Unilateral and optimization points of precast components in precast buildings

The final calculation affects about 75 yuan / m2 per square meter; 1.

At present, most laminated plates are reinforced on four sides (detail III) has a great impact on the construction difficulty and construction cost, and the corresponding impact will be reduced when the laminated plate process is more mature and a new form of precast laminated plate appears; 3.

Fixing Socket Cross Pin Nail Plate

The precast components of the project include: precast stairs, precast diaphragm walls and precast laminated plates.

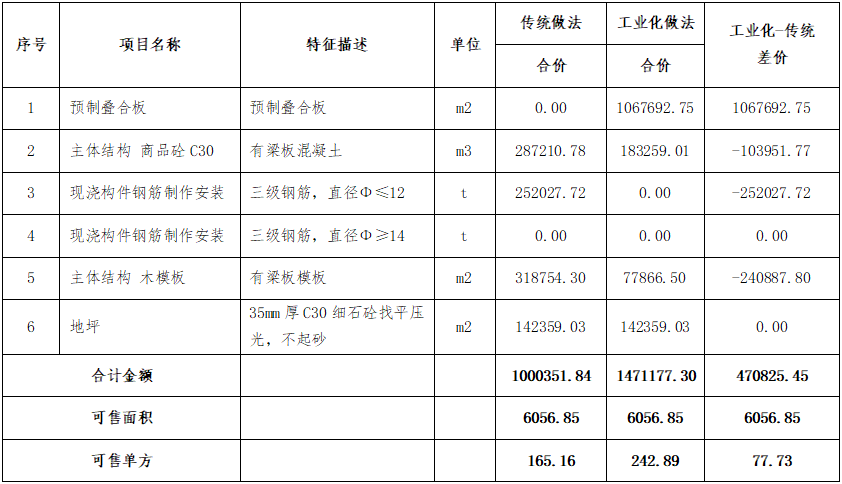

The precast part of reinforcement and formwork are included in the unit price of precast concrete, and the decoration method remains unchanged; while the cast-in-situ floor slab is considered 130mm thick.

According to the calculation of other cast projects, the unilateral impact will increase by about 100 yuan / m2 for every 10% increase in prefabrication rate; Compared with conventional methods, the cost of precast buildings under foreign mature technology is actually lower than that of conventional buildings, which has many advantages, such as reducing construction cycle, reducing later maintenance cost, energy conservation and emission reduction, reducing labor cost and so on.

National policies, Party A’s management mode, design assembly thinking, high standardization of manufacturers and these matters at the front end of the project cycle all affect the cost of dress matching buildings.

Theoretically, due to the high precision of precast components, it can be considered to cancel or reduce the leveling thickness and directly carry out putty construction, which can correspondingly reduce the decoration cost; 2.

In order to meet the pipe embedding demand, the cast-in-situ floor slab is partially reinforced For thickness thickening, if the “pipeline separation” process can be considered, the thickness of the corresponding laminated plate can be reduced, and the main reinforcement and other components responding to the reduction of ground load can be reduced, which also facilitates the maintenance of pipelines in the later stage of the project; 2.

With the maturity of precast partition wall technology, the price of main materials will gradually decrease, Moreover, the precast partition wall cancels the secondary structure of conventional buildings, which also helps to shorten the construction period of the project; ③ Picture of precast laminated slab affecting single square member: (precast composite slab) the composite slab is 60mm precast 80mm, with an overall thickness of 140mm.

▲ click the picture to sign up for the engineer conference.

▲ click the card at the top to pay attention.

The author Zhang Longyu cited that since the beginning of 2016, precast buildings have been paid more and more attention by the government and the construction party.

1、 The project is located in the urban area of a city in East China, with a total construction area of more than 200000 m2; My role in the project: background Civil Engineering Project Manager II.

With the rapid development of precast buildings in China, it is believed that the domestic precast building technology can also be in the forefront of the world in the near future.

This time, a typical residential project is selected to share the common precast components of the project.

Party A asked about the unilateral impact of precast buildings and the impact points; Precautions and optimization suggestions.

