What are the common connection modes of precast concrete structures

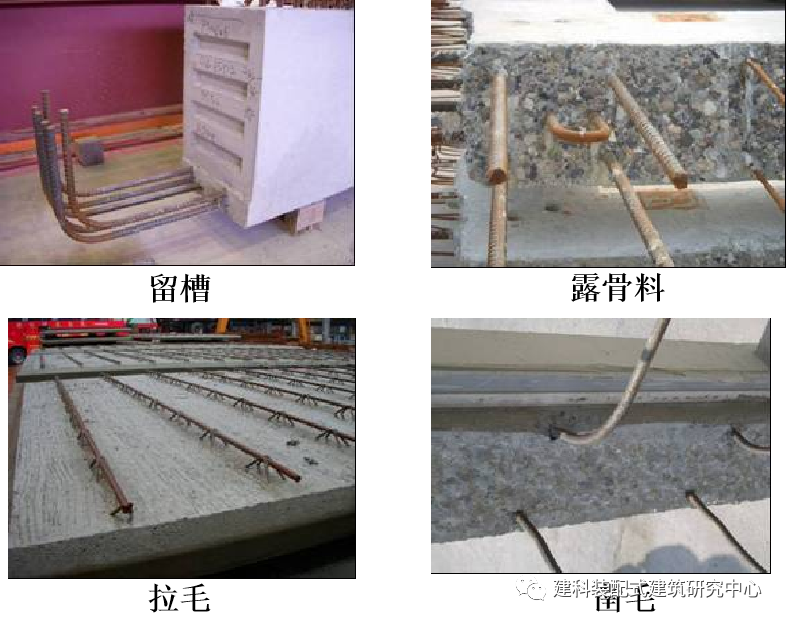

At present, there are many kinds of hole forming technologies in China, and there is no unified demonstration.

