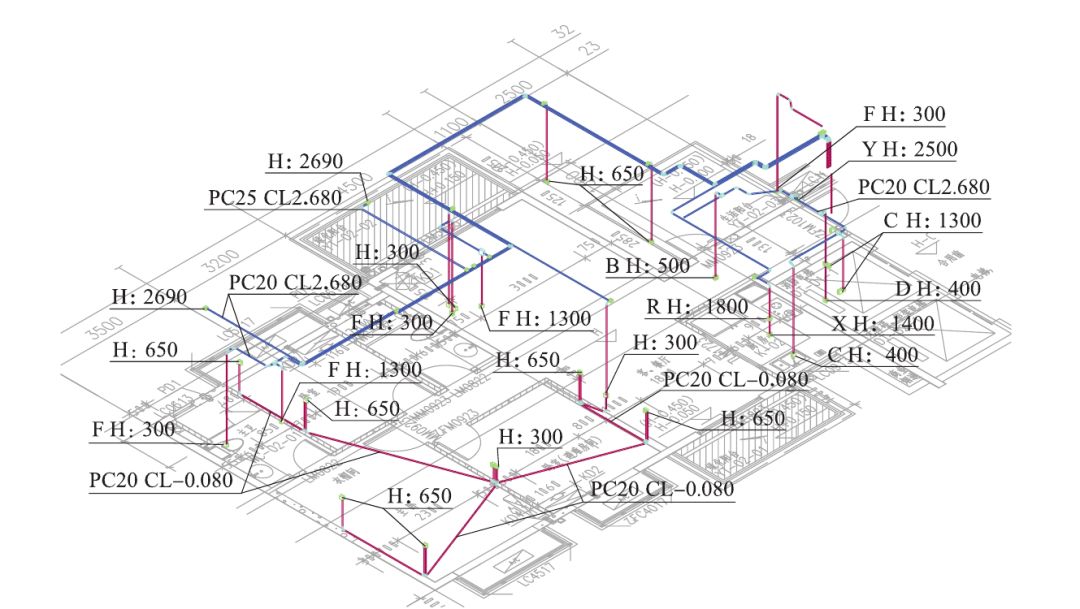

The ceiling range of residential house type fed back by interior design discipline is shown in the shadow line in Figure 1..

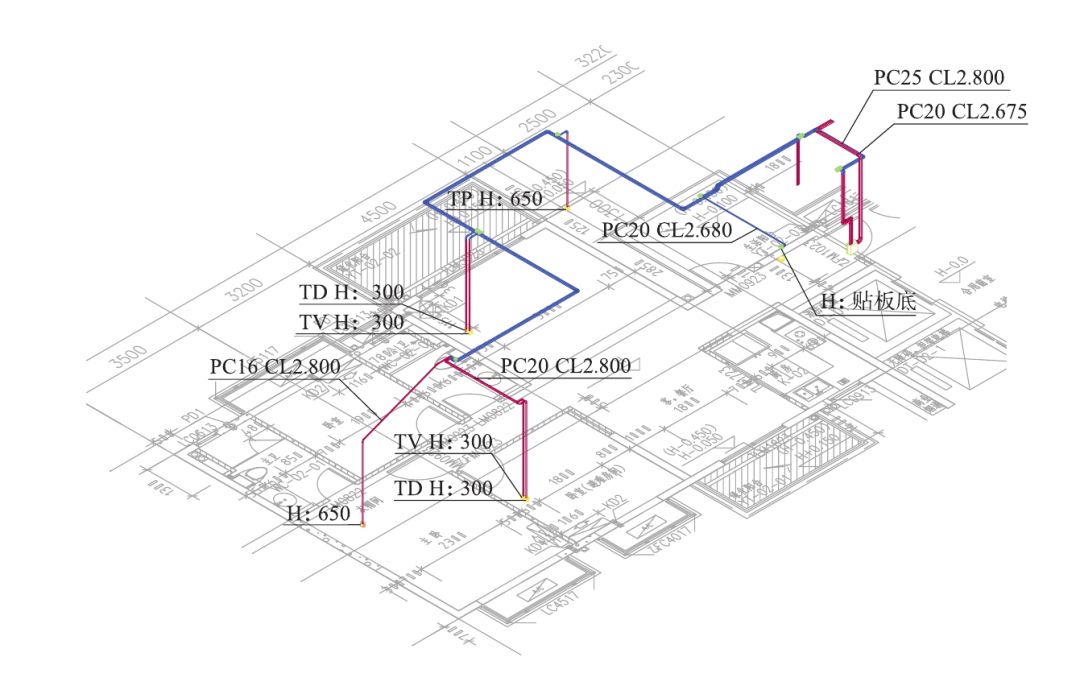

The electrical discipline includes power, lighting, weak current, alarm and other pipelines, with a pipe diameter of 20mm.

