The History of Fabricated Architecture (1)

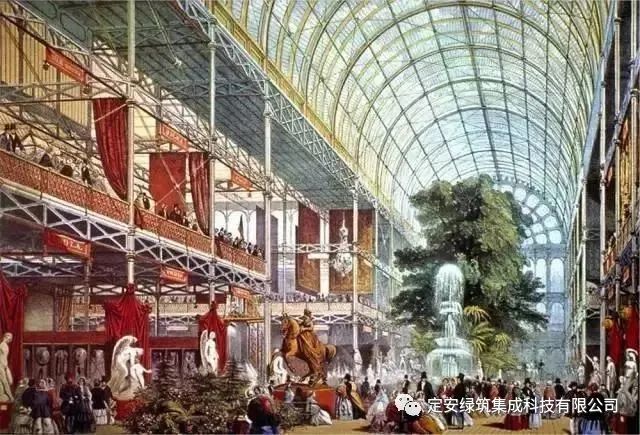

The Crystal Palace in London is being built with precast parts..

The British Empire was in its heyday, and the Queen invited countries around the world to participate in the first World Expo held by the British Empire.

The American Construction Industry Association (CII, 1986) defined pre manufacturing and pre assembly in a basic report as follows: “Prefabrication is a manufacturing method that combines various materials on special equipment to form a final installation component”.

The walls are also built with stone blocks.

The first large precast public building, the Crystal Palace in London, was completed in less than six months, with a width of 408 feet (about 124.4 meters), a length of 1851 feet (about 564 meters), a total of five spans, three floors and a building area of about 74000 square meters.

For example, in ancient times (Hemudu culture), China created the “tenon and mortise structure” of “beam column type” buildings, and began to implement the “cast architecture”, which has been handed down to this day.

Around 600 BC, timber columns underwent a material revolution called petrification, and all columns were made of stone and pre manufactured.

From the ancient times of “winter is camp cave, summer is nest” to today, all buildings created by human beings are basically “precast buildings”.

Stone columns are stacked with drum shaped blocks, and the blocks are connected with mortise tenons or metal pins.

The Crystal Palace has gone through the whole process from design conception, production, transportation to final construction and demolition.

The tenon and mortise structure for fixing vertical members, the wooden tenon and mortise excavated from the Neolithic Cultural Site in Hemudu, Yuyao, Zhejiang Province, is the earliest precast building component found in the world by archaeology so far.

He hoped that the construction industry would “batch copy” buildings like cars in the first half of the 20th century.

2、 Early precast buildings In a broad sense, precast buildings include many modern and ancient building technologies.

1、 Definition of precast architecture In 1921, the concept of “building a house like a car” was first mentioned by French master architect Le Corbusier in “Towards a New Building”.

The British Construction Industry Research and Information Association (CIRIA, 1997) defines pre assembly as follows: “Pre assembly: organize and complete most of the final assembly work for a product before it is finally in place.

The structure of ancient Greek architecture belongs to the beam column system, and the early main buildings were all made of stone.

The first industrial revolution was basically completed around 1850, and Britain became the first industrial country in the world.

Due to material performance, the span of stone beam is generally 4-5 meters, and the maximum is 7-8 meters.

Although it is carried by horse, it pioneered the technical model of factory precast components and on-site assembly, which is the pioneer of modern architecture (steel skeleton and glass curtain wall).

Joseph Paxton, relying on the economy, accuracy and rapidity provided by modern industrial technology, completely adopted the continuous production mode of unit parts for the first time, built a large space by means of assembly structure, and designed and built the Crystal Palace of London World Expo.

In the development process of precast buildings, in view of the differences in historical background, economic basis, technical level and development goals of various countries, the development of precast buildings at home and abroad presents different characteristics.

It includes many forms of sub assembly.

Ancient Greek buildings from the 8th to the 6th century BC were all made of wood, mud bricks or clay.

The ancient precast wooden frame system in China is the same.

Bricks and blocks used in most parts of the world are probably the simplest precast components.

It is a complete precast construction system project.

It can be carried out on site or away from the site, and often involves standardization”.