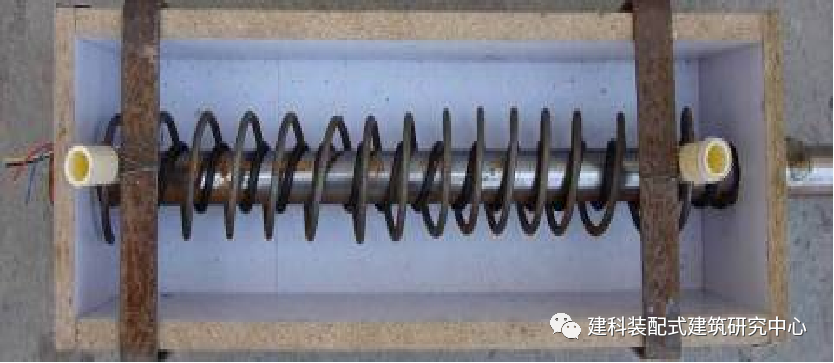

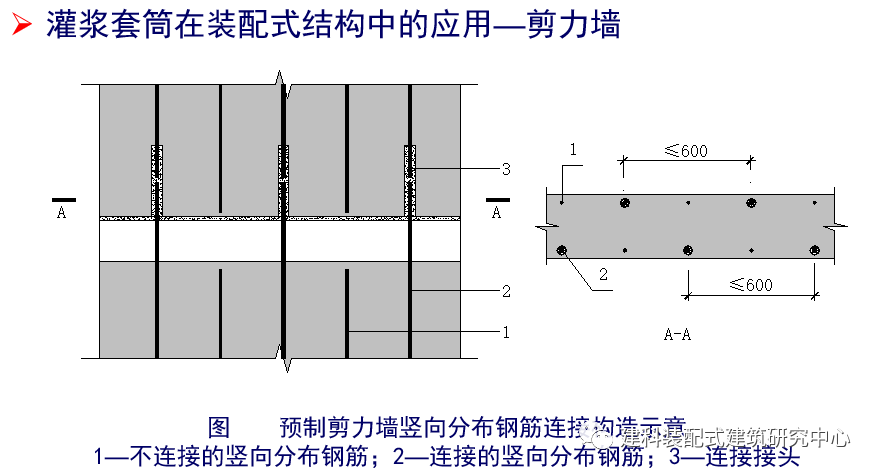

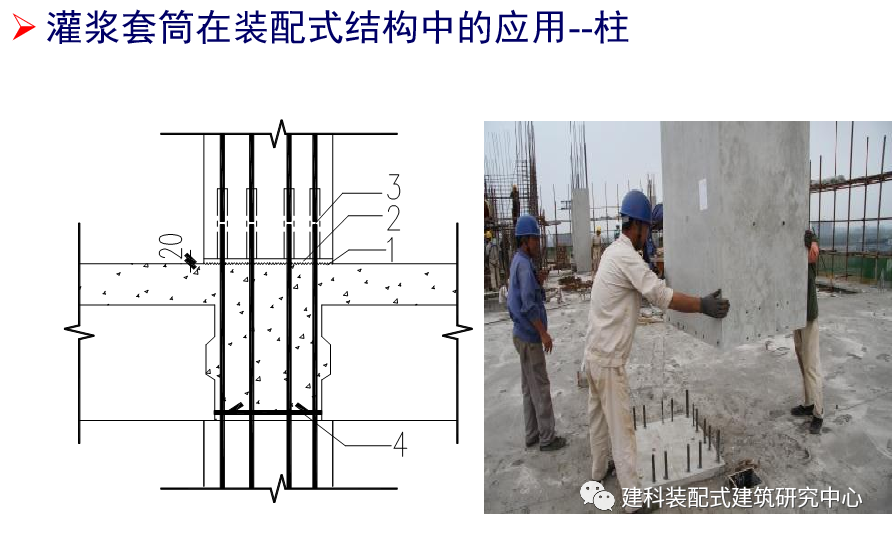

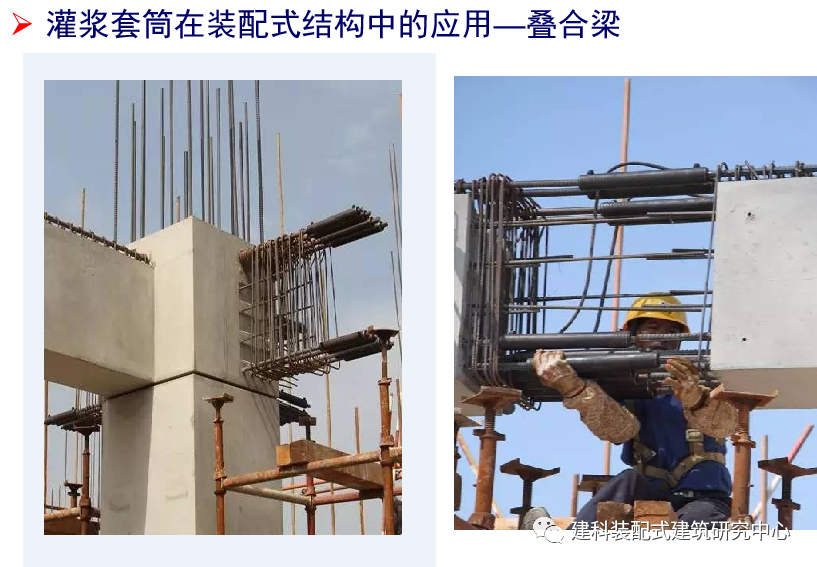

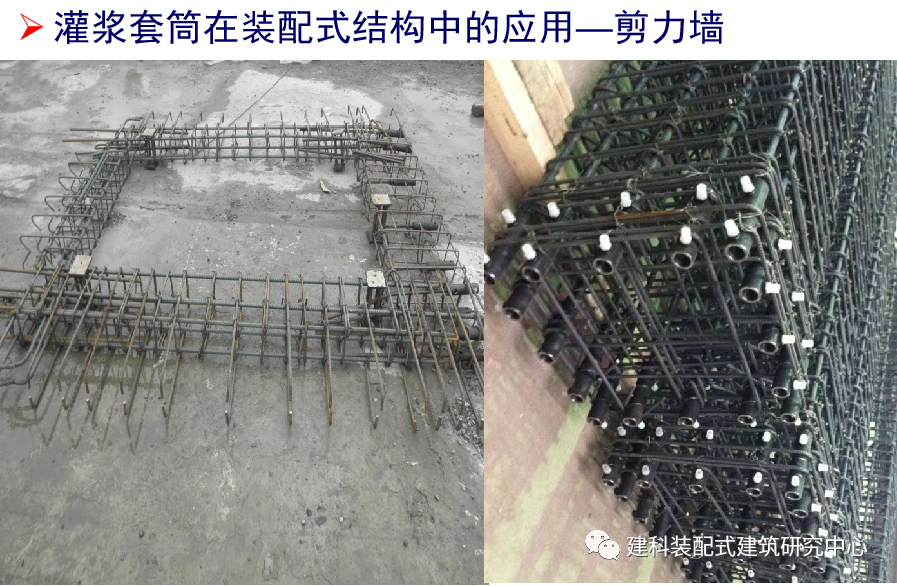

The full grouting sleeve and half grouting sleeve reinforcement sleeve grouting connection is mainly used for the connection of longitudinal stressed reinforcement of shear wall and precast column of precast concrete structure; It can also be used for longitudinal reinforcement connection of post cast parts such as composite beams.

The connection mode of post cast concrete reinforcement can adopt the connection mode of cast-in-situ structural