2.

The engineering overview of a project is as follows: the residential building is a cast construction project, with a total of 33 floors, and the standard floor adopts precast laminated floor slab, precast internal partition wall, precast staircase, laminated slab balcony and other precast components.

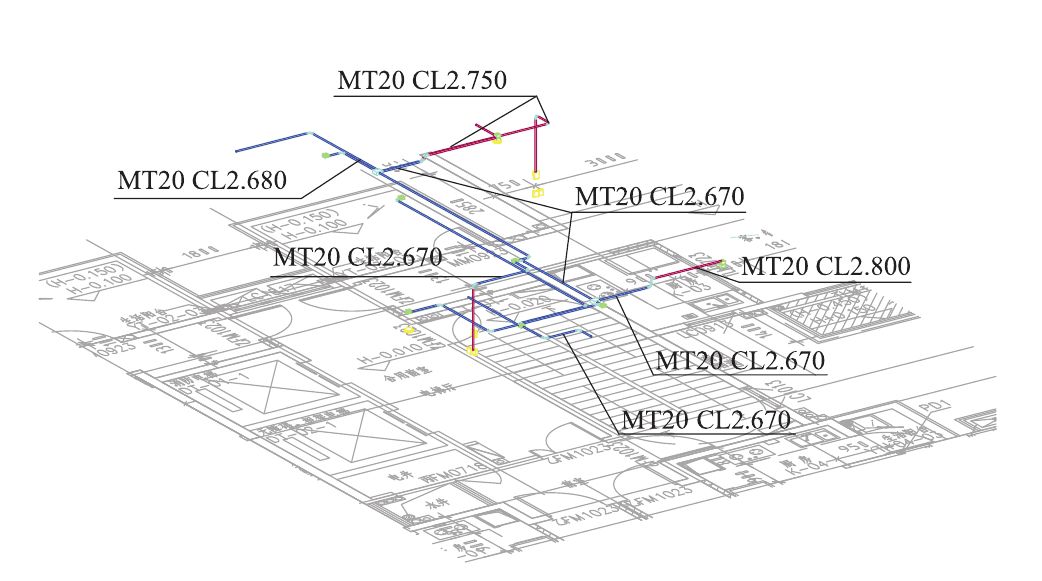

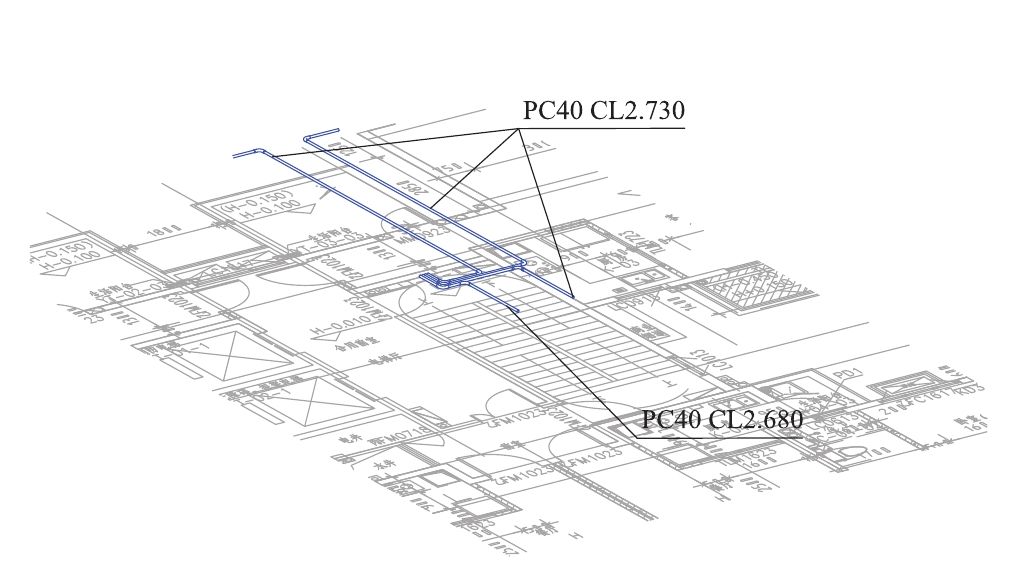

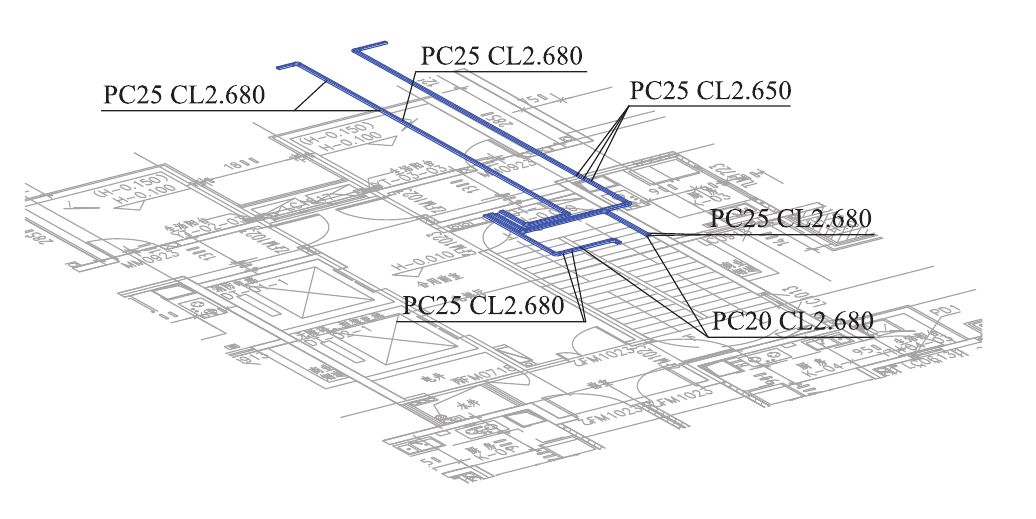

02 separation of electrical pipeline and structural part the separation technology of pipeline and structural part adopts the combination of open laying pipe and concealed laying pipe.

Conventional practice of pipeline separation technology proportion analysis of pipeline separation in precast residence ❖ basic concept: normative definition: pipeline separation is a way to set equipment and pipeline outside the structural system; Pipeline disciplines included in the calculation of pipeline separation ratio: Electrical (strong current, weak current, communication), water supply and drainage, heating and other disciplines.

It is difficult to maintain and replace the pipelines concealed in the floor.

Therefore, it is of great practical significance to scientifically separate the electrical pipeline from the structure, give full play to the advantages that the pipeline separation does not damage the protective layer of structural reinforcement, ensure the safety and stability of the structure, and avoid the post excavation phenomenon caused by the construction unit’s leakage of buried electric pipes.

At the same time, people continue to pursue the quality of life.

Electrical pipelines (including bridges) laid in the ground overhead floor and ceiling belong to the separation of pipelines and structures; Pipelines concealed in floors and walls shall be deemed as not separated.

On the premise of not affecting the safety of the main structure, it skillfully designs the laying route of electrical pipelines through the cooperation of multiple disciplines and types of work, which not only meets the aesthetics, but also facilitates people’s later renewal and maintenance.

Because it is reserved outside the main body of the building, the precast components can reduce the differences caused by embedding, improve the modularization and standardization of components, reduce the construction difficulty at the construction site, greatly increase the flexibility and reduce the high loss in the construction process.

Figure 1 plan of residential house type, which adopts the method of separating pipeline from structure.