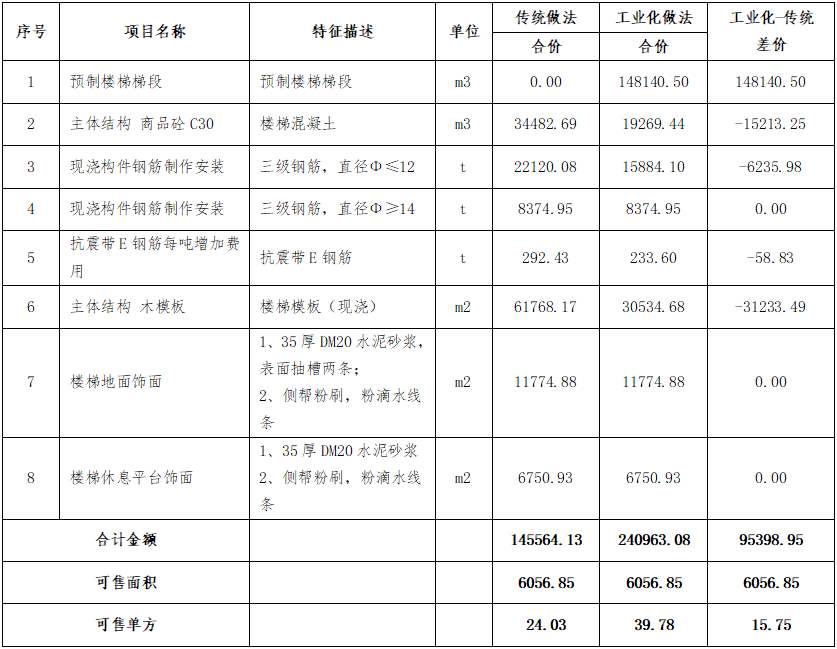

① Picture of precast stair unilateral component: (precast stairs) rest platforms are considered as cast-in-situ, precast stair formwork and reinforcement are included in the unit price of precast concrete, and the decoration practices are not adjusted according to the Convention; the unilateral impact of the project practice comparison is 15 yuan / ㎡; 1.