reinforcement, mainly including mechanical thread sleeve connection, reinforcement lapping, reinforcement welding, etc.

The connection modes of precast concrete structure include: 1 Reinforcement sleeve grouting connection is divided into full grouting sleeve and semi grouting sleeve.

The cast-in-situ concrete in the connection area or overlapping part becomes post cast concrete.

4.

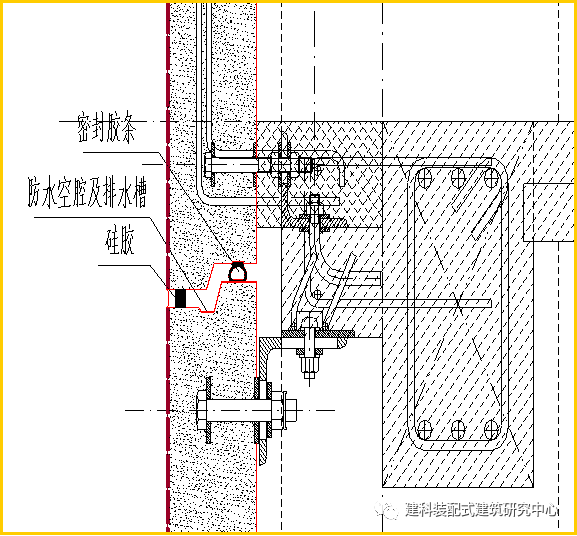

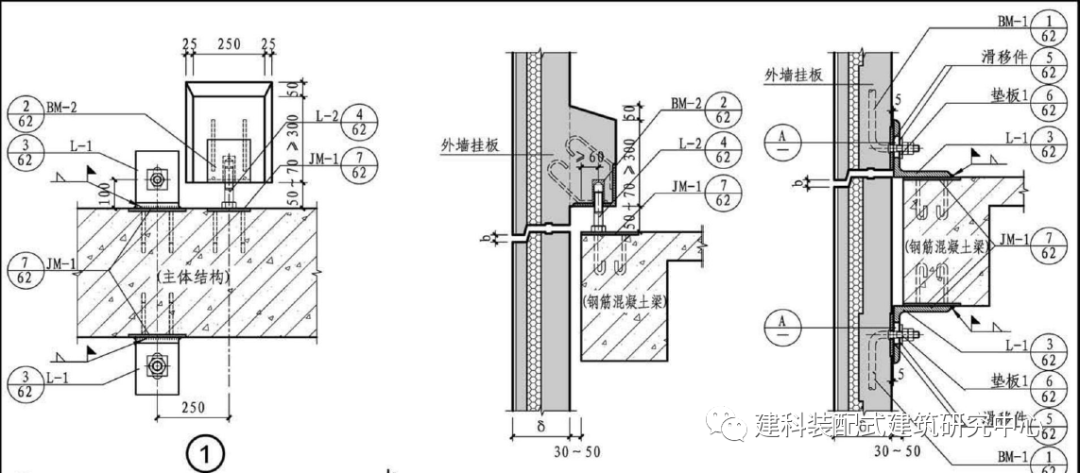

Scope of application of bolted connection: in cast concrete structures, bolted connection is only used for the connection of non main structural components such as external wall panels and stairs.

2.

