The whole construction process of assembled underground garage laminated plate will teach you step by step!

After the construction of cast-in-place frame beam and frame column is completed, the construction of cast-in-place frame beam shall be started, including supporting bottom formwork, binding reinforcement, beam side formwork reinforcement, etc.

Inspection and acceptance before concrete pouring, inspection and acceptance shall be carried out for items such as the installation of laminated plates and on-site reinforcement binding according to relevant specifications.

Floor support installation construction floor support installation shall be arranged according to the requirements of the design drawings, and shall be conducted alternately with the frame beam construction to minimize the construction period.

Composite floor support design node drawing composite floor support installation node drawing composite floor and beam connection design drawing composite floor and beam connection installation drawing composite wallboard and bottom plate connection installation drawing composite wallboard and bottom plate connection installation drawing composite wallboard and top plate connection installation drawing composite wallboard and top plate connection installation drawing composite wallboard horizontal joint design drawing composite wallboard horizontal joint installation drawing composite wallboard joint design drawing composite wallboard joint installation drawing It is recommended that you long press the QR code to add several architectural micro signals..

The water wire box and pipeline on the water and electricity pipeline connection laminated floor will be reserved in advance in the production stage.

Hoisting of laminated wallboard the laminated wallboard shall be hoisted as required, and each wallboard shall be fixed and adjusted with two inclined supports.

After installation, it is only necessary to connect their pipelines on site.

Generally, the joint mortar and wood strip can be used.

After the bottom of the precast wallboard and the jointed wallboard are hoisted, the workers can carry out the joint treatment.

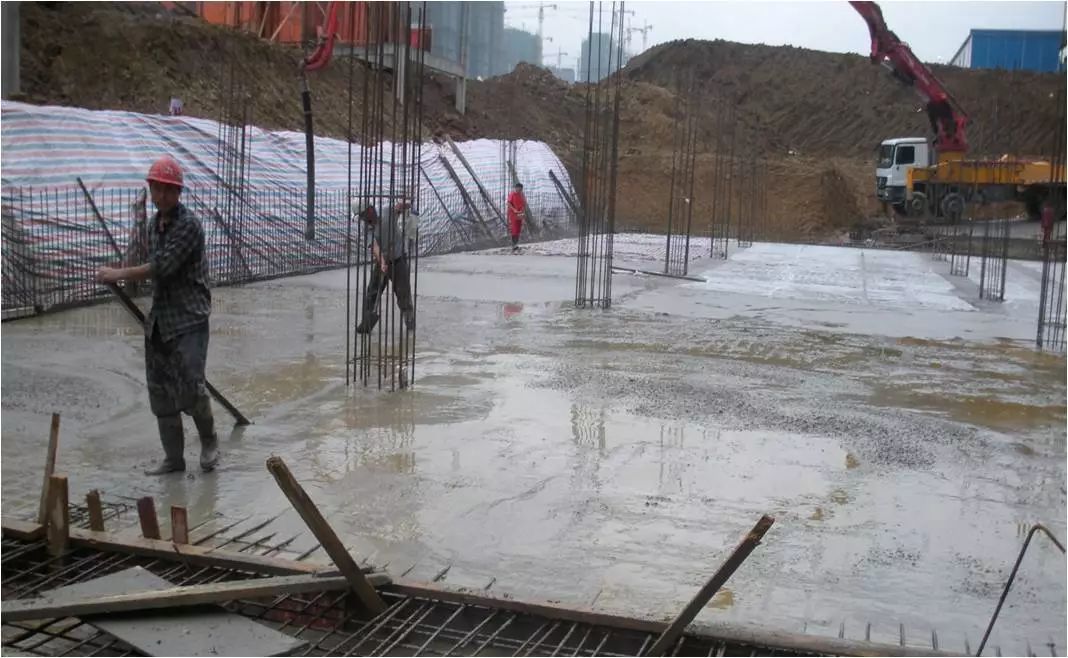

Source: the construction of foundation slab for dragon building construction is consistent with the traditional construction method, but the size and position of the reserved vertical joint reinforcement of the wall are strictly required.

Installation of upper floor reinforcement the upper floor reinforcement shall be placed on the upper chord reinforcement of the lattice beam and bound with the lattice beam to prevent offset and floating during concrete pouring.

The reserved dowel bars shall be checked and adjusted after the construction of the foundation slab is completed.

The vertical reinforcement of the wall reserved for the foundation shall be checked and adjusted before the wall slab is hoisted.

Before the wall panel is hoisted, the foundation surface of the bottom plate shall be measured, and the horizontal elevation control pad shall be placed at the lower foot of each wall panel.

The pouring height of each layer shall not be greater than 80cm, and the interval shall not be less than 1 hour.

Concrete pouring concrete pouring shall start from the wallboard, and shall be poured in layers.

After the construction of cast-in-place frame column and the installation of laminated wallboard, the construction of cast-in-place frame column can be carried out, including reinforcement binding, formwork erection, concrete pouring, formwork removal, etc.

Hoisting construction of composite floor slab hoisting of composite floor slab shall be carried out in accordance with the installation layout in the design drawing, which has detailed floor number, size and position.

Hoisting of laminated wallboard the hoisting of laminated wallboard shall be carried out in sections according to the scheme prepared in advance, and moving cranes and tools shall be minimized.