The integration technology of Heneng precast decoration parts is included in the list of “advanced, mature and applicable new technologies”

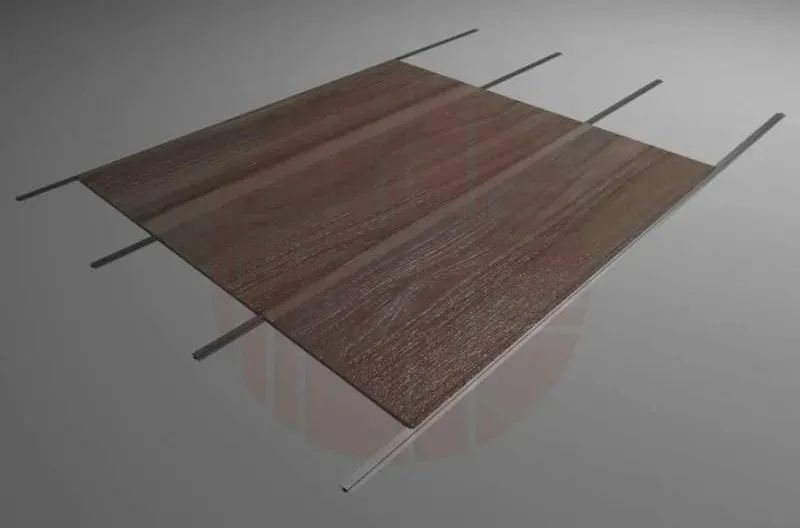

The heating pipe and extruded board with thermal insulation are added to realize the ground heating with high heat dissipation rate on the ground and form a section steel composite floor heating module.

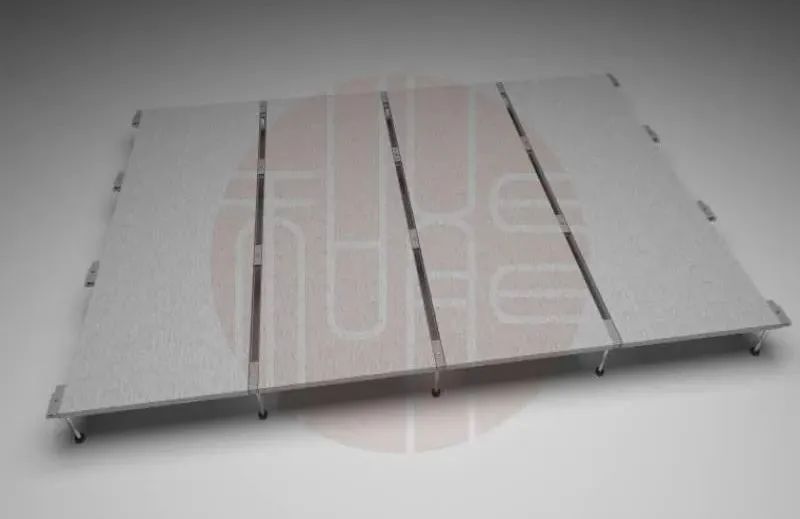

(2) Quick installation floor system: Based on the overhead ground system, the dry construction method is adopted to realize the rapid decoration of the ground.

In order to quickly locate the water outlet of the water supply pipe, a special water pipe reinforcement plate is set, which is subdivided into water pipe drum double headed plate, water pipe reinforcement single head plate and water pipe reinforcement U-shaped plate according to the application position.

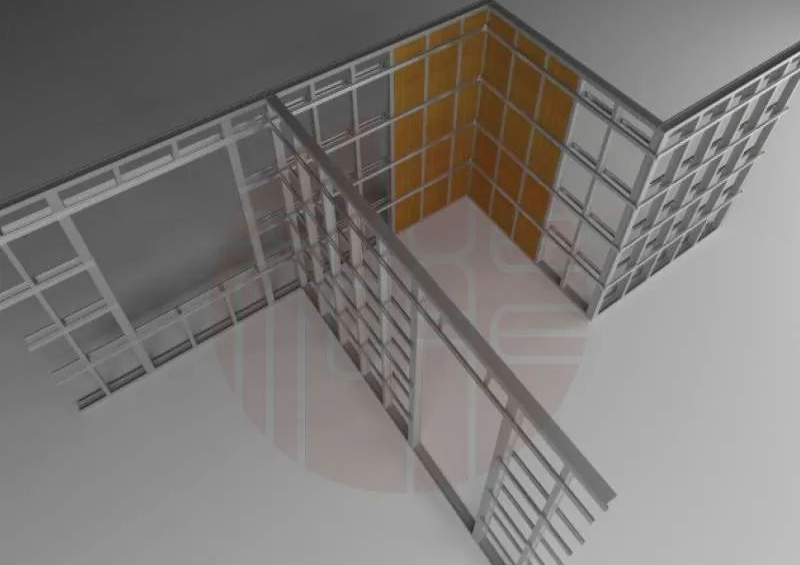

(4) Light partition wall system: mainly light steel keel calcium silicate board light partition wall and modular partition wall.

The moisture-proof structure is to lay a layer of PE waterproof and moisture-proof membrane in the wallboard to prevent the water vapor in the bathroom from entering the wall, and the condensed water formed on the surface of PE membrane is led back to the thermoplastic composite waterproof chassis.