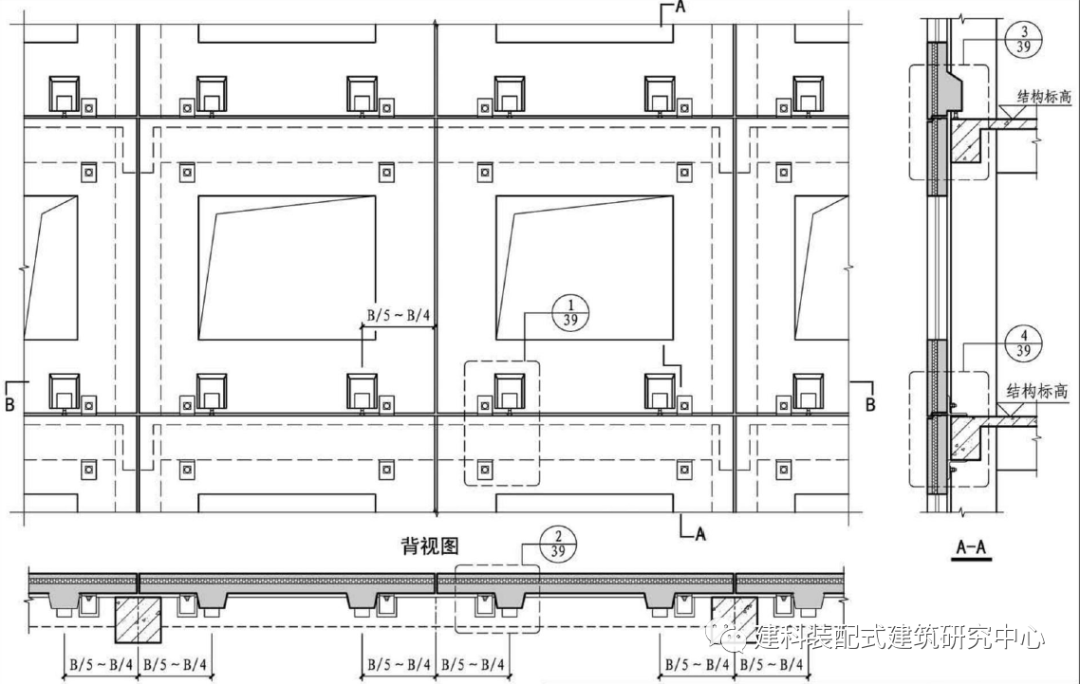

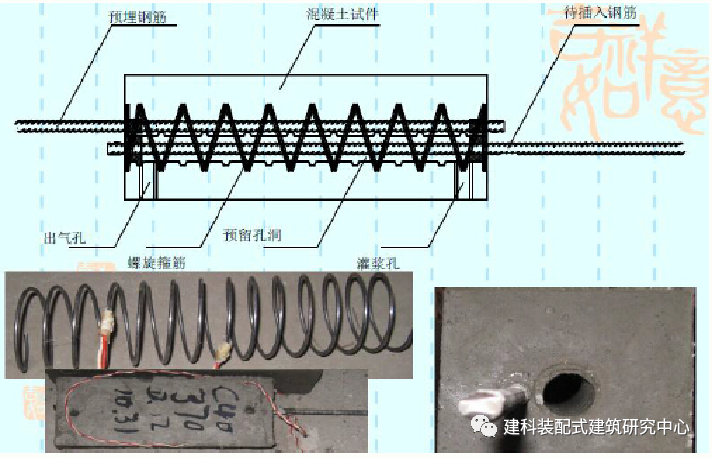

Vertical holes are reserved in the lower section of the vertical structural members, the inner wall surface of the hole is left with threaded rough surface, and the surrounding is equipped with transverse restraint spiral stirrups.

Bolt connection bolt connection: refers to a connection method that connects precast components with precast components or precast components with the main structure with bolts and embedded parts.

Articles and pictures are for learning purposes only, such as copyright issues or disagreements.

