The construction case of a precast farm house is shared, from the foundation to the roof and then to the interior decoration

Today we also share some construction cases of precast houses abroad.

In the case here, the owner is quite particular about it, and made the effect drawing and construction drawing respectively.

However, in this case, the interior decoration also took a lot of time and cost.

If domestic rural houses are built according to experience, they do not make any design drawings at all, so the effect of rural houses is mostly the same.

The foundation pit has been excavated, and the depth is not deep, Therefore, there is no slope protection cushion, leveling the crushed stone layer, and paving the flat extruded board insulation layer, which is standard for energy-saving buildings in foreign countries.

At a glance, the second floor of the precast building is also set up, The whole building is formed.

It is also a box floor composed of wooden materials, which is filled with thermal insulation cotton, Improve the thermal insulation performance and sound insulation.

It is rare in China to lay reinforcement mesh and pour concrete floors, and the finished energy-saving doors and windows are in place.

A glance at the construction site of cast buildings.

At a glance at the construction site of the precast building, you can see the thermal insulation cotton of the ceiling.

This wall slab is a precast wood wall slab with wood as the main body, The precast wooden wallboard with doors, windows and glass is a sandwich thermal insulation structure with very good thermal performance.

After the laying of one layer of composite floor slab, this is to place precast stairs.

In order to combine the cast main structure with the decoration and further save the construction process and time, the real efficiency of the cast system can be improved.

The wallboard on the whole floor has been installed, and the floor slab has been laid quickly.

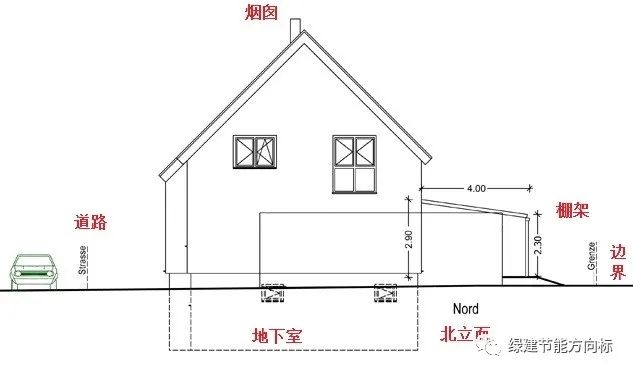

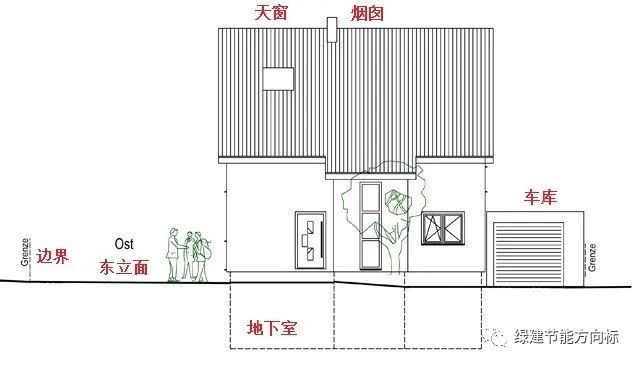

East elevation of the building west elevation of the building south elevation of the building north elevation of the building , building the house starts with foundation treatment.

Assembly type greatly reduces the on-site construction time of civil structure.

Photos of the finished facade of the indoor floor heating pipe laying.

The hole on the wall is backfilled to one layer, and more than one layer of precast wall slab is placed.

The temporary water and electricity must be complete before they can work.

The planning and construction of a building begins with design.

Site selection, point setting and drilling exploration are carried out here to see how the foundation conditions are.

The installation process of slope roof panels.

For precast houses, component splitting is also required for scheme design and construction drawing design.

I hope today’s case can help you…

This is to install the chimney in place, install the roof tiles, install the indoor fresh air duct after the roof tiles are installed, test the air tightness of the blast door on the ground, and lay the floor heating pipe, It shows that floor heating is still required in winter.

A mobile toilet is specially set on the site to facilitate workers to start excavation.

Here is the effect drawing of the building.

The waterproof and protective layer is laid on the outside of the insulation board.

This is the side line point of the soil sample block to be excavated.

The insulation board is pasted on the outside of the basement wall.

This is the installation of slope roof panels.

Photos of the completed facade.

Our large-scale buildings need professional geological exploration units to carry out exploration and provide suggestions on the foundation scheme report.

Internal decoration effect.

Precast buildings are now more and more respected, and various regions of the country have issued policies for compulsory promotion and use.

Internal decoration effect.

This is the laying of precast concrete laminated wallboards, This is the precast concrete composite wall slab of the wall in the basement.