Introduction to pipeline separation technology 1.

Pipeline separation: pipelines exposed in indoor space and laid in ground overhead floor, non load-bearing wall cavity and ceiling shall be recognized as pipeline separation; Pipeline not separated: for pipelines buried inside structural members (excluding crossing) or laid in the cushion of wet operation ground.

3.

In this way, when the equipment pipeline is aging, the concrete needs to be chiseled for transformation and renewal, and the subsequent maintenance cost is high, which also affects the service life of the building.

What is pipeline separation technology? The method of laying pipelines in the indoor heating space and the exposed ceiling and the bare water supply and drainage space is to separate the indoor water supply and drainage pipelines from the wall.

The significance of recommended pipeline separation in precast buildings in precast projects, according to the conventional practice, all electrical pipelines will be concealed at the cast-in-situ layer of the laminated floor, which will produce more intersections, which will damage the reinforcement protective layer of the structure and affect the structural safety.

When the electrical pipeline is stripped from the structural layer, the protection cost and decoration cost of the pipeline will increase accordingly.

They may decorate the interior of their living space for many times.

Applicable suggestions: complete separation is not recommended, and partial separation is recommended; The scheme of pipeline separation can be implemented: Indoor – Open laying of kitchen and bathroom, open laying of guest dining walkway in local ceiling, concealed laying of non ceiling part of laminated plate cast-in-situ layer, and concealed laying of strong and weak current box conduit led to the wall under the ceiling in precast inner wall panel; Public area – pipelines are mostly laid in the open (electric power and weak current are laid in the open, lighting and alarm are mostly laid in the open, and vertical downward to the end point is mostly laid in the dark).

The early investment cost of pipeline separation is high, but the later transformation cost is low and does no harm to the structural layer.

In order to facilitate the analysis, only one house type of the standard floor plan is selected for analysis, and the plan of the house type is shown in Figure 1.

Therefore, the method of complete separation of pipeline and structure is generally less used in precast residential projects.