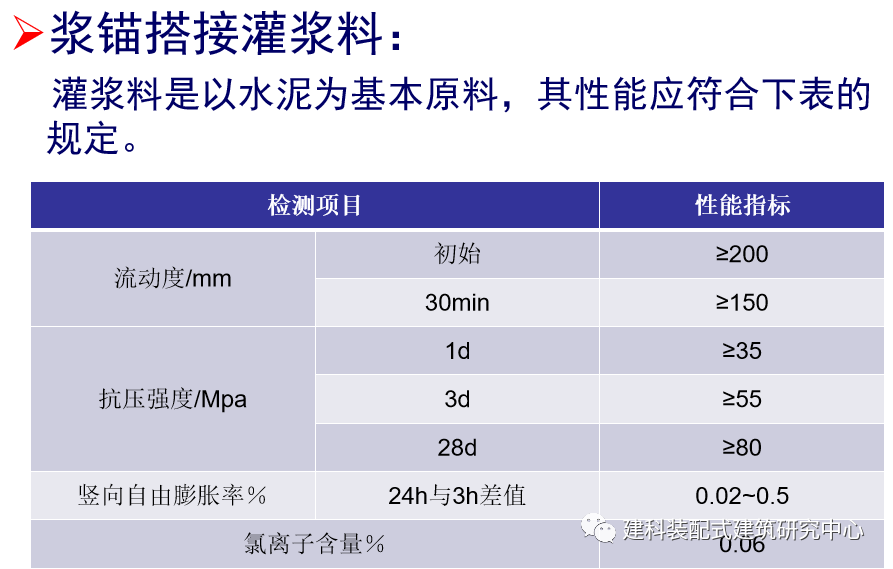

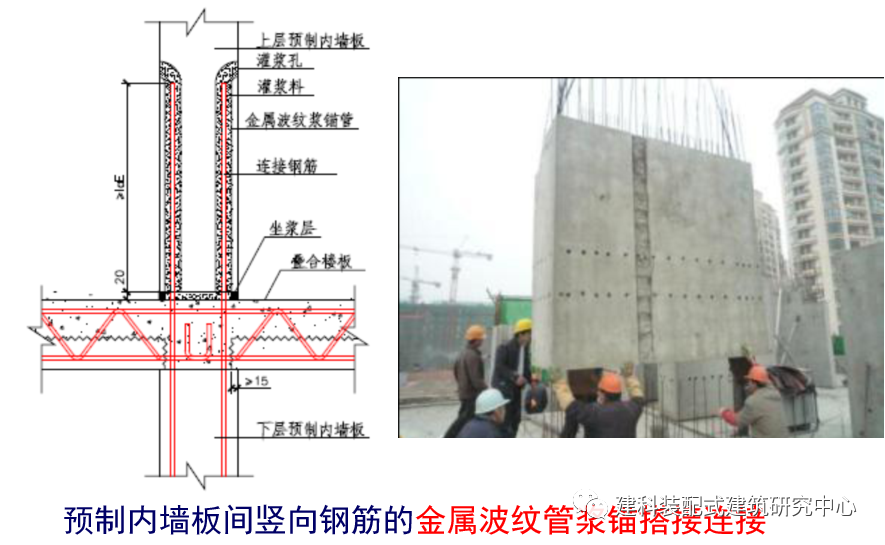

Therefore, the specification requires that when the longitudinal reinforcement is overlapped and connected with slurry anchor, the mechanical properties and applicability of the reserved hole forming process, channel shape and length, structural requirements, grouting material and connected reinforcement should be tested and verified.

Mortar anchor lap connection 3 Post cast concrete connection 4 Bolted connection 1 Sleeve grouting connection the grouting sleeve is a metal cylinder used for reinforcement connection.

