Technical specification for solid strength inspection of sleeve grouting materials for reinforcement connection in precast buildings

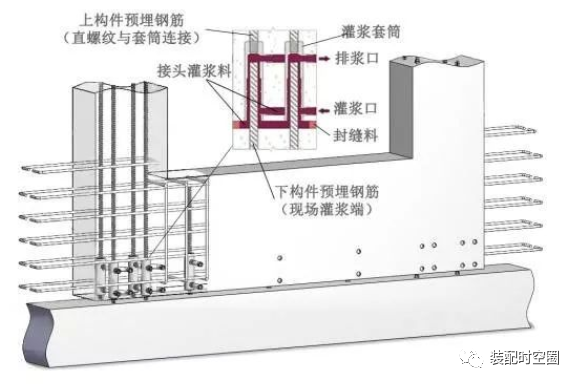

Sleeve grouting connection is one of the main ways of reinforcement connection in precast concrete structure at present.

According to the requirements of the “notice on printing and distributing the first batch of standards formulation and revision plan of Engineering Construction Association in 2017” (JB Xie Zi [2017] No.

This connection technology has the advantages of fast construction, simple stress, small additional stress, wide application range and easy to absorb construction errors.

This specification is under the centralized management of the concrete structure Professional Committee of China Engineering Construction Standardization Association and interpreted by China Academy of Building Sciences Co., Ltd.

This standard uses the idea of core drilling method to detect the concrete strength, proposes to use the small-diameter core sample method to detect the solid strength of sleeve grouting material, obtain the grouting material core sample from the grouting pipe, outlet pipe, external extension pipe and the bottom joint of vertical components, and then process it into a small-diameter cylinder core sample with a height diameter ratio of 1:1, The solid strength of the grouting material in the sleeve is evaluated by testing its compressive strength.

At present, there is no standard specification for the solid strength test of grouting material for reference.

The purpose of this specification is to standardize the testing method of solid strength of grouting material for sleeve grouting connection of precast concrete structure.

The shape and size of the small-diameter core sample are different from the standard specimen of grouting material.

As it is impossible to obtain samples meeting the test requirements inside the sleeve, according to the grouting construction process, this standard stipulates that samples shall be taken from the grouting pipe, grout outlet pipe, external extension pipe and the bottom joint of the vertical member of the connected precast concrete member on site.

Therefore, the method of using ultra-small diameter core sample to detect the compressive strength is feasible.

014) of China Engineering Construction Standardization Association, the procedure preparation team has carefully summarized practical experience after extensive investigation and research, referred to relevant international standards and foreign advanced standards, and solicited opinions, This procedure is formulated.

After the sample is processed, the compressive strength shall be tested and estimated in the laboratory.

In order to ensure the detection accuracy, specific requirements are put forward for the detection and evaluation method.

It uses the sleeve with shear groove inside and injects high-strength non shrinkage grouting material to connect the stressed reinforcement.

The parts that can be contacted or sampled are only limited to the grouting mouth and outlet.

The diameter of the sample that can be taken out is about 20mm, and the maximum particle size of the aggregate of the grouting material is less than 3mm.

Because the grouting sleeve is generally embedded in the concrete during the production of components, and the grouting material is filled in the sleeve, the detection instruments cannot directly contact the grouting material in the sleeve.

At present, there are no relevant standards to refer to for the solid strength test of grouting materials.

With the development of testing technology, considering that there may be other corresponding standards in the future, other relevant standards shall be observed when implementing this procedure…

The existing strength test method of grouting material is 40mm for trial mold making × 40mm × 160mm standard specimen.

In order to judge the conformity of the solid strength of grouting material, a large number of experimental studies have been carried out in this standard to establish the strength conversion relationship between the small-diameter core sample specimen and the standard specimen.

For other grouting processes similar to the grouting joint of reinforcement sleeve, such as grouting from grouting duct, exhaust from grouting duct and mortar anchor lap joint, the solid strength of grouting material can be tested according to this specification.

This procedure is divided into 6 chapters, mainly including: general provisions; Terms and symbols; Testing equipment: sampling rules and sampling methods; Processing of core specimen; Compressive strength test.

According to the principle of sleeve grouting connection, the quality of grouting material is an important factor affecting the connection performance of joint, and the strength of grouting material is an important index to evaluate the quality of grouting material.