The comparison between “wood” and “steel” of precast villas in Canada saves labor costs and time, and improves the production quality of

It has a traditional wood structure with assembly concept.

It is a fast assembling residence realized through overall standardization.

The author visited the production plant of landmark “landmark housing” group in Edmonton, Alberta, Canada with the delegation of the international precast building annual conference, and shared with you the company’s advanced technology, And compare it with the cast products of bonestructure “steel structure” company.

Therefore, its business is temporarily limited to Calgary and Alberta in western Canada; Bonestructure “steel structure” occupies a special link between architectural design enterprises and steel structure manufacturers to realize the conversion from BIM model to steel structure.

For light steel structure, BIM model is directly transformed into cast light steel structure frame, and any enterprise with processing capacity is entrusted to customize the light steel structure, which will be assembled on site after production.

The assembly process requires professional assembly teams and cranes.

Special tools are required for on-site assembly.

Domestic peers, hurry up to meet the construction industrialization! Disclaimer: the articles and pictures are transferred from the Internet.

If there is infringement or the original copyright owner disagrees.

Basically, it can be suitable for any type of 3D villa designed by Revit and in line with North American architectural standards, and there are no special requirements for the design; The design company familiar with the special steel structure is easy to accept its parameterization requirements.

This condition is too superior to that of domestic workers resident on the construction site.

It has good integrity, but it will be affected by the geographical location of the manufacturer.

The copyright belongs to the original author and the original source.

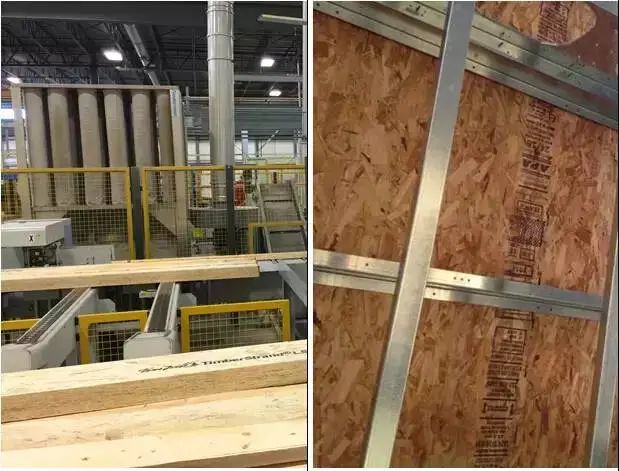

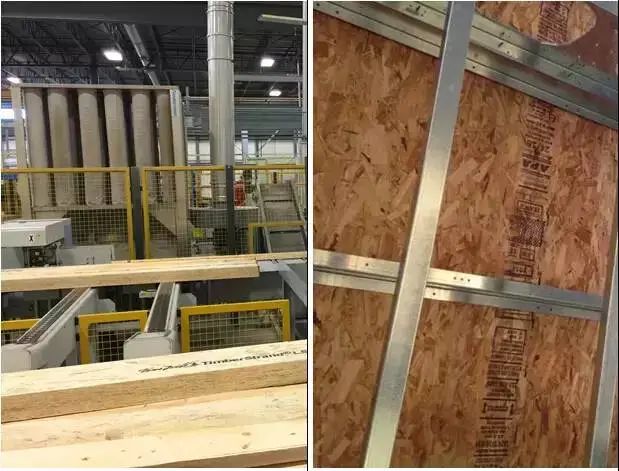

The material is first processed into beams, columns and slabs, and forms walls, floors, roofs and stairs in the workshop.

Because the company can completely outsource processing and assembly, it seems to have more expansion in business.

For building structures with special requirements from customers or designers, the company needs to adjust and deepen the design according to the drawings.

It is a well-known construction company in Quebec, eastern Canada.

How can this production process and processing method cause quality problems?! The most important thing is to fully comply with local building standards and traditional architectural styles.

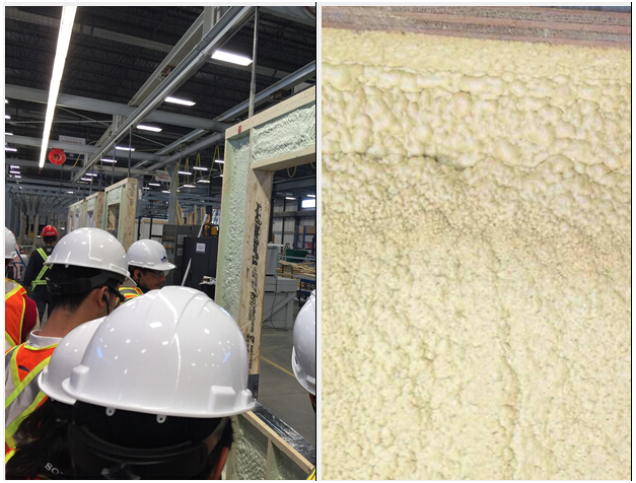

Through highly industrialized processing, the working environment of workers is improved, and the quality of housing production is greatly improved.

Let’s compare them together! 1 “landmark” group “landmark” group is a large-scale real estate construction enterprise “steel structure” company “steel structure” in the western provinces of Canada (Alberta and Calgary).

It has a wood processing plant and can analyze the wood structure of each villa according to the BIM model, And it is directly converted into the wood structure production order in the plant.

2.

▲ for more information, we pay attention to the current mainstream trend of building industrialization of “small house building technology Co., Ltd.” BIM + precast.

Now the time on the construction site has been reduced to two days a day…

BIM (building information model) the company has developed about 120 3D models of standard villas, and decomposed the models into standard size wood that can be produced on the assembly line for rapid production.

III.

Therefore, the business has been expanding in eastern Canada, including Quebec and Ontario, to San Francisco, California and more foreign regions.

Complete the production of insulation layers in the factory.

Complete the exterior decoration of wall stones and the assembly of doors and windows in the factory.

In any case, both enterprises can extremely reduce the on-site production cycle, turning the traditional several weeks to several months into a few working days, greatly saving labor costs and time costs, making the construction project insensitive to the climate of the site.

The light steel frame structure can be assembled directly without tools; Through the above comparison, we can see that landmark “landmark residence” is a logistics system with the production workshop as the core.

Trapezoid Rubber Magnetic Chamfer

Only four workers are required on site.

7.

Complete the exterior decoration and the assembly of doors and windows on the site.

The structures are all frame connectors.

production features: complete the assembly of walls, roofs and floors in the factory.

Precast stairs are hoisted on site, On site hoisting four assembly speed on site two working days on site four working days on site five the overall cost is the same as that of traditional villas of North American Standard and the cost is the same as that of traditional villas of North American standard six the environmental protection site has no pollution, no garbage, no processing, all environmentally friendly green materials, low waste rate in the production process, almost no surplus materials, no pollution, no garbage, no processing on site, all environmentally friendly green materials, low waste rate in the production process, Almost no surplus materials.

This is a great innovation! You should know that on the construction site in Canada, all workers drive their own private cars to work.

After all production is completed, it shall be hoisted on site.