(6) Integrated ceiling system: the components involved mainly include self decorative panels and connecting parts.

(8) Quick installation water supply system: it mainly refers to the quick installation technical part of aluminum-plastic composite pipe.

(5) Quick installation wall system: the system is an integrated wall installed on site by dry construction method on the wall base of existing flat wall, light steel keel partition wall or uneven structural wall.

The self facing calcium silicate composite floor is adopted, and each floor is connected with module connecting fasteners.

In terms of reinforcement structure, because the integrated wall of the assembly decoration has an overhead layer, the kitchen hanging cabinet with more than 15kg needs to be preset with a reinforced transverse keel, which can be connected with the structural wall or the vertical keel support.

02 technical index (1) main performance 1) sound insulation performance: the air sound insulation capacity of light partition wall is between 48dB and 55dB, which is different for different series of products.

The finishing composite technology of self decorative roof is the same as that of integrated wallboard.

When the cladding finishing technology is adopted for the top plate, the several shaped aluminum profile and the upper shaped aluminum profile can be combined with the same finishing material to enhance the sense of unity.

For partition wall or structural wall, special parts can quickly level the wall surface, and the surface of wall plate substrate is integrated with wallpaper, wood grain, stone and other texture effects.

The water pipe is divided into cold water pipe, hot water pipe and medium water pipe according to the use function.

After careful evaluation and selection by the expert group, the integration technology of Heneng precast decoration components was successfully included in the list of “advanced, mature and applicable new technologies” of optional buildings.

For the sake of error prevention, the color is divided and applied according to white, red and green respectively.

The waterproof of thin method overhead is connected with the special floor drain and fixed with sealing ring and special bolts.

Among them, the overhead module realizes the three in one of overhead, leveling and support functions.

The depth of the floor drain meets the needs of preventing anti odor and centralized drainage in the toilet.

On the roof, various openings such as ventilator, Yuba, smoke exhaust pipe and embedded lamps can be reserved according to the needs of equipment configuration.

Instead, the secondary purified oil fume is directly discharged outdoors through the aluminum foil flue in the ceiling.

The specific technical contents are as follows: (1) overhead ground system: on the premise of avoiding plastering wet operation, the system realizes pipeline laying, support, leveling and ground decoration in the space under the floor.

In terms of smoke exhaust structure, the integrated kitchen is generally no longer equipped with indoor smoke exhaust duct to avoid public odor.

3) Heating performance: the heat dissipation of the floor heating module is greater than 112.4w / ㎡, up to 151w / ㎡..

The focus of the parts is on high integration.

The technical content of the integration technology 01 of Heneng assembled decoration parts and the integration technology of capable people’s house assembled decoration parts are based on Si theory, using standardized components and parts to design, produce integrated and modular decoration parts, and carry out combined installation on site.

The floor drain, shower, washbasin, washing machine and other drainage are drained in the thin method space under the overall waterproof chassis of the toilet and discharged to the public area pipe well on the same floor horizontally.

The connection structure of the drainage pipe is connected by socket and spigot at the rotary cutting connection port, and the sealing ring is arranged to reduce the water leakage at the connection of the drainage pipe.

2) Fire resistance: the fire resistance time of light partition wall is more than 1 hour, and the fire resistance grade of calcium silicate composite floor is B1 flame retardant.

In order to avoid smoke pouring, the stainless steel hood is installed on the outer enclosure wall, and the range hood with purification efficiency of more than 90% is the key control point.

(3) Integrated heating system: the system is further integrated on the basis of overhead ground.

(9) Integrated bathroom system: it is composed of waterproof and moisture-proof structure, exhaust and ventilation structure, ground structure, wall structure, ceiling structure, ceramic sanitary ware, electrical and functional hardware of dry construction method, and the most prominent is waterproof and moisture-proof structure.

It has strong flexibility and can be filled with environmental sound insulation materials to reduce noise.

The support structure uses the adjustable socket card of the drainage pipe on the same floor to fix the drainage pipe.

Along the length direction between the top plates, the upper shaped aluminum profile is used to float and lap in the form of open keel.

For large electrical equipment such as range hood and water heater, the reinforcement plate shall be embedded on the structural wall or the vertical keel support.

One part is the drainage behind the toilet on the overhead ground, and the other part is the drainage pipe under the overhead ground.

The fixed-length aluminum-plastic pipe is installed with clamping parts in the factory.

It is suitable for any indoor partition wall.

In order to comprehensively sort out and summarize the technical achievements of the development of precast buildings in recent years and promote the wide promotion and application of advanced, mature and applicable new technologies, the construction industry modernization development committee of China Architectural Society organized and carried out the collection activity of “advanced, mature and applicable new technologies” of precast buildings.

(10) Integrated kitchen system: the technology of wall top ground structure is the same as that of quick installation wall surface, integrated ceiling and quick installation floor system, and the technical focus is on smoke exhaust structure and hanging cabinet reinforcement structure.

(7) Thin method drainage system: it is a thin method drainage part on the same floor based on the non falling plate of the main structure.

The activity received positive response and extensive participation from the industry.

It is composed of self facing calcium silicate composite wall panel or dry composite ceramic tile and connecting parts, and uses special parts to quickly level the wall.