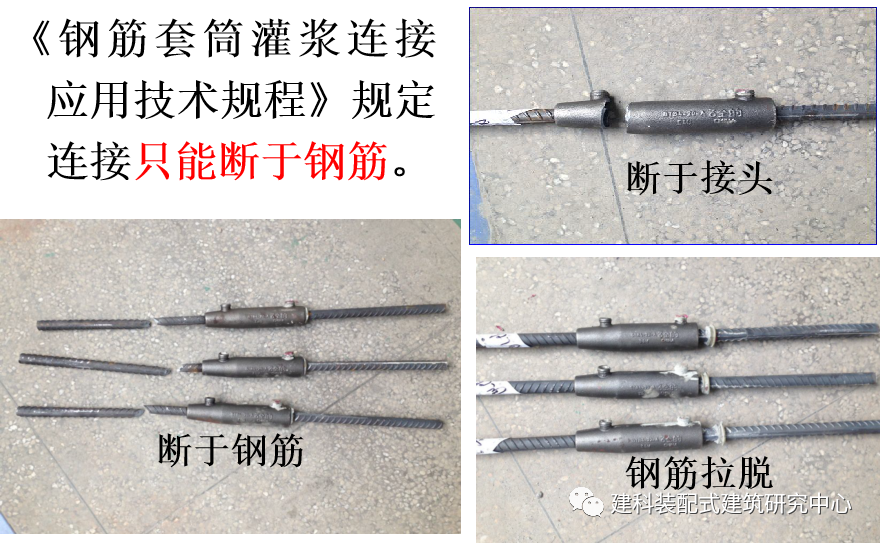

One end is connected by sleeve grouting, and the other end is connected by mechanical connection (such as screw).

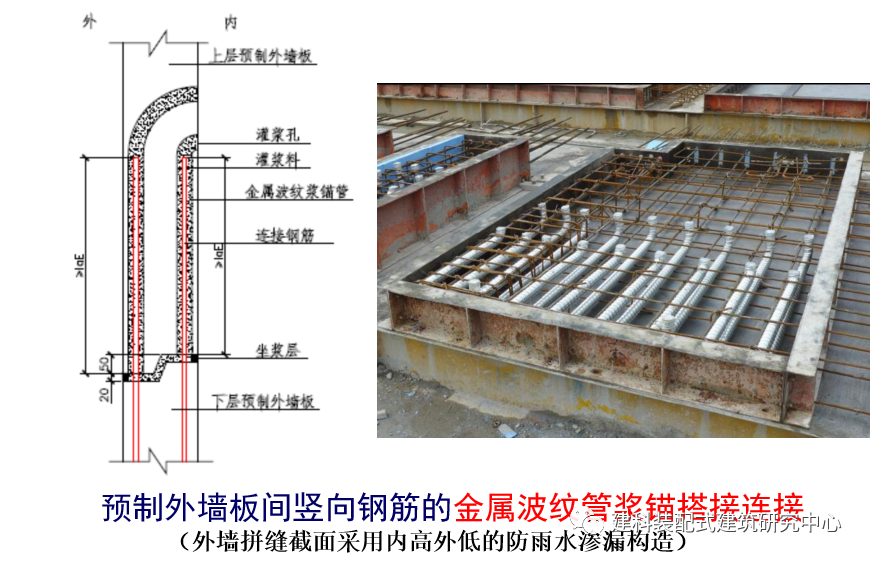

Slurry anchor lap connection slurry anchor lap connection refers to the reinforcement lap connection mode realized by inserting the reinforcement to be overlapped into the hole made by special process in the precast concrete component and pouring cement-based grouting material.

For cast structures, “reliable connection mode” is the first important and the most basic guarantee of structural safety.

Mortar anchor lap joint is a method of connection based on the principle of bonding and anchoring.

Two steel bars are inserted from both ends of the sleeve, the sleeve is filled with cement-based grouting material, and the steel bar butt joint is realized through the force transmission of the grouting material.

The key of slurry anchor lap joint technology lies in the hole forming technology, the quality of grouting material and the method of restraining the overlapped reinforcement.

Sleeve grouting materials are used at both ends, and the sleeve connected is full grouting sleeve.

3.

The tensile strength of the grouting joint of the reinforcement sleeve shall not be less than the standard value of the tensile strength of the connecting reinforcement, and the reinforcement outside the joint shall be broken in case of damage.

Grouting sleeve is the most important connecting component of precast concrete structure, which is used for the connection of longitudinal stressed reinforcement.

Bolt connection belongs to dry connection; Reinforcement sleeve grouting connection, mortar anchor overlapping and post cast concrete connection all belong to wet connection.

The sleeve connected is semi grouting sleeve.

Post cast concrete connection post cast concrete refers to the concrete poured on site in the connection area or laminated layer of precast members after the installation of precast members.

In the cast structure, the cast-in-situ concrete of the foundation, first floor, podium, top floor and other parts becomes the cast-in-situ concrete.

2.

The reserved reinforcement of the lower cast precast members is inserted into the hole, and the upper and lower members are connected into one by injecting grouting material into the grouting hole.