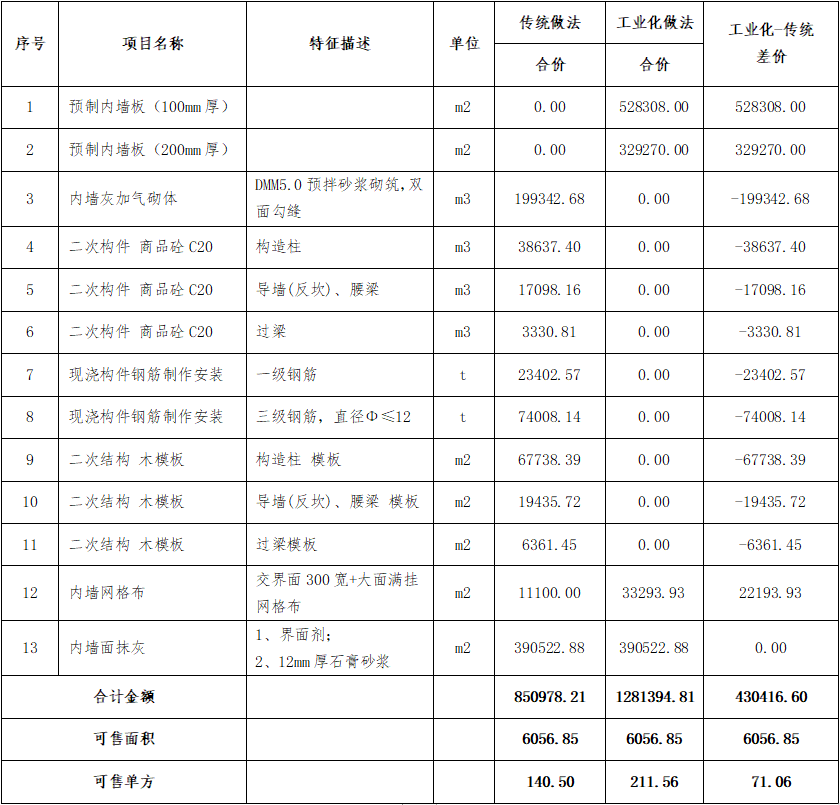

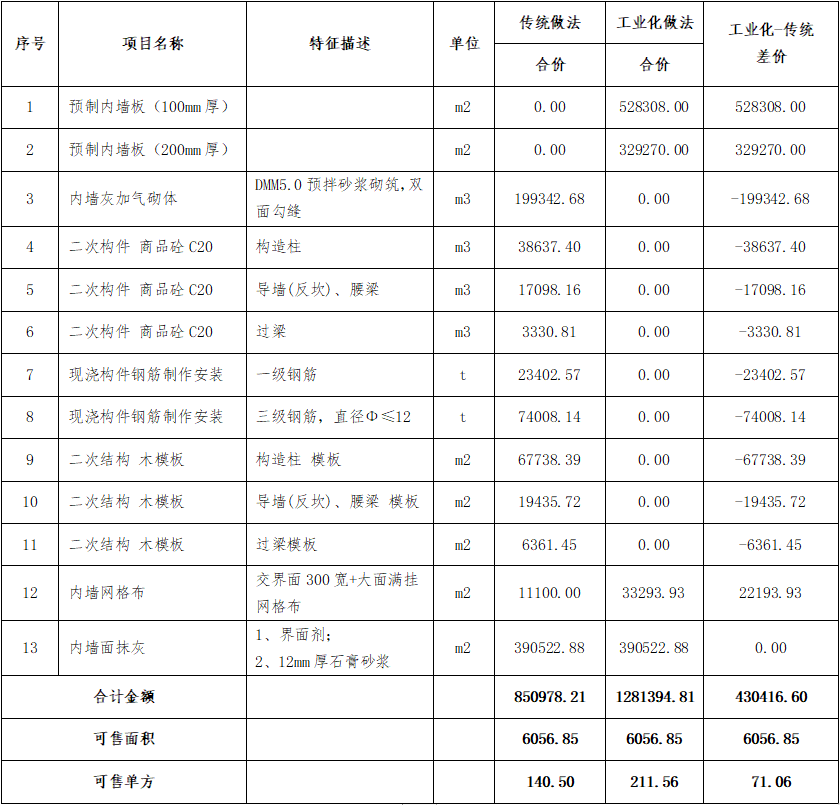

In addition, the cost of main materials will be reduced with the gradual maturity of prefabrication process In case of low cost, the cost of final precast stairs may be lower than that of cast-in-situ stairs; ② Picture of precast internal partition affecting unilateral components: (precast internal partition wall) the prefabrication method cancels the secondary structure, and the decoration part is considered according to the conventional method, which increases the cost by about 70 yuan / m2 per square meter; 1.

Case background: the promotion of precast buildings.

However, at present, the cost of most existing projects is increasing, and the benefits of assembly have not been reflected.

The real big head is at the front end.

Since the bottom of the laminated plate is a precast component, in theory, the internal full scaffold can be cancelled, and the independent support for the post cast strip of the laminated plate can be considered to reduce the cost of some measures; 4.

The following article comes from the old company’s machine disk cost.

The thickening of the composite slab is because the central line pipe is embedded in the cast-in-situ slab in the traditional process.

The increased cost of measure cost mainly comes from the scattered manufacturers of precast components, which increases the transportation cost of components, and the large self weight of precast components increases the vertical transportation cost; 4、 To sum up, on the whole, the prefabrication rate of the residential project is 30%, and the additional design cost should be about 240 yuan / m2.

3、 The unilateral analysis case selects a project to analyze the individual impact of precast components of each project, and gives some suggestions on optimizing space for each precast component.

If it can be considered that the optimization of the decoration of precast stair flight can be cancelled, the cost of precast components can be reduced; 2.

The central government and the State Council proposed to take about 10 years to make the proportion of precast buildings reach 30% of new buildings, In response to the national call, all localities have made specific requirements for assembly rate and prefabrication rate for new projects of corresponding specifications; So that during many interviews, Party A has raised questions about the precast building, and the key questions are about the impact of the precast building and whether there are some optimization suggestions for the precast building.

If you want to see more assembly video information, enter the video number at the bottom ~ “China Construction Industrialization Engineer conference, click the applet to sign up” and “hot article recommendation of this issue” click on the lower left corner“.

In theory Due to the high precision of precast components of the laminated floor itself, some ceiling decoration and ceiling can also be optimized Shed repair work to reduce some decoration costs; ④ Overall impact unilateral: 1 Considering the need for design of precast buildings, issuing detailed drawings will increase the design cost; When the specification and design of precast components are more mature, it is expected to reduce some costs; 2.

In fact, the role of actual construction in reducing costs is relatively small.